Introduction

In today's demanding industrial landscape, businesses require reliable fluid transfer solutions that can withstand extreme conditions while maintaining operational integrity. The 304 Stainless Steel Straight Plated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable Chemical represents a breakthrough in engineered piping technology, delivering uncompromising performance across diverse industrial applications. This advanced flexible metal conduit combines superior material science with precision manufacturing to create a solution that addresses the most challenging fluid handling requirements in modern industrial environments.

Engineered for professionals who demand excellence, this flexible metal piping system offers exceptional versatility in connecting equipment, managing thermal expansion, and providing reliable fluid transfer capabilities. The sophisticated design incorporates premium stainless steel construction with specialized plating technology, ensuring long-term durability and consistent performance under extreme operating conditions. This innovative approach to flexible piping represents the evolution of industrial fluid handling solutions, meeting the increasingly complex demands of contemporary manufacturing and processing environments.

Product Overview

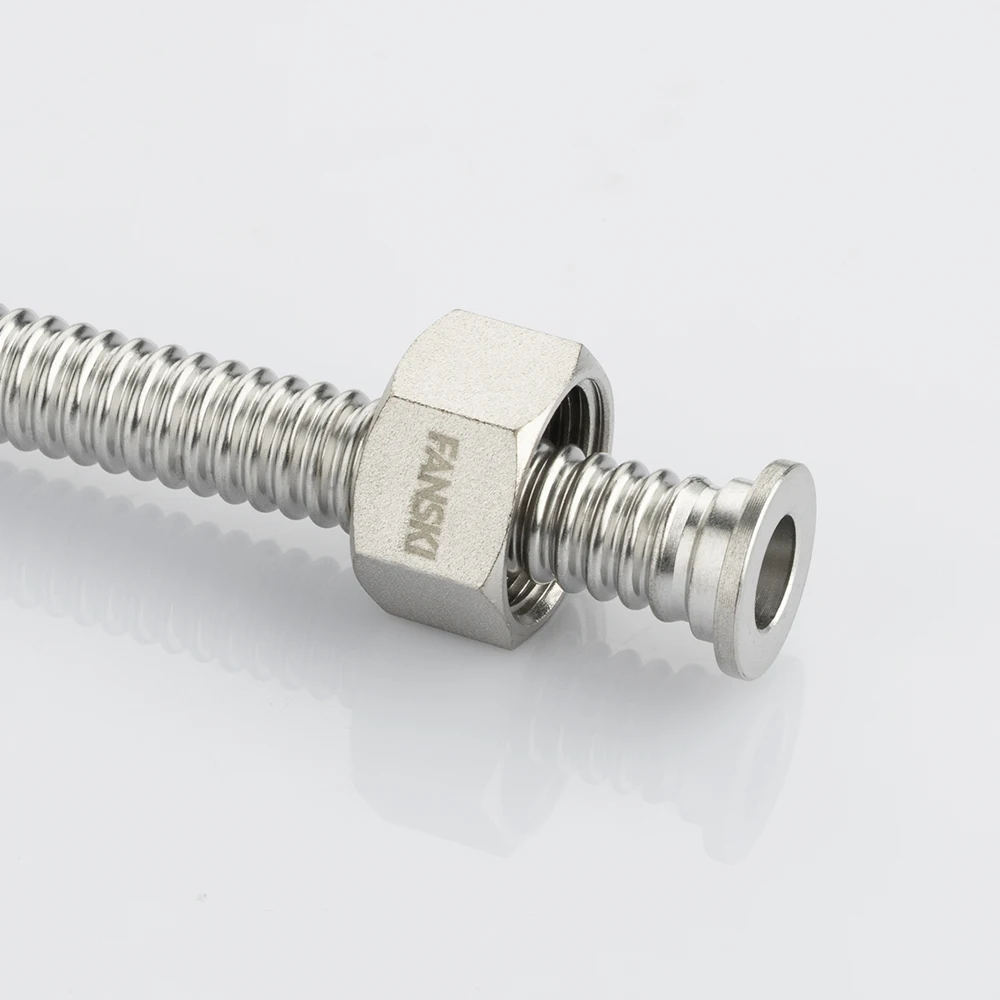

The 304 Stainless Steel Straight Plated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable Chemical features advanced austenitic stainless steel construction that provides exceptional corrosion resistance and mechanical strength. The sophisticated plating process enhances surface properties while maintaining the inherent flexibility required for dynamic applications. This flexible metal conduit system incorporates engineered corrugations that allow for multi-directional movement while maintaining structural integrity under pressure and temperature variations.

The innovative design philosophy behind this flexible metal piping solution emphasizes durability without compromising operational flexibility. The specialized manufacturing process creates a seamless integration of strength and adaptability, enabling the system to accommodate thermal expansion, vibration absorption, and misalignment compensation. The premium stainless steel composition ensures compatibility with a wide range of media types while maintaining consistent performance characteristics throughout extended service cycles.

This advanced piping system represents a significant advancement in flexible metal conduit technology, incorporating lessons learned from decades of industrial application experience. The refined engineering approach balances material properties with functional requirements, creating a solution that exceeds traditional performance expectations while providing enhanced reliability in critical applications.

Features & Benefits

Superior Material Composition

The foundation of this flexible metal piping system lies in its premium stainless steel construction, which provides exceptional resistance to corrosion, oxidation, and chemical attack. The specialized plating process enhances surface characteristics while preserving the material's inherent flexibility and strength properties. This combination creates a piping solution that maintains structural integrity while accommodating dynamic operational requirements.

