Introduction

In today's demanding industrial landscape, reliable fluid transfer solutions are essential for maintaining operational efficiency and safety across diverse applications. The PPW Manufactory Supply 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable represents a breakthrough in flexible piping technology, engineered to meet the rigorous demands of modern industrial processes. This innovative corrugated hose combines the superior corrosion resistance of premium stainless steel with exceptional flexibility, making it an ideal choice for applications requiring both durability and adaptability. Whether handling high-temperature fluids, aggressive chemicals, or demanding pressure conditions, this flexible metal pipe delivers consistent performance while maintaining structural integrity throughout its service life.

The sophisticated design of this corrugated hose addresses critical challenges faced by engineers and facility managers worldwide. Traditional rigid piping systems often struggle with thermal expansion, vibration dampening, and installation constraints in tight spaces. Our flexible metal pipe solution overcomes these limitations through its advanced corrugated construction, which provides exceptional flexibility without compromising flow characteristics or pressure ratings. This makes it particularly valuable for applications where conventional piping systems would require complex routing or frequent maintenance interventions.

Product Overview

The PPW Manufactory Supply corrugated hose features a sophisticated construction utilizing high-grade stainless steel that ensures optimal performance across a wide range of operating conditions. The corrugated design incorporates precisely engineered convolutions that provide exceptional flexibility while maintaining structural strength and pressure resistance. This unique configuration allows the hose to bend, twist, and flex without kinking or restricting flow, making it ideal for dynamic applications where movement is required.

The stainless steel construction offers outstanding resistance to corrosion, oxidation, and chemical attack, ensuring long-term reliability even in harsh environments. The material's inherent properties make it suitable for handling various media including gases, liquids, and steam across different temperature ranges. The smooth interior surface promotes efficient flow characteristics while minimizing pressure drop, contributing to overall system efficiency and energy savings.

This flexible metal pipe incorporates advanced manufacturing techniques that ensure consistent quality and dimensional accuracy throughout its length. The corrugated profile is formed using precision tooling that creates uniform convolutions, providing predictable flexibility characteristics and pressure ratings. The seamless construction eliminates potential weak points that could compromise system integrity or create maintenance issues over time.

Features & Benefits

Superior Material Properties

The premium stainless steel construction of this corrugated hose delivers exceptional resistance to high temperatures, making it suitable for applications involving steam, hot gases, and heated liquids. The material maintains its mechanical properties across extreme temperature ranges, ensuring consistent performance without degradation or failure. This temperature resistance capability extends the service life of the hose while reducing maintenance requirements and system downtime.

Corrosion resistance is another key advantage of the stainless steel construction. The material's passive oxide layer provides natural protection against various corrosive agents, including acids, alkalis, and chlorides. This resistance ensures that the PPW Manufactory Supply 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable maintains its integrity even when exposed to aggressive chemicals or corrosive environments commonly found in industrial processes.

Exceptional Flexibility and Durability

The corrugated design provides remarkable flexibility that allows the hose to accommodate thermal expansion, vibration, and movement without stress concentration or fatigue failure. This flexibility is particularly valuable in applications where equipment movement occurs during operation or where thermal cycling creates dimensional changes in connected components. The ability to absorb these movements prevents stress transfer to connected equipment and piping systems.

Durability is enhanced through the robust construction that resists mechanical damage, abrasion, and external impact. The corrugated profile distributes stress evenly across the hose length, preventing localized failures that could compromise system operation. This durability translates to extended service intervals and reduced replacement costs, providing significant economic benefits over the product's lifecycle.

Optimal Flow Characteristics

Despite its corrugated exterior, the hose maintains smooth interior surfaces that promote efficient fluid flow and minimize pressure losses. The design optimization ensures that flexibility does not come at the expense of hydraulic performance, making it suitable for applications where flow efficiency is critical. This characteristic is particularly important in systems where energy costs are a consideration or where precise flow control is required.

Applications & Use Cases

The versatility of this flexible metal pipe makes it suitable for numerous industrial applications across diverse sectors. In chemical processing facilities, the hose excels in handling aggressive chemicals, solvents, and process fluids that would quickly degrade conventional flexible connections. The stainless steel construction provides compatibility with a wide range of chemical media while maintaining system integrity under demanding operating conditions.

