Introduction

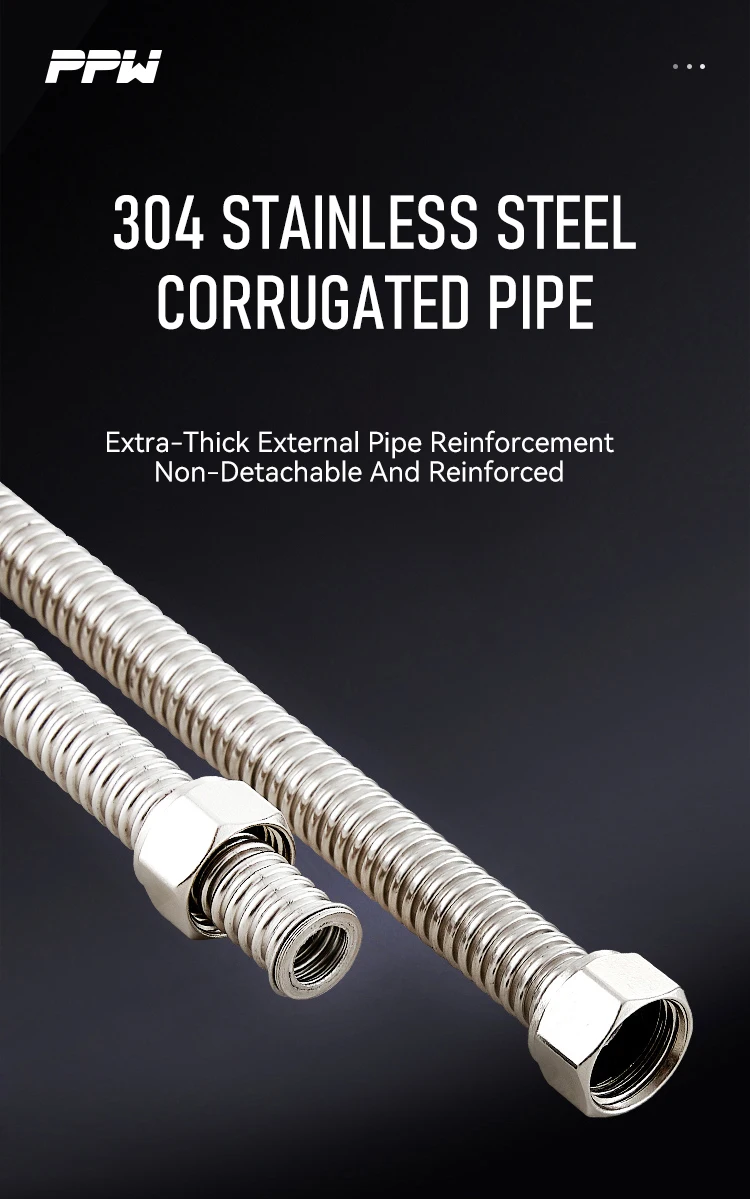

The modern plumbing industry demands reliable, durable, and flexible solutions that can withstand the rigorous demands of residential and commercial applications. The Corrugated Plated 304 Stainless Steel Water Heater Hose Flexible Corrosion & Chemical Resistant for Bathroom Toilet represents a pinnacle of engineering excellence, combining superior material composition with innovative design to deliver unmatched performance in water supply systems. This premium flexible hose solution addresses the critical need for corrosion-resistant plumbing components that maintain structural integrity while providing essential flexibility for installation and long-term operation.

As infrastructure development continues to expand globally, the requirement for high-quality plumbing components has never been more significant. This advanced water heater hose integrates seamlessly into various bathroom and toilet applications, offering contractors, installers, and facility managers a dependable solution that reduces maintenance concerns while ensuring optimal water flow characteristics. The sophisticated corrugated design enhances flexibility without compromising pressure resistance, making it an ideal choice for both new construction projects and renovation applications where space constraints demand adaptable plumbing solutions.

