Introduction

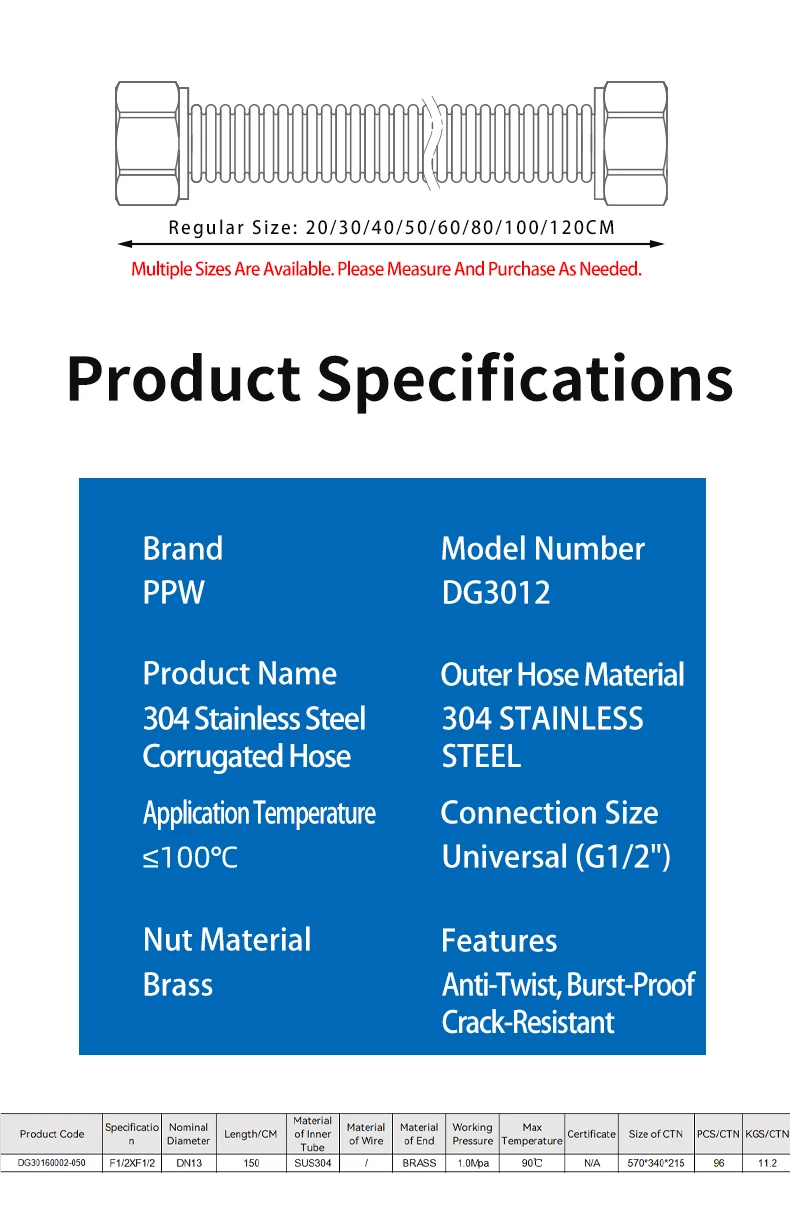

In today's demanding industrial landscape, reliable fluid transfer solutions are essential for maintaining operational efficiency and safety standards. The 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable represents a pinnacle of engineering excellence, designed to meet the rigorous requirements of modern industrial applications. This premium flexible metal piping solution combines superior corrosion resistance with exceptional durability, making it an indispensable component for professionals across diverse industries including petrochemical, food processing, pharmaceutical, and HVAC systems.

Manufacturing facilities worldwide increasingly demand piping solutions that can withstand extreme operating conditions while maintaining structural integrity over extended service periods. This corrugated stainless steel hose addresses these challenges through its innovative design and superior material composition, delivering reliable performance in applications requiring flexibility, temperature resistance, and chemical compatibility.