Power generation facilities benefit from the hose's ability to handle high-temperature steam and condensate systems. The flexibility allows for thermal expansion accommodation in steam lines, turbine connections, and heat exchanger installations. The temperature resistance ensures reliable operation in these critical applications where failure could result in significant downtime and safety concerns.

Food and beverage processing operations utilize this PPW Manufactory Supply 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable for sanitary applications where cleanliness and corrosion resistance are paramount. The smooth interior surfaces facilitate cleaning and sterilization procedures while the stainless steel construction meets hygiene standards required in food production environments.

HVAC systems incorporate these flexible connections for handling refrigerants, heating fluids, and ventilation gases. The flexibility accommodates equipment vibration and thermal movement while maintaining leak-tight connections. The durability ensures long-term reliability in building mechanical systems where access for maintenance may be limited.

Marine and offshore applications benefit from the corrosion resistance when handling seawater, brine, and other corrosive marine fluids. The flexible design accommodates vessel movement and vibration while maintaining system integrity in harsh marine environments. The robust construction withstands the demanding conditions encountered in offshore installations.

Quality Control & Compliance

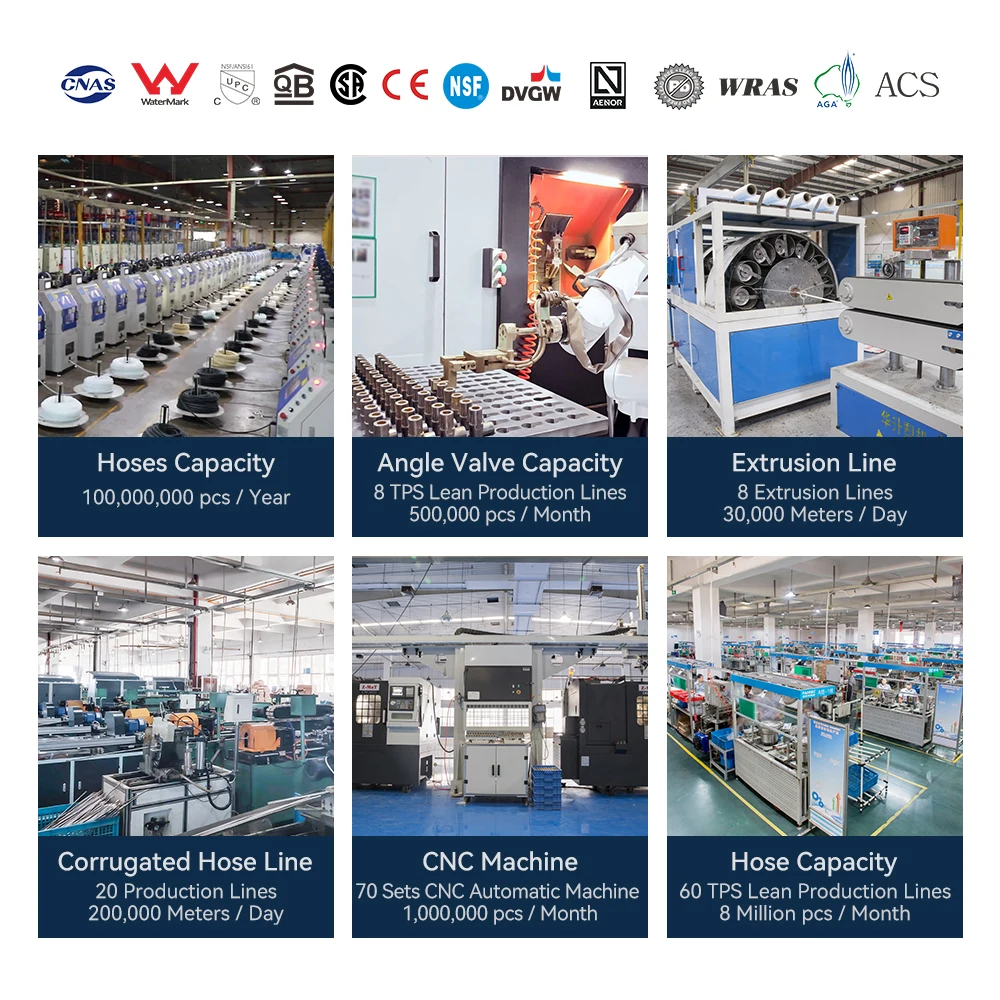

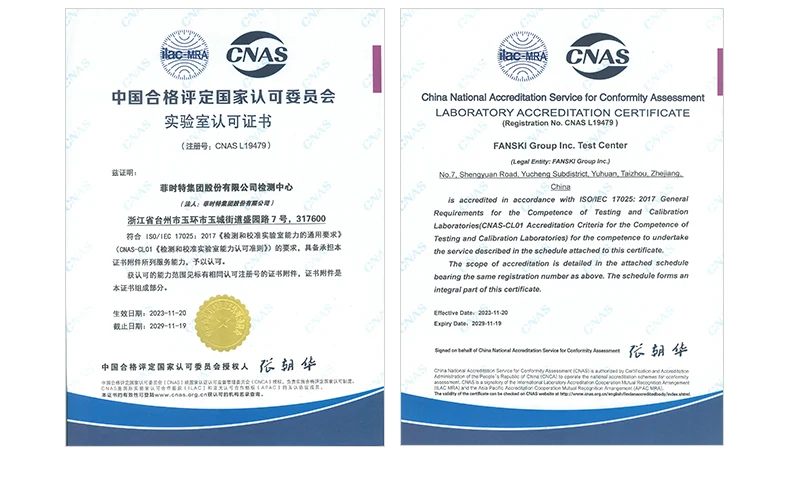

Manufacturing excellence is maintained through comprehensive quality control procedures that ensure each hose meets stringent performance standards. Advanced testing protocols verify material properties, dimensional accuracy, and pressure ratings before products leave the facility. These quality measures provide confidence in product performance and reliability across demanding applications.

Material traceability systems track the origin and properties of raw materials used in production, ensuring consistency and quality throughout the manufacturing process. This traceability enables rapid identification and resolution of any quality concerns while maintaining detailed records for compliance documentation. The systematic approach to quality management supports continuous improvement initiatives and customer satisfaction.