Product Overview

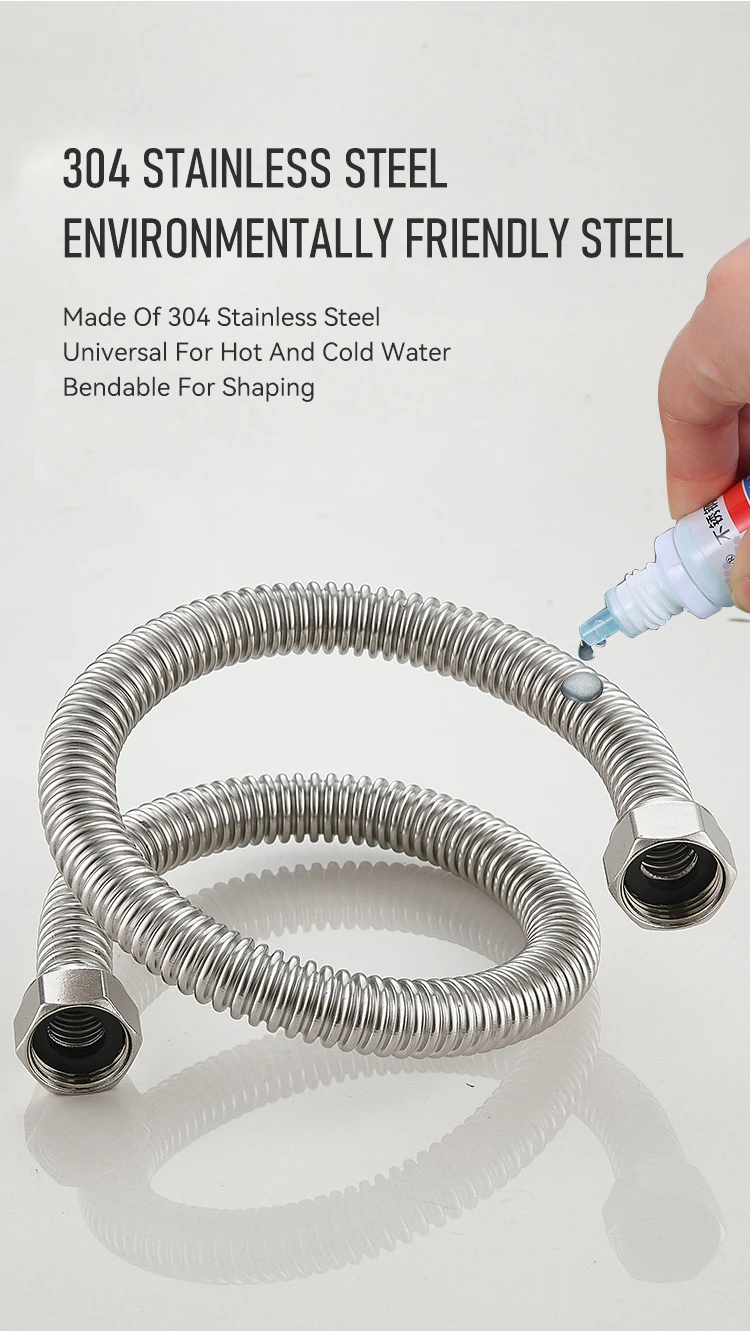

This exceptional water heater hose showcases the superior properties of premium stainless steel construction, specifically engineered to meet the demanding requirements of modern plumbing systems. The corrugated design philosophy maximizes flexibility while maintaining structural strength, enabling easy installation around obstacles and through confined spaces commonly encountered in bathroom and toilet environments. The carefully engineered plating process enhances the natural corrosion resistance of the stainless steel substrate, creating a protective barrier that extends operational lifespan significantly beyond conventional alternatives.

