Introduction

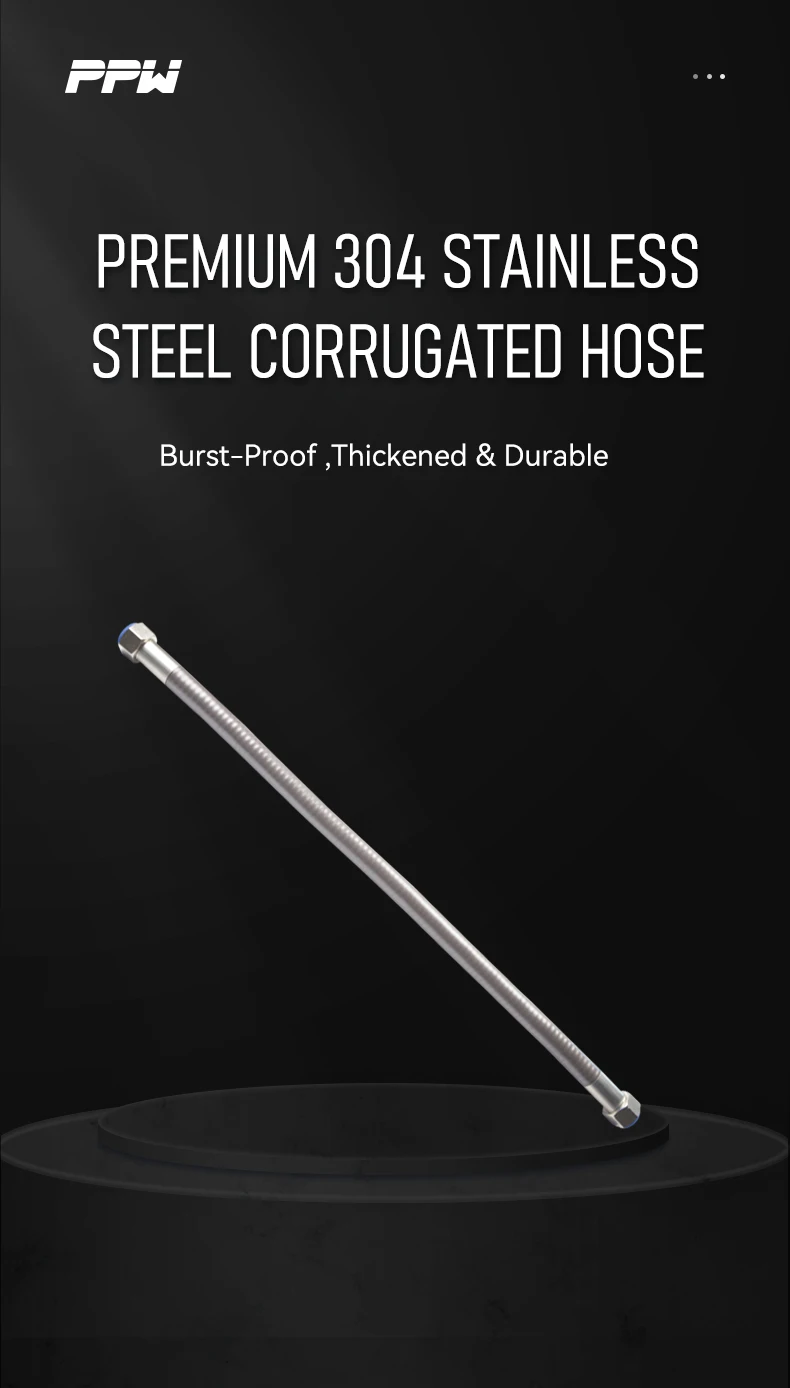

The 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water PVC-Coated Surface for Heat Insulation & Safe Handling represents the pinnacle of industrial fluid transfer technology. This premium flexible metal conduit combines the superior corrosion resistance of high-grade stainless steel with advanced PVC coating technology to deliver unmatched performance in demanding applications. Engineered for versatility and durability, this corrugated hose solution addresses the critical needs of modern industrial operations where reliable fluid transfer, thermal protection, and operator safety are paramount.

