Introduction

In the demanding world of water heating systems and industrial plumbing applications, reliable connections are paramount to ensuring optimal performance and longevity. The 304 Stainless Steel Straight Plated Hose WATER HEATER CONNECTORS Corrugated Hose Bellows in Various Lengths and Configurations represents a pinnacle of engineering excellence, designed to meet the diverse needs of commercial, residential, and industrial water heating installations. These premium connectors combine superior material properties with innovative design features to deliver exceptional durability, flexibility, and corrosion resistance in the most challenging environments.

As water heating systems continue to evolve with advancing technology and stricter efficiency standards, the importance of high-quality connection components cannot be overstated. These stainless steel corrugated hose bellows serve as critical interface elements that accommodate thermal expansion, vibration dampening, and angular misalignment while maintaining secure, leak-proof connections. Their versatile design makes them indispensable components for distributors, contractors, and system integrators seeking reliable solutions for modern water heating applications.

Product Overview

The 304 Stainless Steel Straight Plated Hose WATER HEATER CONNECTORS Corrugated Hose Bellows in Various Lengths and Configurations feature premium-grade stainless steel construction that delivers exceptional resistance to corrosion, oxidation, and chemical degradation. The corrugated bellows design provides superior flexibility while maintaining structural integrity under pressure and temperature variations commonly encountered in water heating systems. Each connector undergoes precision manufacturing processes to ensure consistent quality and reliable performance across diverse installation scenarios.

These connectors are engineered with straight-through flow paths that minimize pressure drop and turbulence, optimizing system efficiency while reducing energy consumption. The plated finish enhances both aesthetic appeal and functional performance, providing additional protection against environmental factors that could compromise long-term reliability. Available in multiple length options and configuration variations, these connectors accommodate a wide range of installation requirements and system specifications.

The bellows construction incorporates advanced forming techniques that create uniform wall thickness and consistent flexibility characteristics throughout the connector length. This engineering approach ensures predictable performance under cyclic loading conditions and thermal cycling, extending service life while maintaining leak-proof sealing integrity. The straight configuration simplifies installation procedures while providing optimal flow characteristics for maximum system efficiency.

Features & Benefits

Superior Material Properties

The use of grade stainless steel in these water heater connectors provides exceptional corrosion resistance across a broad spectrum of water chemistries and environmental conditions. This high-performance alloy maintains its mechanical properties and surface integrity even when exposed to aggressive water conditions, chlorinated water supplies, and elevated temperatures commonly found in commercial and residential water heating applications. The material's inherent antimicrobial properties also contribute to maintaining water quality and system hygiene.

Advanced Bellows Design

The corrugated bellows configuration delivers outstanding flexibility while accommodating thermal expansion and contraction cycles inherent in water heating systems. This design feature significantly reduces stress concentrations at connection points, preventing premature failure and extending overall system life. The bellows structure also provides excellent vibration dampening characteristics, reducing noise transmission and protecting connected equipment from mechanical stress.

Enhanced Flow Characteristics

The straight-through design maintains optimal flow paths that minimize pressure losses and eliminate flow restrictions that could compromise system performance. This engineering approach ensures maximum heat transfer efficiency while reducing pumping energy requirements. The smooth internal surfaces further enhance flow characteristics and prevent scale buildup that could reduce system efficiency over time.

Versatile Configuration Options

Available in various lengths and configurations, these 304 Stainless Steel Straight Plated Hose WATER HEATER CONNECTORS Corrugated Hose Bellows in Various Lengths and Configurations accommodate diverse installation requirements and space constraints. This flexibility enables contractors and system designers to select optimal connector specifications for specific applications while maintaining consistent quality and performance standards across different project requirements.

Applications & Use Cases

These premium stainless steel connectors find extensive application in residential water heating systems where reliability and longevity are essential for homeowner satisfaction and reduced maintenance requirements. Tank-style water heaters, tankless units, and hybrid heating systems all benefit from the superior flexibility and corrosion resistance provided by these specialized connectors. The ability to accommodate thermal expansion and building settlement makes them particularly valuable in residential installations where access for maintenance may be limited.