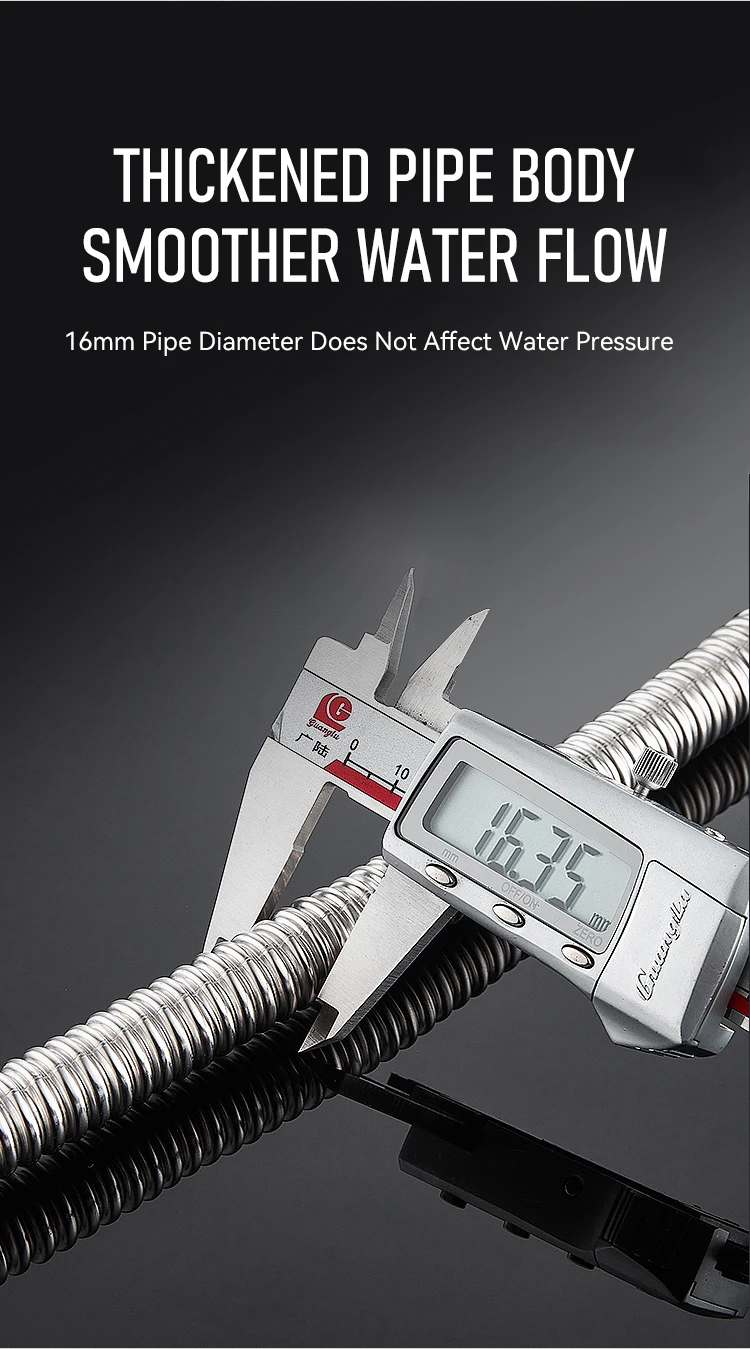

The innovative manufacturing process ensures consistent wall thickness throughout the entire length of the hose, promoting uniform pressure distribution and eliminating weak points that could compromise system integrity. This meticulous attention to detail results in a product that performs reliably across diverse temperature ranges and pressure conditions typical of residential and commercial water heating systems. The sophisticated surface treatment not only enhances aesthetic appeal but also provides additional protection against chemical exposure and environmental factors that could otherwise accelerate deterioration.