International standards compliance ensures that the flexible metal pipe meets or exceeds recognized industry specifications for materials, construction, and performance. This compliance facilitates global market acceptance and provides assurance to engineers and specifiers regarding product suitability for their applications. Regular audits and certifications maintain compliance status and demonstrate ongoing commitment to quality excellence.

Environmental considerations are integrated into the manufacturing process to minimize environmental impact while maintaining product quality. Sustainable practices include material recycling, energy-efficient production methods, and waste reduction initiatives. These environmental stewardship efforts align with global sustainability goals while delivering high-performance products to customers worldwide.

Customization & Branding Options

Recognizing the diverse requirements of different applications, comprehensive customization services are available to tailor the corrugated hose to specific customer needs. Length customization allows for precise fitting to installation requirements, eliminating the need for field modifications or additional connections that could compromise system integrity. This precision manufacturing approach reduces installation time and improves overall system reliability.

End fitting options accommodate various connection methods and standards used across different industries and regions. Standard threaded connections, flanged ends, and specialized coupling designs can be incorporated to ensure compatibility with existing equipment and piping systems. This flexibility in end fitting selection simplifies system integration and reduces the need for additional adapters or transition pieces.

Custom metal packaging solutions are available for OEMs and distributors requiring specialized packaging for their market channels. These packaging options can incorporate branding elements, product information, and protection features tailored to specific distribution requirements. As an experienced metal packaging supplier, we understand the importance of presentation and protection in global markets.

Private labeling services support distributors and resellers in developing their brand presence in local markets. Custom labeling, documentation, and packaging options help establish brand identity while maintaining product quality and performance standards. This support enables partners to build their market presence with confidence in product reliability and performance.