Enhanced Temperature Performance

The 304 Stainless Steel Straight Plated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable Chemical demonstrates remarkable thermal stability across extended temperature ranges. The advanced metallurgy and specialized manufacturing processes ensure consistent performance under extreme thermal conditions while maintaining flexibility for thermal expansion management. This thermal resilience makes the system ideal for applications involving significant temperature variations or continuous high-temperature operation.

Chemical Compatibility Excellence

The sophisticated material composition provides broad chemical compatibility, enabling safe handling of various industrial fluids, gases, and process media. The enhanced surface properties resulting from the specialized plating process create additional barriers against chemical interaction while maintaining the system's operational flexibility. This comprehensive chemical resistance ensures reliable performance across diverse industrial applications and process environments.

Mechanical Durability

The engineered design incorporates advanced corrugation geometry that optimizes stress distribution while maximizing operational flexibility. The precision manufacturing process ensures consistent wall thickness and surface finish, contributing to enhanced fatigue resistance and extended service life. This mechanical excellence enables the system to withstand repeated flexing, vibration exposure, and pressure cycling without compromising structural integrity.

Applications & Use Cases

The versatile design of the 304 Stainless Steel Straight Plated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable Chemical makes it suitable for numerous industrial applications across diverse sectors. In petrochemical processing facilities, this flexible metal conduit provides reliable connections between equipment while accommodating thermal expansion and operational vibrations. The superior chemical resistance ensures safe handling of aggressive process media while maintaining system integrity under demanding operational conditions.

Food and beverage processing operations benefit significantly from the hygienic properties and easy cleaning characteristics of this stainless steel piping system. The smooth surface finish and chemical inertness make it ideal for sanitary applications where product purity and contamination prevention are paramount. The flexible design enables efficient equipment connections while accommodating cleaning procedures and maintenance access requirements.

Pharmaceutical manufacturing environments utilize this flexible metal piping for critical process connections where material purity and contamination control are essential. The specialized plating process and premium stainless steel construction ensure compatibility with stringent pharmaceutical standards while providing the operational flexibility required for complex processing equipment arrangements. The system's ability to maintain integrity under sterilization procedures makes it invaluable for pharmaceutical applications.