In today's competitive industrial landscape, businesses require flexible piping solutions that can withstand harsh operating conditions while maintaining consistent performance over extended service life. This innovative corrugated hose design bridges the gap between traditional rigid piping systems and conventional flexible hoses, offering the structural integrity of metal construction with the adaptability needed for complex installation scenarios.

Product Overview

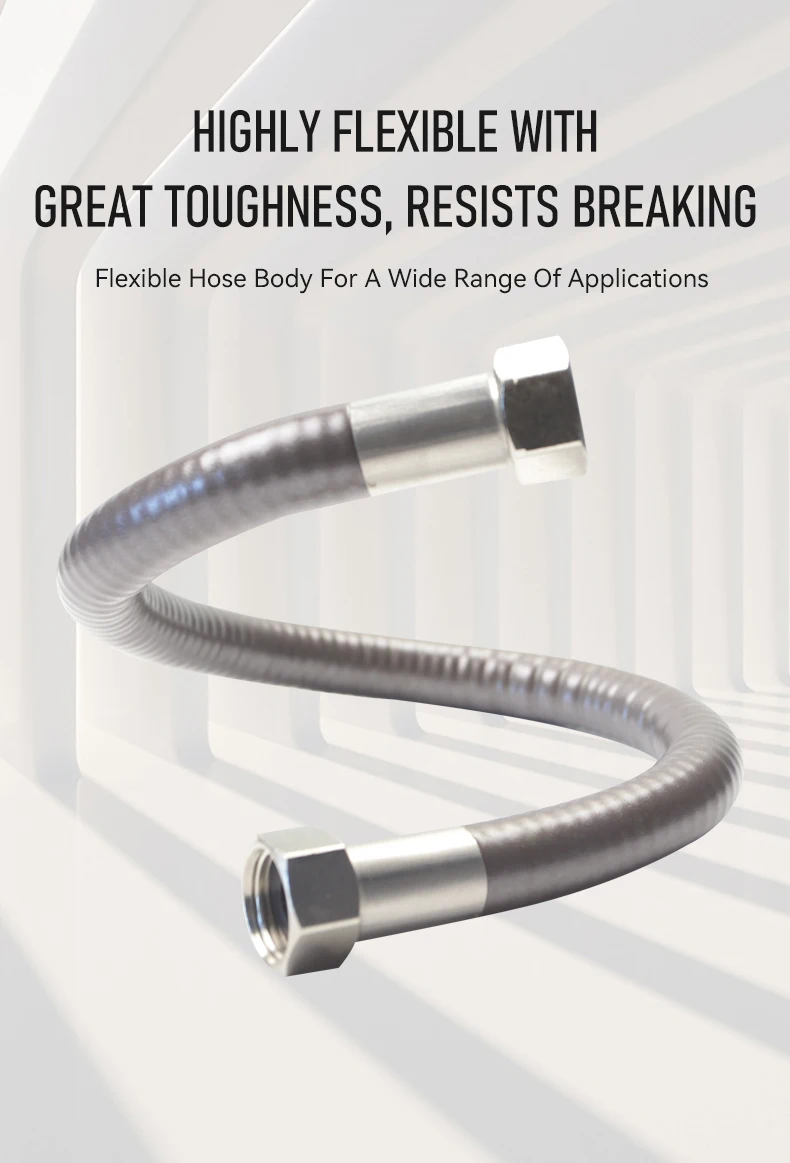

The 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water PVC-Coated Surface for Heat Insulation & Safe Handling features a sophisticated multi-layer construction that maximizes both functionality and safety. The core component utilizes premium-grade stainless steel formed into precise corrugated patterns that provide exceptional flexibility without compromising structural integrity. This corrugated design allows the hose to bend, twist, and flex while maintaining consistent flow characteristics and pressure ratings.