Features & Benefits

Superior Material Composition

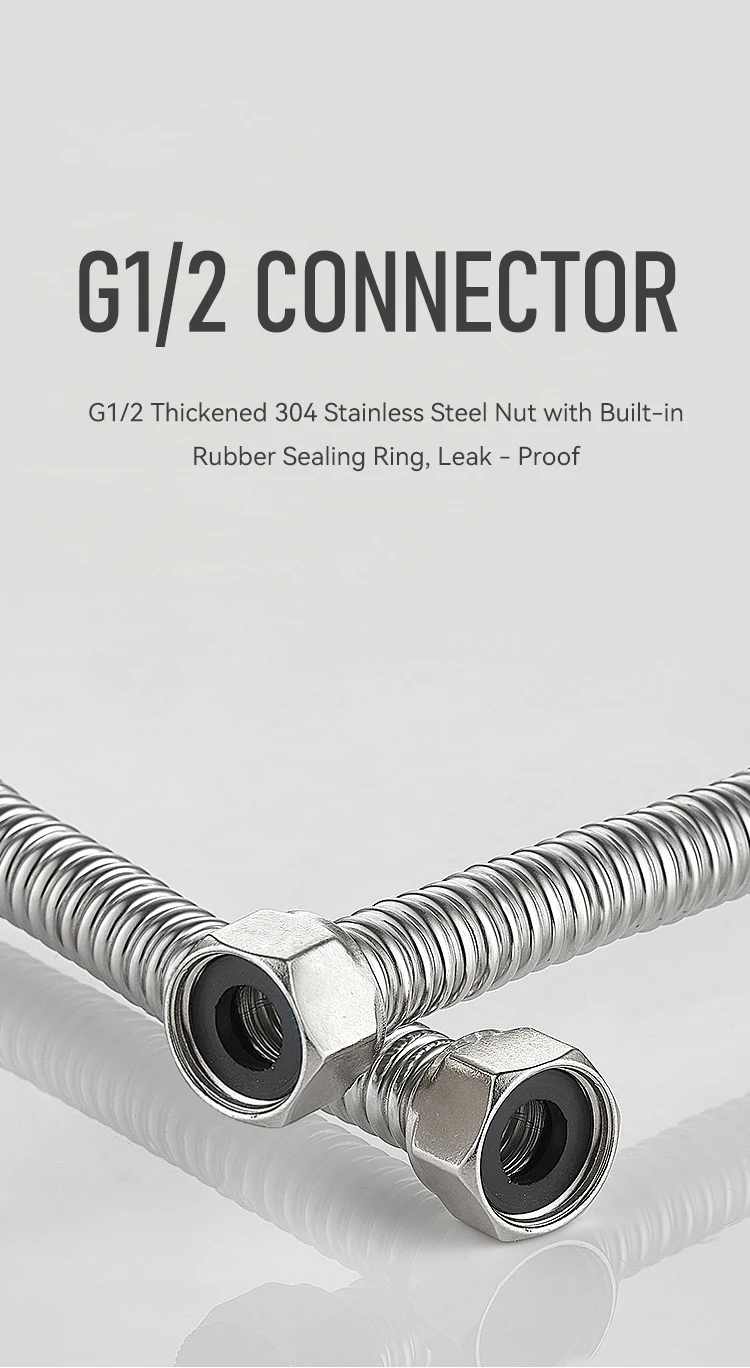

The foundation of this water heater hose excellence lies in its carefully selected stainless steel composition, which provides exceptional resistance to corrosion, chemical attack, and thermal stress. This material choice ensures compatibility with various water treatment chemicals and maintains structural integrity even when exposed to aggressive cleaning agents commonly used in bathroom and toilet maintenance. The inherent antimicrobial properties of stainless steel contribute to maintaining water quality by preventing bacterial growth within the hose interior.

The specialized plating treatment enhances the natural properties of the stainless steel substrate, creating multiple layers of protection against environmental factors that could compromise performance. This advanced surface treatment maintains its protective qualities throughout extended operational periods, ensuring consistent performance and reducing the need for frequent replacement or maintenance interventions that can disrupt facility operations.