Product Overview

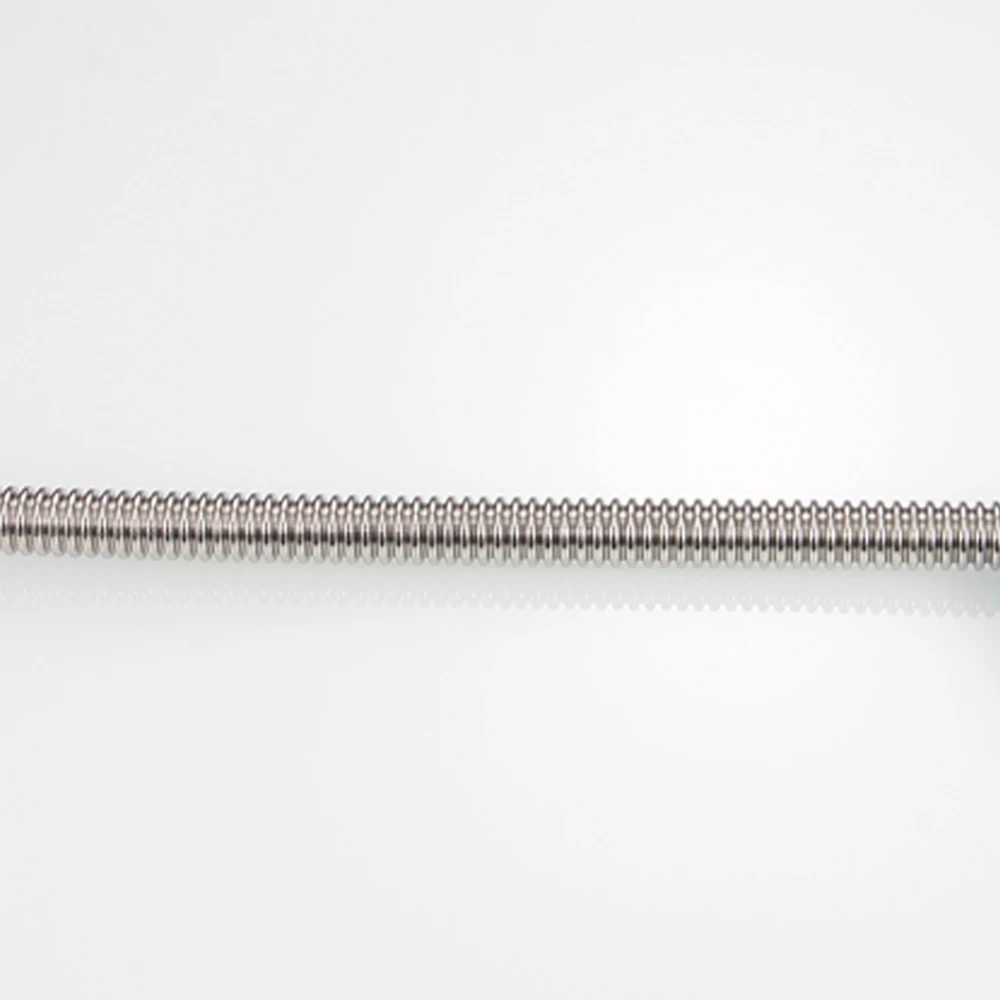

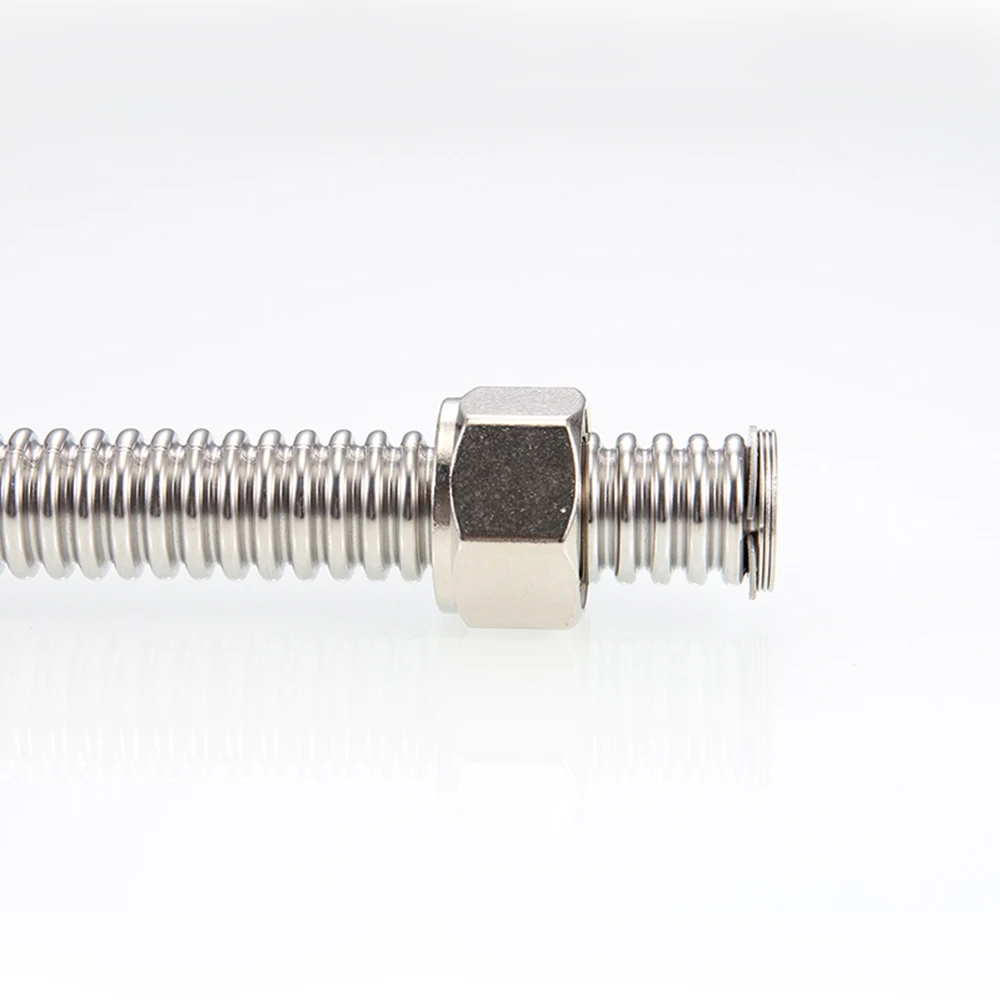

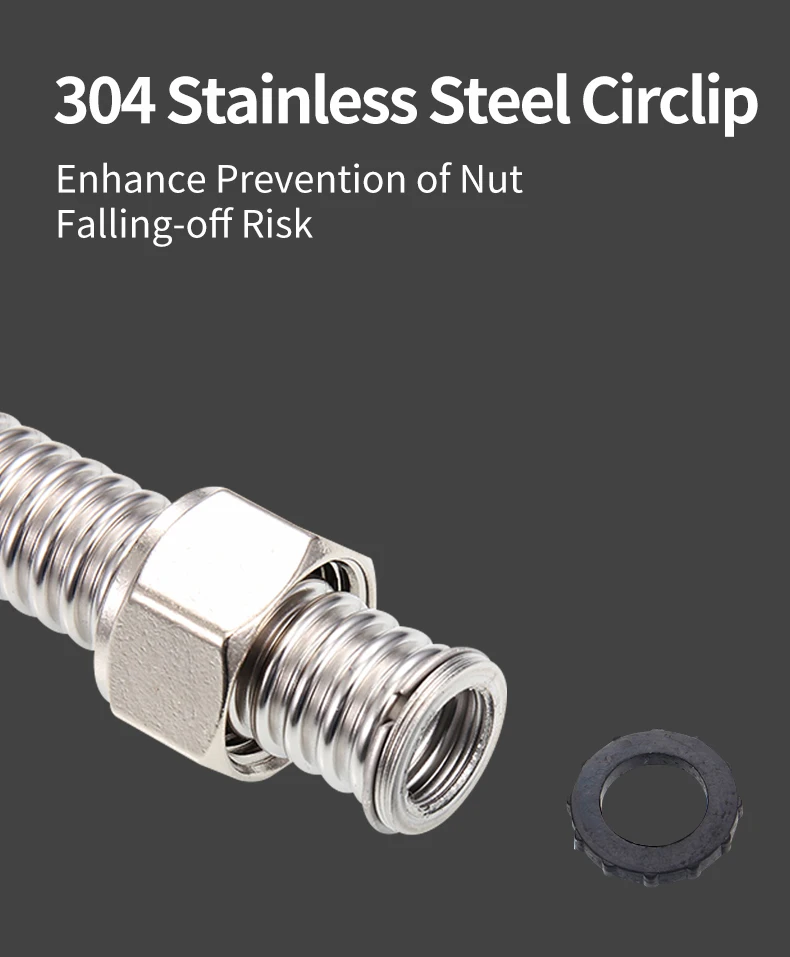

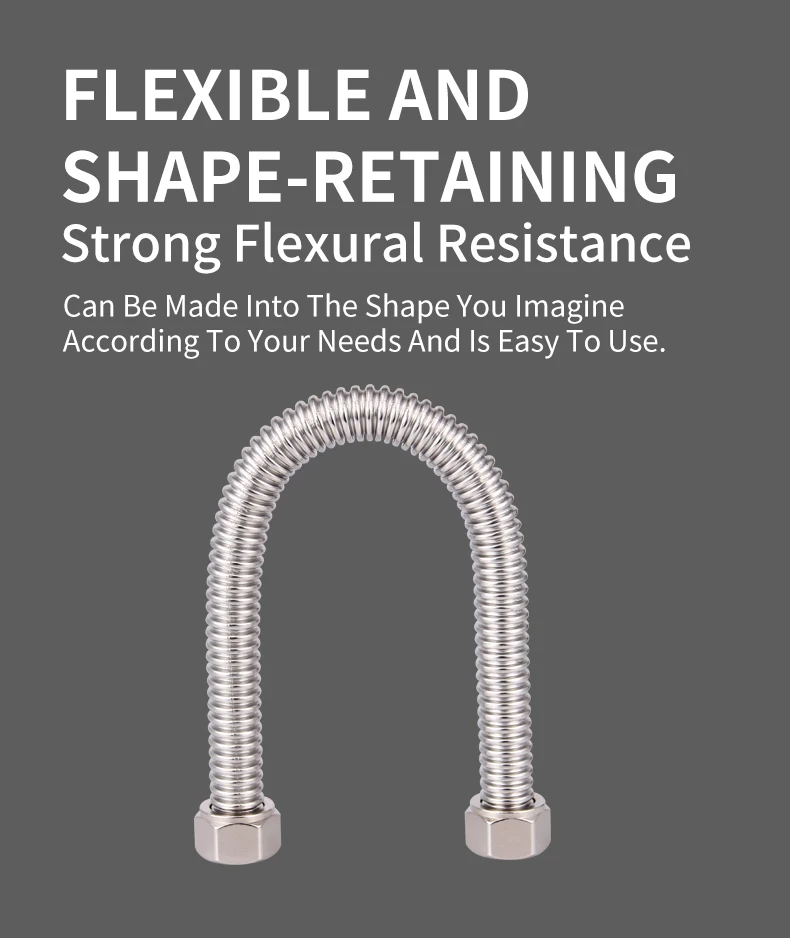

This premium flexible metal pipe represents a sophisticated engineering solution crafted from high-grade stainless steel material. The corrugated design enhances flexibility while maintaining pressure resistance, allowing for optimal performance in dynamic installations where traditional rigid piping systems prove inadequate. The bellows-style construction enables smooth fluid flow while accommodating thermal expansion, vibration absorption, and angular displacement requirements common in industrial environments.

The stainless steel construction ensures exceptional resistance to oxidation, chemical attack, and environmental degradation, making this 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable suitable for both aggressive chemical applications and high-purity processes. The smooth interior surface minimizes pressure drop and reduces the risk of contamination, while the external corrugated profile provides enhanced flexibility without compromising structural strength.

Advanced manufacturing techniques ensure consistent wall thickness and optimal corrugation geometry, resulting in superior fatigue resistance and extended service life. The precision-formed corrugations distribute stress evenly across the hose structure, preventing localized failure points that commonly affect inferior alternatives. This engineering approach delivers reliable performance across temperature extremes and demanding operational cycles.

Features & Benefits

Superior Material Properties

The austenitic stainless steel construction provides exceptional corrosion resistance across a wide range of chemical environments, ensuring reliable performance in applications involving acids, alkalis, and aggressive industrial fluids. This material composition maintains mechanical properties across extreme temperature ranges, from cryogenic applications to high-temperature steam systems, making it versatile for diverse industrial requirements.