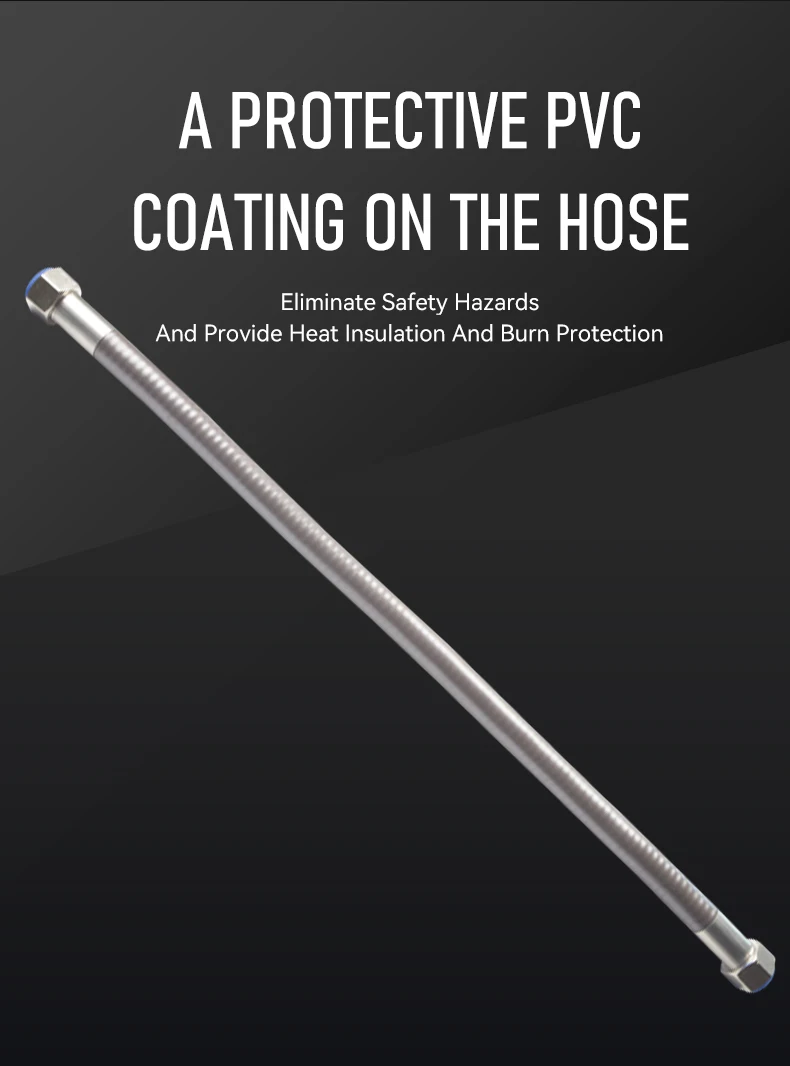

The specialized PVC coating applied to the exterior surface serves multiple critical functions beyond basic protection. This thermally insulating layer significantly reduces heat transfer from the internal media to the external environment, making the hose safe for direct handling even when conveying high-temperature fluids or gases. The coating also provides enhanced chemical resistance and protects the underlying stainless steel from external environmental factors that could potentially compromise long-term performance.

Manufacturing processes incorporate advanced forming techniques to create uniform corrugation patterns that optimize both flexibility and flow dynamics. The seamless integration of the PVC coating ensures complete coverage while maintaining the hose's flexibility characteristics. This careful attention to manufacturing detail results in a product that delivers consistent performance across a wide range of operating conditions and applications.

Features & Benefits

Superior Material Construction

The foundation of this flexible metal pipe lies in its premium stainless steel construction. This material selection provides exceptional corrosion resistance, making it suitable for use with various media including water, gases, and many chemical compounds. The inherent properties of this steel grade ensure long-term durability and maintain structural integrity even under challenging operating conditions.

Advanced Corrugated Design

The precisely engineered corrugated profile creates multiple advantages over conventional flexible hose designs. This pattern allows for significant lateral movement and angular deflection while maintaining smooth internal flow characteristics. The corrugations distribute stress evenly across the hose structure, preventing fatigue failures that commonly occur in other flexible piping solutions. Additionally, this design enables the hose to compress and extend longitudinally, accommodating thermal expansion and system movement.