Power generation facilities employ this flexible piping solution for steam, condensate, and cooling water applications where thermal cycling and vibration management are critical operational considerations. The exceptional temperature resistance and mechanical durability ensure reliable performance in power plant environments while accommodating the dynamic conditions inherent in energy generation operations.

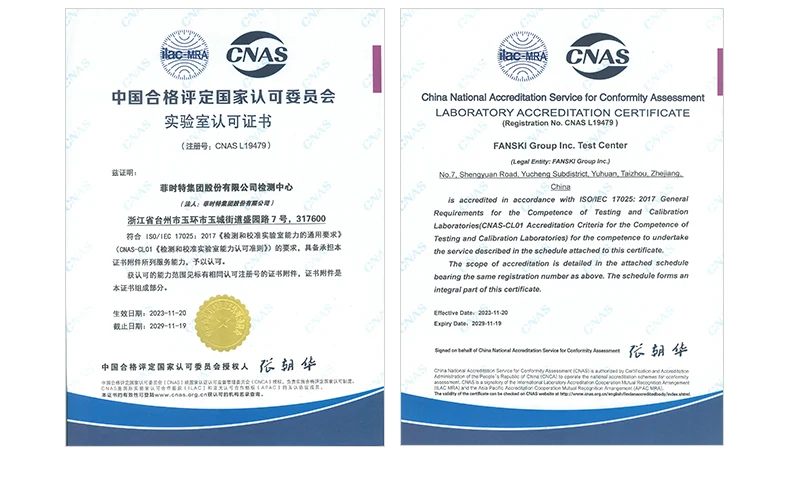

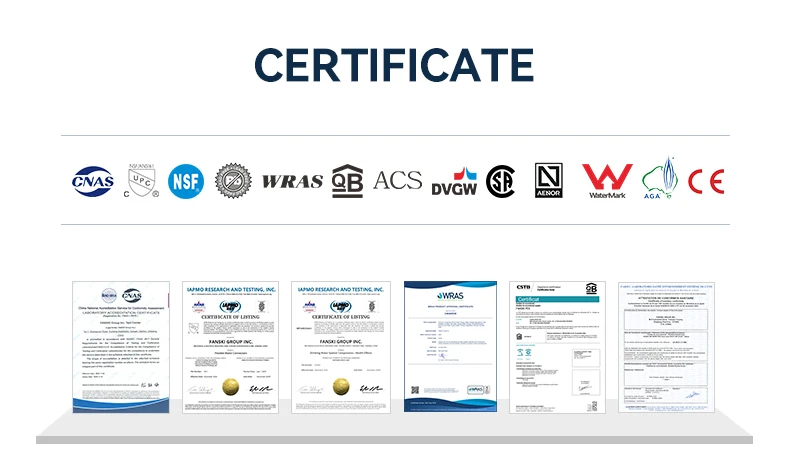

Quality Control & Compliance

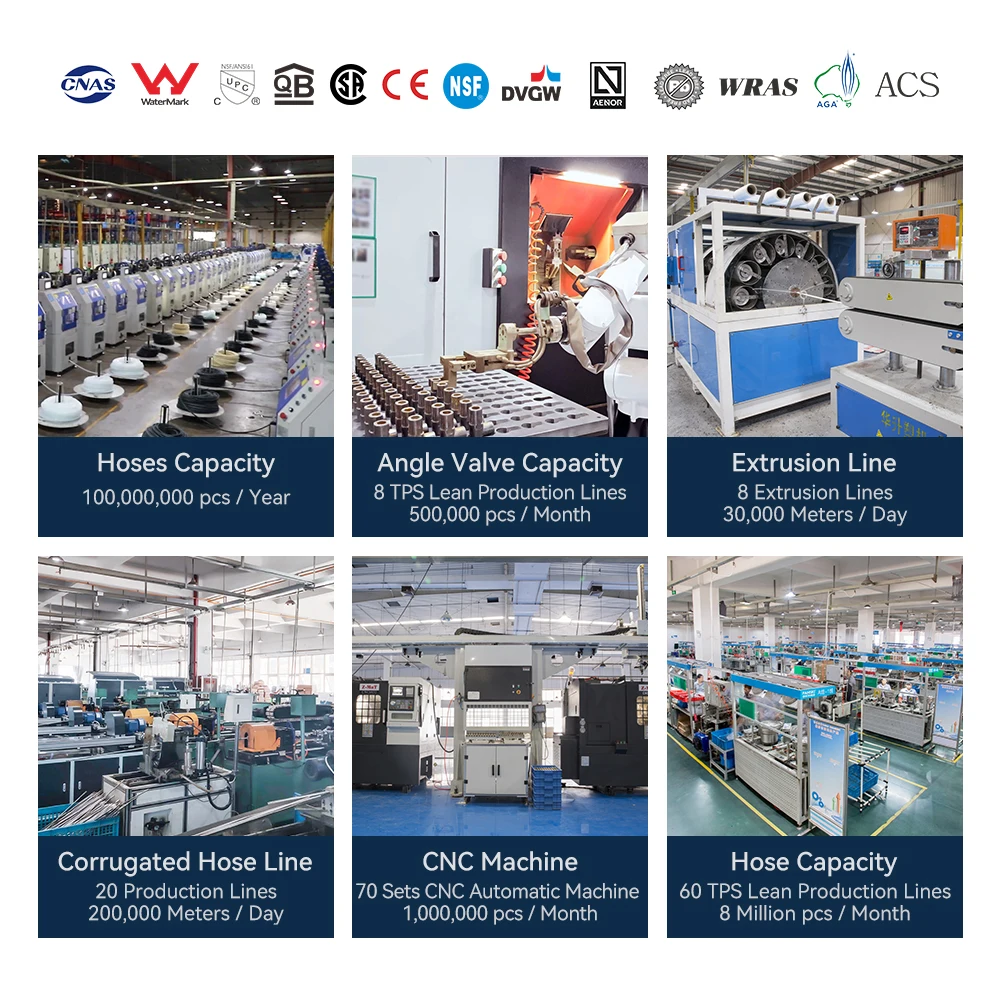

Manufacturing excellence forms the cornerstone of quality assurance for the 304 Stainless Steel Straight Plated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable Chemical. Advanced quality control protocols encompass every stage of production, from raw material verification through final inspection and testing. The comprehensive quality management system ensures consistent product characteristics and reliable performance across all manufacturing batches.

Material traceability systems maintain complete documentation of steel composition and manufacturing processes, enabling full accountability and quality verification. Advanced testing procedures validate mechanical properties, dimensional accuracy, and surface finish characteristics before products enter distribution channels. This rigorous approach to quality control ensures that each flexible metal conduit meets established performance standards and application requirements.

International compliance standards guide manufacturing processes and quality verification procedures, ensuring global market acceptability and application suitability. The commitment to regulatory compliance extends beyond basic requirements to encompass emerging standards and evolving industry best practices. This proactive approach to compliance ensures continued market access and application approval across diverse international markets.

Customization & Branding Options

Understanding that industrial applications often require specialized solutions, comprehensive customization capabilities accommodate unique operational requirements and system specifications. Engineering teams collaborate with clients to develop tailored configurations that optimize performance for specific applications while maintaining the fundamental advantages of the flexible metal piping system. This collaborative approach ensures optimal integration with existing equipment and operational procedures.

Advanced manufacturing capabilities enable modifications to length specifications, end connection types, and surface treatments to meet particular application requirements. The flexible manufacturing approach accommodates both standard industrial configurations and specialized custom solutions without compromising quality or performance characteristics. This adaptability ensures optimal system integration across diverse industrial environments and operational requirements.

As an experienced metal packaging manufacturer with extensive industrial piping expertise, custom branding and identification marking services are available to support client specifications and inventory management requirements. The sophisticated marking capabilities include laser etching, stamping, and specialized identification systems that maintain legibility under operational conditions while meeting traceability requirements.