The inherent strength-to-weight ratio of stainless steel construction reduces installation complexity while providing superior pressure handling capabilities compared to alternative materials. The non-magnetic properties of the austenitic structure ensure compatibility with sensitive electronic environments and magnetic resonance applications.

Enhanced Flexibility and Movement Accommodation

The corrugated design enables multi-directional movement accommodation, including axial compression, extension, lateral displacement, and angular deflection. This flexibility eliminates the need for complex piping arrangements and reduces stress on connected equipment, extending system life and reducing maintenance requirements. The smooth radius bends prevent flow turbulence and minimize pressure losses, optimizing system efficiency.

Vibration dampening characteristics inherent in the flexible design protect sensitive equipment from mechanical stress and reduce noise transmission throughout connected systems. This feature proves particularly valuable in precision manufacturing environments and occupied building spaces where noise control is essential.

Temperature and Pressure Performance

Exceptional thermal stability enables reliable operation across extreme temperature ranges without degradation of mechanical properties or sealing performance. The 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable maintains structural integrity under thermal cycling conditions that would compromise alternative materials, ensuring consistent performance throughout varying operational demands.

Robust pressure handling capabilities accommodate both positive and negative pressure applications, making this solution suitable for vacuum systems as well as high-pressure installations. The uniform corrugation geometry distributes stress evenly, preventing localized weakening and ensuring reliable containment under demanding pressure conditions.

Applications & Use Cases

Industrial steam systems benefit significantly from the thermal expansion accommodation and temperature resistance provided by this flexible metal piping solution. Power generation facilities utilize these hoses for turbine connections, boiler applications, and cooling system installations where thermal cycling and vibration management are critical factors. The corrosion resistance ensures reliable performance in steam condensate handling and feedwater applications.

Chemical processing industries depend on this corrugated hose for aggressive fluid handling applications where traditional materials fail prematurely. The chemical inertness of stainless steel construction prevents contamination of process streams while maintaining system integrity under corrosive conditions. Pharmaceutical manufacturing facilities utilize these hoses for clean steam applications, process fluid transfer, and sanitary piping systems requiring frequent cleaning and sterilization.

HVAC and building automation systems incorporate these flexible metal pipes for equipment connections, thermal expansion joints, and vibration isolation applications. The flexibility enables simplified installation in congested mechanical spaces while providing reliable performance throughout seasonal temperature variations. Food processing facilities depend on the sanitary properties and easy cleaning characteristics for ingredient handling, processing equipment connections, and clean-in-place systems.

Petrochemical refineries utilize this 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable for hydrocarbon service applications where fire resistance and chemical compatibility are paramount. The ability to handle both liquid and gaseous media makes these hoses versatile for diverse refinery applications including catalyst handling, process gas transfer, and emergency relief systems.

Quality Control & Compliance

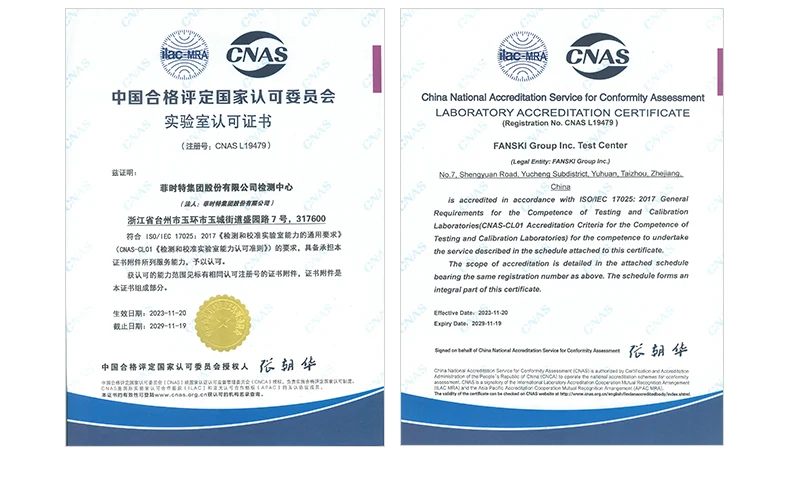

Rigorous manufacturing standards ensure consistent product quality and reliable performance across diverse applications. Each hose undergoes comprehensive testing protocols including pressure testing, leak detection, and dimensional verification to guarantee conformance with international standards and customer specifications. Advanced metallurgical analysis confirms material composition and mechanical properties, ensuring optimal performance characteristics.