Thermal Insulation Properties

The specialized PVC coating provides excellent thermal insulation properties that protect both the surrounding environment and personnel from heat transfer. This feature is particularly valuable in applications involving high-temperature media where traditional uncoated metal hoses would pose safety risks. The insulating properties also help maintain media temperature, reducing energy losses in heating systems and improving overall system efficiency.

Enhanced Safety Features

Safe handling characteristics represent a primary benefit of the 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water PVC-Coated Surface for Heat Insulation & Safe Handling. The PVC coating remains cool to the touch even when the internal media reaches elevated temperatures, eliminating burn risks during installation, maintenance, and operation. The smooth exterior surface also prevents snagging on clothing or equipment, further enhancing workplace safety.

Applications & Use Cases

Industrial gas distribution systems represent a primary application area where this flexible metal pipe excels. The combination of gas-tight construction and thermal insulation makes it ideal for natural gas, propane, and other gaseous media transfer in both commercial and industrial settings. The flexibility allows for easy routing around obstacles and accommodation of equipment vibration without compromising system integrity.

Water and fluid handling applications benefit significantly from the corrosion-resistant properties and flexible design characteristics. Hot water systems, steam condensate lines, and industrial process water applications all leverage the thermal protection and durability offered by this innovative hose design. The smooth internal surface promotes efficient flow while the flexible construction simplifies installation in confined spaces.

HVAC and building services applications frequently require flexible connections that can accommodate building movement and thermal expansion while maintaining system performance. This corrugated hose solution provides the necessary flexibility and thermal properties for heating system connections, ventilation ductwork transitions, and building utility connections where traditional rigid piping would be impractical.

Manufacturing and process industries utilize these hoses for connecting equipment that experiences vibration or requires periodic repositioning. The robust construction withstands industrial environments while the flexible design accommodates machinery movement without creating stress concentrations that could lead to system failures. Chemical processing, food production, and pharmaceutical manufacturing all benefit from the hygienic and corrosion-resistant properties of the stainless steel construction.

Quality Control & Compliance

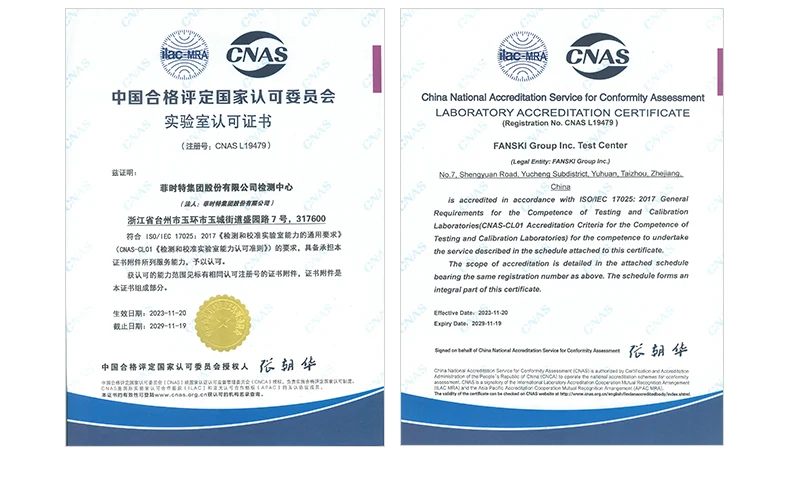

Rigorous quality control processes ensure that every 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water PVC-Coated Surface for Heat Insulation & Safe Handling meets the highest standards for performance and safety. Manufacturing facilities implement comprehensive testing protocols that verify material composition, dimensional accuracy, pressure ratings, and coating integrity. These quality measures ensure consistent product performance and reliability across all production batches.

International compliance standards guide the design and manufacturing processes, ensuring compatibility with global industrial requirements and safety regulations. The stainless steel materials meet recognized industry standards for composition and performance, while the PVC coating materials comply with relevant safety and environmental regulations. This commitment to compliance facilitates international trade and provides confidence for global buyers and distributors.