Packaging & Logistics Support

Professional packaging systems protect the corrugated hose during transportation and storage while facilitating efficient handling and installation. Protective packaging prevents damage from external impacts, contamination, and environmental exposure during shipping. The packaging design considers the flexible nature of the product while providing adequate protection for global distribution requirements.

Efficient logistics support includes documentation services that facilitate international shipping and customs clearance procedures. Comprehensive product documentation, certificates of compliance, and material test reports are provided to support global distribution and installation requirements. This documentation support reduces delays and complications in international transactions.

Inventory management services help distributors optimize their stock levels while ensuring product availability for customer requirements. Flexible ordering systems accommodate varying demand patterns while maintaining efficient inventory turnover. This support enables partners to provide responsive customer service while managing working capital effectively.

Technical support services extend beyond product delivery to include installation guidance, application assistance, and troubleshooting support. This comprehensive service approach ensures successful product implementation and customer satisfaction throughout the product lifecycle. The technical support team brings extensive experience in flexible piping applications across diverse industries.

Why Choose Us

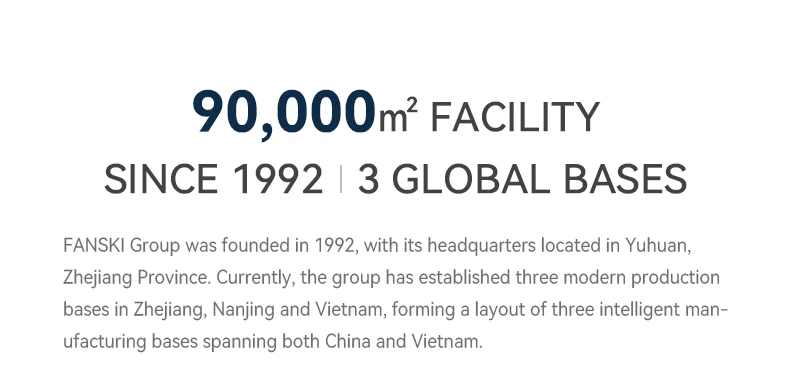

With extensive experience serving global markets across multiple continents, our company has established a reputation for delivering high-quality flexible piping solutions that meet the demanding requirements of modern industrial applications. This international market presence provides deep understanding of diverse application requirements and regulatory standards that influence product design and manufacturing processes.

Our role as a trusted metal packaging manufacturer extends beyond individual products to encompass comprehensive solutions that address complex system requirements. This broader perspective enables us to provide valuable application guidance and system optimization recommendations that enhance overall project success. The multi-industry expertise developed through serving diverse market segments brings unique insights to each customer interaction.

Innovation leadership drives continuous product development and improvement initiatives that keep our solutions at the forefront of industry advancement. Investment in research and development ensures that products like the PPW Manufactory Supply 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable incorporate the latest materials science and manufacturing techniques. This commitment to innovation provides customers with access to cutting-edge solutions that address emerging application challenges.

Global collaboration with leading engineering firms, contractors, and end users provides valuable feedback that influences product development and quality improvement efforts. These partnerships enable us to understand real-world application challenges and develop solutions that deliver superior performance and reliability. The collaborative approach ensures that products meet actual market needs rather than theoretical requirements.

As an established custom tin box supplier and OEM tin packaging solutions provider, our diversified manufacturing capabilities enable efficient production and consistent quality across product lines. This manufacturing expertise translates to reliable delivery schedules and consistent product quality that customers can depend upon for their critical applications.

Conclusion

The PPW Manufactory Supply 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable represents an exceptional solution for demanding industrial applications requiring reliable, flexible piping connections. Its combination of superior material properties, innovative corrugated design, and proven performance characteristics makes it an ideal choice for applications across chemical processing, power generation, food and beverage, HVAC, and marine industries. The comprehensive quality control procedures, customization options, and professional support services ensure that customers receive solutions tailored to their specific requirements while maintaining the highest standards of performance and reliability. This flexible metal pipe delivers outstanding value through its extended service life, reduced maintenance requirements, and superior performance characteristics that contribute to overall system efficiency and operational success.