Quality management systems incorporate continuous improvement processes and statistical process control to maintain manufacturing excellence. Traceability documentation accompanies each product, providing complete material certification and manufacturing history for critical applications requiring detailed quality records. Regular audits and third-party inspections validate manufacturing processes and quality system effectiveness.

International certification compliance ensures global market acceptance and regulatory conformance across diverse industrial sectors. The manufacturing facility maintains certifications relevant to pressure vessel codes, sanitary standards, and environmental management systems. These certifications demonstrate commitment to quality excellence and provide customers confidence in product reliability and performance.

Customization & Branding Options

Comprehensive customization capabilities accommodate unique application requirements and customer specifications. Engineering support services work closely with customers to develop optimal solutions for challenging applications, considering factors such as installation constraints, operational parameters, and maintenance requirements. Custom end fitting configurations enable seamless integration with existing systems and equipment.

As an experienced metal packaging manufacturer with extensive industrial capabilities, our organization provides tailored solutions that meet specific operational demands. Custom braiding options enhance pressure ratings and provide additional protection in demanding environments. Specialized coatings and surface treatments can be applied to address specific environmental challenges or aesthetic requirements.

Private labeling services enable distributors and system integrators to maintain brand consistency throughout their product offerings. Custom packaging solutions protect products during shipping while reinforcing brand identity and professional presentation. Technical documentation and certification packages can be customized to meet specific customer requirements and regulatory compliance needs.

Packaging & Logistics Support

Professional packaging solutions protect product integrity during international shipping while optimizing logistics efficiency. Protective packaging materials prevent damage during handling and transportation, ensuring products arrive in optimal condition. Space-efficient packaging design reduces shipping costs while maintaining adequate protection for delicate corrugated structures.

Global logistics coordination facilitates efficient delivery to international destinations through established shipping networks and customs clearance procedures. Comprehensive documentation packages include all necessary shipping documents, material certifications, and customs declarations to expedite international transactions. Multiple shipping options accommodate various delivery requirements and budget considerations.

Inventory management services help customers optimize stock levels and ensure product availability for critical applications. Flexible packaging configurations accommodate both small quantity orders and large volume shipments efficiently. Specialized handling procedures ensure product integrity throughout the supply chain from manufacturing facility to final destination.

Why Choose Us

With decades of experience serving international markets, our organization has established a reputation for excellence in flexible metal piping solutions. Our global presence enables responsive customer support and reliable product availability across major industrial regions. Extensive industry knowledge allows us to provide technical guidance and application expertise that helps customers optimize their system designs and operational efficiency.

As a recognized custom tin box supplier and OEM tin packaging solutions provider, we bring diverse manufacturing expertise to every project. Our multi-industry experience enables innovative approaches to challenging applications and ensures comprehensive understanding of varied customer requirements. Continuous investment in manufacturing technology and quality improvement maintains our competitive advantage and ensures consistent product excellence.

Strong partnerships with leading industrial organizations worldwide demonstrate our commitment to customer success and long-term relationships. Our metal packaging supplier capabilities extend beyond basic product provision to include comprehensive engineering support, application analysis, and ongoing technical assistance. This holistic approach ensures optimal product selection and system performance throughout the product lifecycle.

Research and development initiatives keep our products at the forefront of technological advancement while maintaining proven reliability and performance standards. Collaborative relationships with customers drive innovation and enable development of next-generation solutions that address evolving industry challenges. Our commitment to sustainable manufacturing practices and environmental responsibility aligns with contemporary corporate values and regulatory requirements.

Conclusion

The 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable represents the optimal solution for demanding industrial applications requiring superior performance, reliability, and longevity. Its combination of advanced materials, precision engineering, and proven manufacturing excellence delivers exceptional value for critical fluid handling systems across diverse industries. The comprehensive range of features and benefits, coupled with extensive customization capabilities and professional support services, ensures optimal performance in virtually any application scenario. This flexible metal piping solution stands as a testament to engineering innovation and manufacturing excellence, providing customers with the confidence and reliability essential for successful industrial operations in today's competitive global marketplace.