Enhanced Flexibility and Durability

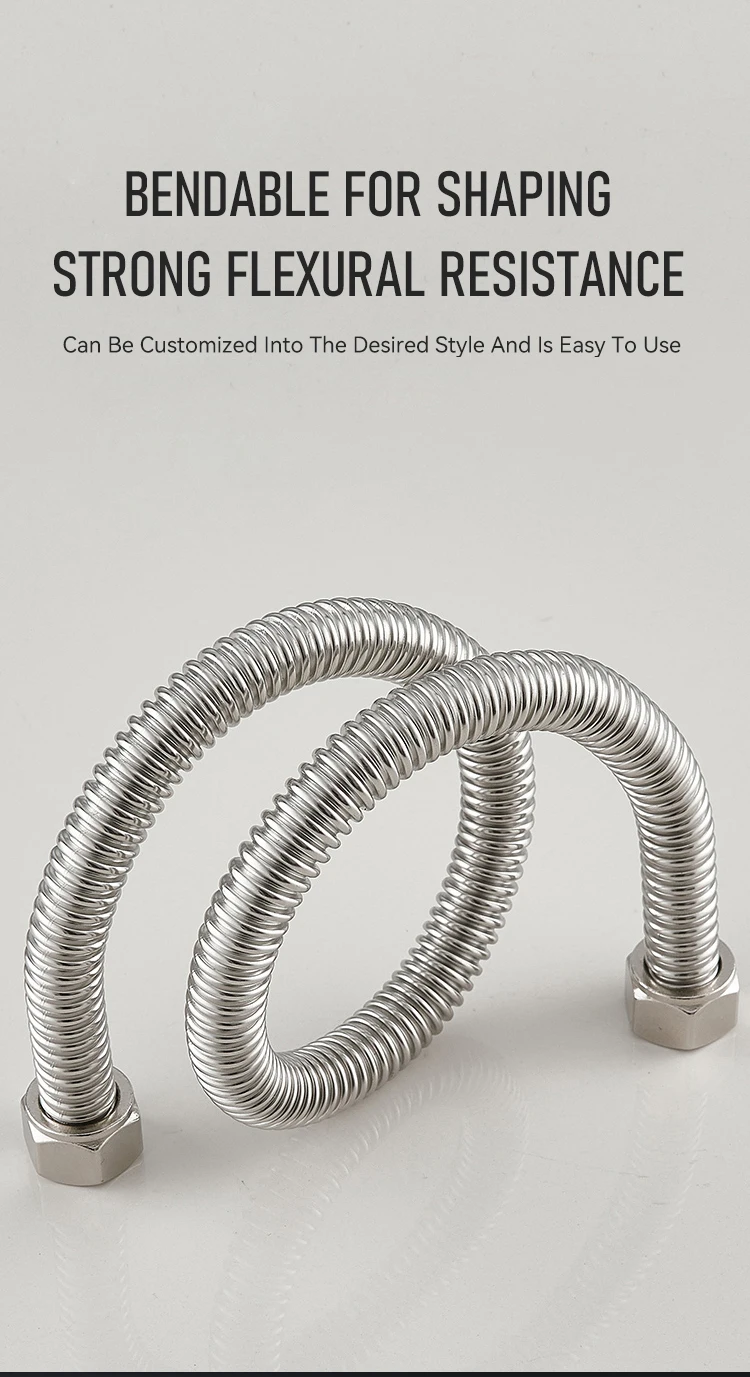

The corrugated design represents a sophisticated engineering solution that maximizes flexibility while preserving structural strength essential for reliable long-term performance. This innovative configuration allows the hose to bend and flex repeatedly without developing stress fractures or fatigue failures that commonly affect rigid piping systems. The enhanced flexibility simplifies installation procedures, reducing labor costs and enabling efficient routing through complex architectural configurations.

The durability characteristics of this Corrugated Plated 304 Stainless Steel Water Heater Hose Flexible Corrosion & Chemical Resistant for Bathroom Toilet extend far beyond basic functional requirements, incorporating design elements that resist mechanical damage from external impacts and vibration-induced wear. The robust construction maintains dimensional stability under varying pressure conditions, ensuring consistent flow characteristics throughout the operational lifespan.

Chemical and Corrosion Resistance

The comprehensive chemical resistance profile of this water heater hose accommodates exposure to various cleaning chemicals, water treatment additives, and environmental contaminants without experiencing degradation or performance compromise. This resistance extends to chlorine-based disinfectants, alkaline cleaners, and acidic descaling solutions commonly encountered in bathroom and toilet maintenance protocols. The protective plating maintains its barrier properties even under prolonged chemical exposure, ensuring reliable protection of the underlying stainless steel structure.

Corrosion resistance represents a fundamental advantage that translates directly into extended operational lifespan and reduced maintenance requirements. The multi-layered protection system prevents the formation of corrosion products that could contaminate water supplies or create flow restrictions within the hose interior. This comprehensive protection maintains system efficiency and water quality standards throughout extended service periods.

Applications & Use Cases

The versatility of this advanced water heater hose extends across numerous residential and commercial applications where reliable water supply connectivity is essential. In bathroom installations, the hose provides flexible connections between water heaters and fixture supply lines, accommodating building settling and thermal expansion without compromising system integrity. The enhanced flexibility enables efficient routing around structural elements, reducing installation complexity and minimizing the need for additional fittings that could create potential failure points.

Commercial toilet facilities benefit significantly from the chemical resistance properties when exposed to industrial-strength cleaning protocols and water treatment systems. The robust construction withstands the demanding operational conditions of high-traffic facilities while maintaining consistent performance standards. Healthcare facilities, educational institutions, and hospitality venues rely on this type of reliable plumbing infrastructure to ensure uninterrupted water supply and minimize maintenance disruptions that could affect daily operations.

Industrial applications where water heating systems must operate in challenging environments find this Corrugated Plated 304 Stainless Steel Water Heater Hose Flexible Corrosion & Chemical Resistant for Bathroom Toilet particularly valuable due to its resistance to environmental contaminants and ability to maintain performance under varying operational conditions. Manufacturing facilities, processing plants, and commercial kitchens benefit from the enhanced durability and chemical resistance when connecting water heating equipment in areas where traditional piping materials might experience accelerated deterioration.