Commercial and institutional water heating applications represent another significant market segment where these connectors deliver exceptional value. Hotels, hospitals, schools, and office buildings require robust water heating infrastructure that can operate reliably under continuous demand conditions. The 304 Stainless Steel Straight Plated Hose WATER HEATER CONNECTORS Corrugated Hose Bellows in Various Lengths and Configurations provide the durability and performance consistency necessary for these demanding applications while simplifying maintenance procedures and reducing lifecycle costs.

Industrial process heating applications benefit significantly from the chemical resistance and high-temperature capabilities of these stainless steel connectors. Manufacturing facilities, food processing plants, and chemical processing operations often require specialized connection solutions that can withstand aggressive environments while maintaining leak-proof integrity. The bellows design accommodates equipment movement and thermal cycling while ensuring reliable operation in critical process applications.

Renewable energy systems, including solar water heating and geothermal installations, utilize these connectors to manage the unique challenges associated with variable temperature conditions and system cycling. The superior corrosion resistance and flexibility characteristics make them ideal for outdoor installations and closed-loop systems where traditional connection methods may prove inadequate over extended service periods.

Quality Control & Compliance

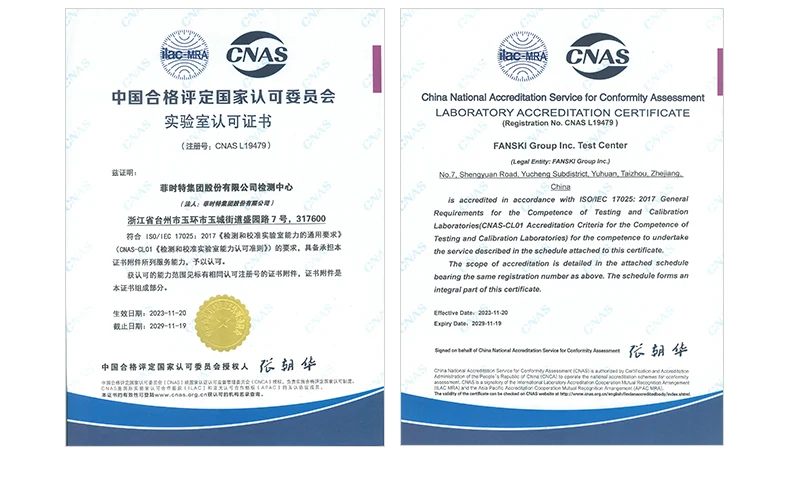

Manufacturing excellence forms the foundation of these premium water heater connectors, with comprehensive quality control procedures ensuring consistent performance and reliability across all product variations. Each connector undergoes rigorous testing protocols that verify pressure integrity, dimensional accuracy, and material compliance with industry specifications. Advanced inspection techniques, including radiographic examination and pressure testing, validate structural integrity and leak-proof performance under operating conditions.

Material certification and traceability procedures ensure that all stainless steel components meet stringent quality standards for chemical composition, mechanical properties, and surface finish characteristics. These quality assurance measures provide confidence for distributors and end-users while supporting compliance with building codes and industry regulations governing water heating system components.

Environmental compliance considerations are integral to the manufacturing process, with sustainable production practices and material selection supporting green building initiatives and environmental stewardship goals. The long service life and recyclability of stainless steel components contribute to reduced environmental impact while delivering superior performance compared to alternative connection methods.

International quality standards guide all aspects of design, manufacturing, and testing procedures to ensure global compatibility and acceptance across diverse markets and regulatory environments. This commitment to quality excellence supports international distribution channels while providing consistent performance expectations for contractors and system integrators worldwide.

Customization & Branding Options

Understanding the diverse needs of global markets and specific application requirements, these water heater connectors can be adapted to meet unique specifications and performance criteria. Custom length options accommodate specific installation constraints while maintaining the superior performance characteristics that define these premium components. Engineering support services assist distributors and contractors in selecting optimal configurations for challenging applications or specialized system requirements.