Packaging & Logistics Support

Comprehensive packaging solutions protect product integrity during transportation while optimizing logistics efficiency and handling convenience. Advanced packaging materials and techniques ensure that the 304 Stainless Steel Straight Plated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable Chemical arrives in perfect condition regardless of shipping distance or handling requirements. The sophisticated packaging approach considers both product protection and environmental responsibility.

Logistics coordination capabilities encompass global shipping requirements and international trade compliance, ensuring smooth delivery processes across diverse international markets. The experienced logistics team manages documentation, customs procedures, and delivery coordination to minimize delays and ensure timely arrival. This comprehensive logistics support eliminates complications associated with international industrial equipment procurement.

Specialized handling procedures accommodate the unique characteristics of flexible metal piping products while maintaining efficiency in warehouse operations and distribution processes. The coordinated approach to packaging and logistics ensures product integrity from manufacturing facility to final installation while optimizing cost-effectiveness and delivery reliability.

Why Choose Us

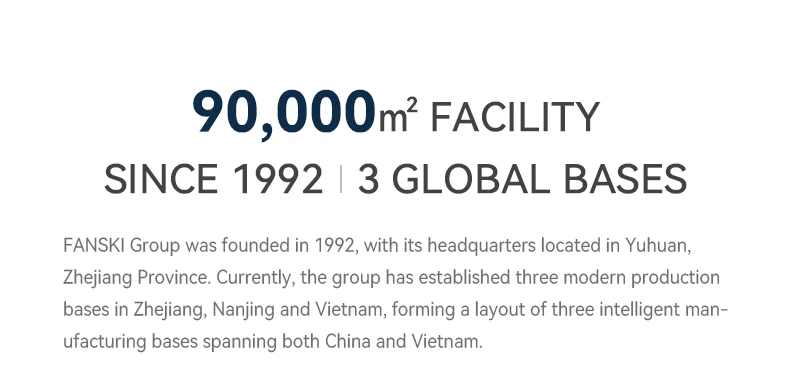

With extensive experience serving international industrial markets, our company has established a reputation for delivering exceptional flexible metal piping solutions that exceed performance expectations. Our commitment to engineering excellence and manufacturing precision has earned recognition from clients across diverse industrial sectors, from petrochemical processing to pharmaceutical manufacturing. This proven track record demonstrates our capability to deliver reliable solutions that meet the most demanding operational requirements.

As a recognized custom tin box supplier and industrial piping specialist, our comprehensive understanding of material science and manufacturing processes enables us to provide solutions that combine innovative design with proven reliability. Our global presence and international collaboration experience ensure that we understand diverse market requirements and regulatory standards, enabling us to serve clients effectively regardless of their operational location or industry sector.

The integration of advanced manufacturing technologies with traditional craftsmanship creates products that represent the pinnacle of flexible metal piping performance. Our commitment to continuous improvement and technological advancement ensures that our solutions remain at the forefront of industry development while maintaining the reliability and durability that industrial applications demand. This dedication to excellence extends throughout our entire product portfolio, ensuring consistent quality across all offerings.

Conclusion

The 304 Stainless Steel Straight Plated Hose Flexible Metal Pipe for Gas Water High Temperature Resistance Durable Chemical represents the convergence of advanced materials science, precision engineering, and manufacturing excellence to create a flexible piping solution that meets the demanding requirements of modern industrial applications. The sophisticated combination of superior stainless steel construction, specialized plating technology, and engineered flexibility delivers uncompromising performance across diverse operational environments and application requirements. This innovative approach to flexible metal conduit design ensures reliable operation under extreme conditions while providing the operational flexibility essential for dynamic industrial processes. The comprehensive quality assurance, customization capabilities, and global logistics support make this flexible metal piping system the optimal choice for industrial professionals who demand excellence in their fluid handling solutions.