Quality Control & Compliance

Rigorous quality control protocols ensure every water heater hose meets stringent performance standards before reaching end users. Comprehensive testing procedures evaluate pressure resistance, flexibility retention, and corrosion resistance under accelerated aging conditions that simulate years of operational exposure. Advanced inspection techniques verify consistent wall thickness, surface quality, and dimensional accuracy throughout the manufacturing process, ensuring reliable performance across all production batches.

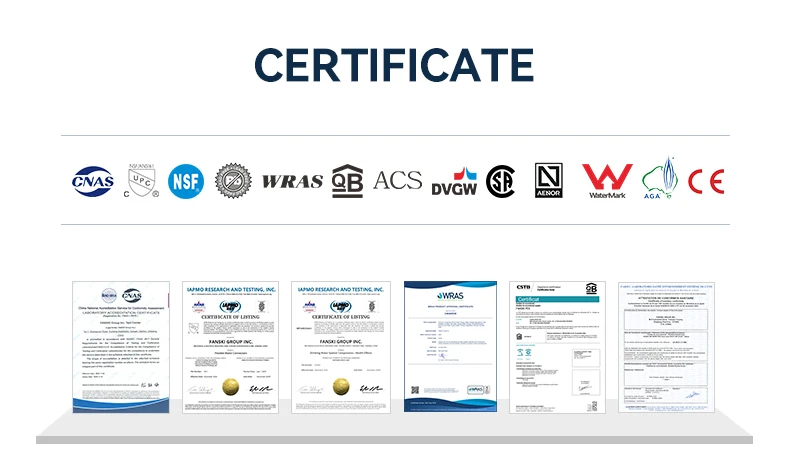

Compliance with international plumbing standards and safety regulations forms an integral part of the manufacturing process, ensuring compatibility with global building codes and installation practices. Environmental compliance initiatives address material sourcing, manufacturing processes, and end-of-life recyclability considerations that align with sustainable construction practices. These comprehensive compliance measures provide confidence for contractors, architects, and facility managers when specifying plumbing components for critical applications.

Advanced metallurgical testing confirms the chemical composition and mechanical properties of the stainless steel substrate, while specialized coating analysis verifies the integrity and performance characteristics of the protective plating system. These detailed quality assurance procedures ensure consistent product performance and reliability that meets the demanding requirements of professional plumbing installations.

Customization & Branding Options

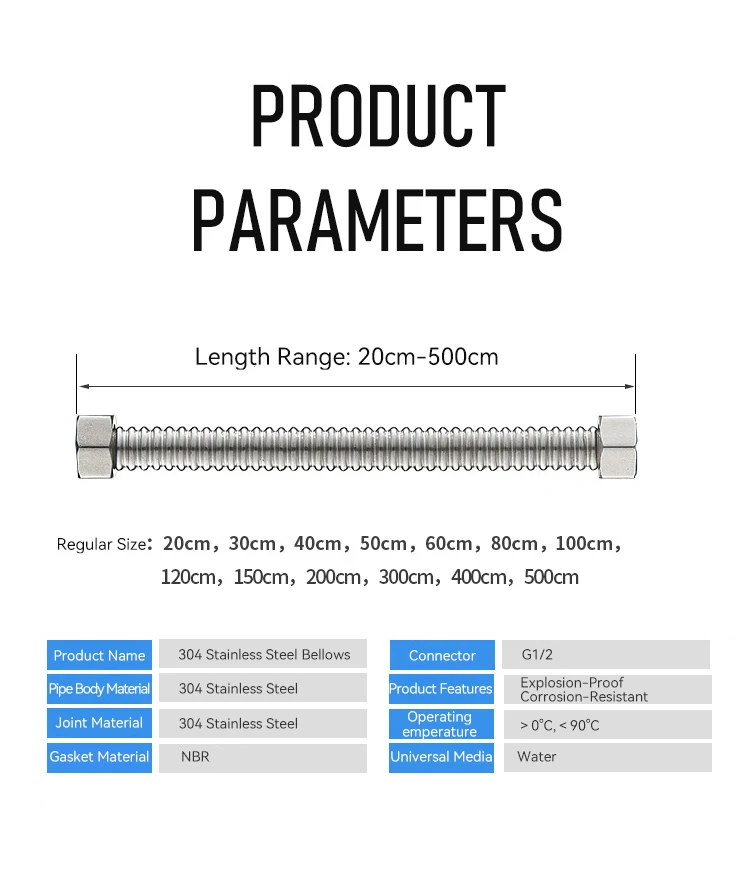

Professional installation environments often require customized solutions that address specific dimensional requirements, connection configurations, or performance parameters. The manufacturing flexibility inherent in the production process accommodates custom length specifications, specialized end fittings, and modified surface treatments that meet unique application requirements. These customization capabilities enable optimal integration with existing plumbing systems while maintaining the superior performance characteristics of the standard product configuration.