Surface finish variations and marking options provide opportunities for brand differentiation while maintaining the functional excellence that customers expect from these high-quality connectors. Custom packaging solutions support distributor requirements and enhance product presentation in competitive markets. These customization capabilities enable partners to develop specialized product offerings that address specific market segments or application niches.

As an experienced metal packaging manufacturer with extensive capabilities in custom fabrication, our organization understands the importance of tailored solutions that meet specific customer requirements. This expertise extends to developing specialized connector configurations that address unique installation challenges while maintaining the quality standards that define our product portfolio.

Technical documentation and certification services support custom applications with comprehensive performance data and compliance verification. This service capability enables distributors and contractors to specify these connectors with confidence while ensuring regulatory compliance and optimal system performance in demanding applications.

Packaging & Logistics Support

Professional packaging solutions protect these precision-manufactured connectors during transportation and storage while facilitating efficient handling and installation procedures. Protective packaging materials prevent surface damage and contamination that could compromise performance or appearance. Individual component protection ensures that each connector arrives in perfect condition, ready for immediate installation without additional cleaning or preparation requirements.

Inventory management support includes flexible packaging quantities and standardized shipping configurations that accommodate diverse distributor requirements and market demands. Efficient logistics coordination reduces lead times while ensuring product availability when needed for time-sensitive projects. These support services enhance distributor capabilities while reducing inventory carrying costs and improving cash flow management.

Documentation packages include technical specifications, installation guidelines, and performance data that support proper application and optimal system design. Clear labeling and identification systems facilitate inventory management and ensure correct product selection for specific applications. This comprehensive approach to product support reduces installation errors while optimizing system performance and reliability.

Global shipping capabilities and logistics partnerships enable efficient distribution to international markets while maintaining product integrity throughout the supply chain. Specialized handling procedures and protective packaging ensure that these precision components arrive in perfect condition regardless of shipping distance or handling requirements.

Why Choose Us

With decades of experience serving international markets and a proven track record of delivering innovative metal packaging solutions, our organization brings unmatched expertise to the development and manufacturing of premium water heater connectors. Our commitment to engineering excellence and quality manufacturing has established strong partnerships with distributors and contractors across multiple continents, demonstrating our ability to deliver consistent value in diverse market environments.

As a recognized custom tin box supplier and OEM tin packaging solutions provider, we understand the critical importance of precision manufacturing and quality control in component applications where reliability is paramount. This expertise translates directly to our water heating connector products, ensuring that each component meets the highest standards for performance and durability while supporting our partners' success in competitive markets.

Our comprehensive approach to product development combines advanced materials science with practical application experience to deliver solutions that exceed customer expectations. Collaborative relationships with international partners provide valuable market insights that guide continuous improvement initiatives and new product development efforts. This global perspective ensures that our products remain at the forefront of industry innovation while meeting evolving customer needs.

Investment in advanced manufacturing capabilities and quality control systems demonstrates our commitment to maintaining leadership in premium component manufacturing. Continuous improvement initiatives and technology adoption ensure that our production processes remain efficient and competitive while delivering consistent quality across all product lines. This dedication to excellence supports long-term partnerships and customer satisfaction in demanding applications.

Conclusion

The 304 Stainless Steel Straight Plated Hose WATER HEATER CONNECTORS Corrugated Hose Bellows in Various Lengths and Configurations represent the pinnacle of connection technology for modern water heating applications. Through superior material selection, innovative design engineering, and precision manufacturing processes, these connectors deliver unmatched performance, reliability, and longevity across diverse installation scenarios. Their versatile configuration options and exceptional quality characteristics make them the preferred choice for contractors, distributors, and system integrators who demand the highest standards of performance and reliability. The combination of advanced materials, proven design principles, and comprehensive quality assurance ensures that these connectors will continue to provide exceptional value and performance throughout their extended service life, supporting the success of water heating systems worldwide while contributing to overall system efficiency and customer satisfaction.