Traceability systems track materials and manufacturing processes throughout production, enabling complete documentation of product provenance and quality verification. This systematic approach to quality management supports customer quality requirements and provides the documentation necessary for critical applications where performance verification is essential.

Customization & Branding Options

Flexible customization options allow the 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water PVC-Coated Surface for Heat Insulation & Safe Handling to be tailored to specific application requirements and customer preferences. Length customization enables precise fitting for individual installations, eliminating waste and ensuring optimal system design. End connection options can be modified to match existing system requirements, simplifying integration and reducing installation complexity.

PVC coating customization provides opportunities for color coding, labeling, or branding that support system identification and maintenance protocols. Different coating formulations can be applied to optimize specific properties such as chemical resistance, temperature ratings, or UV stability for outdoor applications. These customization capabilities make the product suitable for OEM applications where specific performance characteristics or appearance requirements must be met.

Private labeling and branding services support distributors and system integrators who require customized product identification. Professional marking and packaging options reinforce brand identity while maintaining the technical excellence and quality standards that define this premium flexible hose solution. These services enable partners to offer differentiated products while leveraging proven manufacturing expertise and quality systems.

Packaging & Logistics Support

Sophisticated packaging solutions protect the 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water PVC-Coated Surface for Heat Insulation & Safe Handling during storage and transportation while optimizing shipping efficiency. Protective packaging prevents damage to the PVC coating and maintains the corrugated profile integrity throughout the distribution chain. Packaging designs accommodate various length configurations while minimizing shipping volumes to reduce logistics costs.

International shipping protocols ensure compliance with global transportation regulations and documentation requirements. Proper packaging materials and methods protect products during extended transit times and varying environmental conditions encountered in international shipping. These comprehensive logistics solutions support global distribution networks and enable reliable delivery to international customers and distributors.

Inventory management support includes forecasting assistance and flexible ordering arrangements that help distributors optimize their stock levels while ensuring product availability. Efficient logistics coordination reduces lead times and supports just-in-time delivery requirements that are increasingly important in modern supply chain management. This comprehensive approach to logistics support strengthens partnerships and enables mutual success in competitive markets.

Why Choose Us

Our extensive experience in advanced metal fabrication and flexible piping solutions spans multiple decades of international collaboration with leading industrial organizations across diverse sectors. This deep expertise in materials science, manufacturing processes, and application engineering enables us to deliver innovative products that consistently exceed customer expectations and industry standards. Our global presence and multi-industry expertise provide unique insights into evolving market needs and technological requirements.

As a recognized metal packaging manufacturer and engineering solutions provider, we leverage advanced manufacturing capabilities and quality systems that support both standard products and custom OEM tin packaging solutions. Our commitment to innovation drives continuous improvement in product design, manufacturing efficiency, and customer service excellence. This comprehensive approach positions us as a preferred custom tin box supplier for organizations seeking reliable, high-performance flexible piping solutions.

Strategic partnerships with international distributors and system integrators create a comprehensive support network that ensures product availability and technical assistance worldwide. Our role as a trusted metal packaging supplier extends beyond product delivery to include ongoing technical support, application assistance, and collaborative problem-solving that helps customers optimize their systems and operations. This commitment to partnership success drives long-term relationships built on mutual trust and shared achievement.

Conclusion

The 304 Stainless Steel Corrugated Hose Flexible Metal Pipe for Gas Water PVC-Coated Surface for Heat Insulation & Safe Handling represents an optimal solution for demanding industrial applications requiring the combined benefits of flexibility, durability, thermal protection, and operational safety. Its sophisticated design integrates premium materials with advanced manufacturing techniques to deliver consistent performance across diverse operating conditions and applications. The comprehensive customization options, quality assurance programs, and global logistics support create a complete solution that addresses the complex requirements of modern industrial systems while providing the reliability and performance that define premium flexible piping solutions in today's competitive marketplace.