Private labeling and branding opportunities allow distributors and contractors to offer differentiated products that reflect their commitment to quality and customer service. Custom packaging solutions and product identification systems can incorporate company logos, technical specifications, and installation guidelines that enhance professional image and customer confidence. These branding options support market positioning strategies while maintaining the exceptional quality and performance that defines this advanced water heater hose solution.

Engineering support services assist customers in developing application-specific configurations that optimize performance for unique installation requirements. Technical consultation addresses compatibility considerations, installation recommendations, and maintenance protocols that maximize operational lifespan and system reliability. This comprehensive support approach ensures successful implementation across diverse applications and operational environments.

Packaging & Logistics Support

Professional packaging solutions protect product integrity throughout the distribution chain while facilitating efficient handling and storage procedures. Protective packaging materials prevent surface damage and contamination during transportation, ensuring products reach installation sites in optimal condition. Standardized packaging dimensions optimize shipping efficiency and warehouse storage utilization, reducing distribution costs and environmental impact associated with transportation activities.

Comprehensive logistics support encompasses inventory management solutions, delivery scheduling coordination, and technical documentation that streamlines the procurement process for contractors and distributors. Flexible shipping options accommodate project timelines and budget constraints while maintaining product quality and delivery reliability. Advanced tracking systems provide real-time visibility into order status and delivery progress, enabling proactive project management and scheduling optimization.

International shipping capabilities ensure global availability of this premium water heater hose solution, supporting infrastructure development projects and facility upgrade initiatives worldwide. Specialized export packaging and documentation services facilitate customs clearance and regulatory compliance across diverse international markets. These comprehensive logistics capabilities support global supply chain requirements while maintaining the quality standards and service excellence that characterize professional plumbing supply operations.

Why Choose Us

Our extensive experience in manufacturing precision plumbing components for international markets has established a reputation for quality excellence and technical innovation that spans multiple decades of successful global collaboration. This deep understanding of diverse market requirements and regulatory environments enables us to deliver solutions that consistently exceed performance expectations while meeting the specific needs of regional installation practices and building standards.

As a recognized metal packaging manufacturer and custom tin box supplier serving various industries, our manufacturing capabilities extend beyond traditional plumbing components to encompass comprehensive OEM tin packaging solutions and specialized metal packaging supplier services. This diverse expertise in metal fabrication and surface treatment technologies directly benefits our plumbing product development, incorporating advanced materials science and precision manufacturing techniques that enhance product performance and reliability.

The commitment to sustainable manufacturing practices and environmental responsibility guides our production processes and material sourcing decisions, ensuring compatibility with green building initiatives and corporate sustainability goals. Advanced quality management systems and continuous improvement programs maintain consistent product excellence while adapting to evolving market requirements and technological advancements that define the future of plumbing infrastructure.

Technical support services and engineering consultation capabilities provide comprehensive assistance throughout the specification, installation, and maintenance phases of project implementation. This holistic approach to customer support ensures optimal product performance and customer satisfaction while building long-term partnerships that support ongoing business success and market development initiatives.

Conclusion

The Corrugated Plated 304 Stainless Steel Water Heater Hose Flexible Corrosion & Chemical Resistant for Bathroom Toilet represents a sophisticated engineering solution that addresses the complex requirements of modern plumbing systems through superior material composition, innovative design, and comprehensive quality assurance. The combination of enhanced flexibility, exceptional corrosion resistance, and robust construction creates a reliable foundation for water heating systems that must perform consistently under demanding operational conditions. This advanced hose solution delivers measurable value through extended operational lifespan, reduced maintenance requirements, and reliable performance that supports critical infrastructure operations across residential, commercial, and industrial applications. The comprehensive approach to quality, customization, and customer support ensures successful implementation and long-term satisfaction for contractors, facility managers, and end users who depend on reliable plumbing infrastructure for their daily operations.