Introduction

Modern commercial and residential plumbing installations demand reliable, space-efficient valve solutions that deliver consistent performance across diverse applications. The FANSKI Brass Angle Valves ABS Handle Washing Machine Faucets Mini Space Saving Automatic Water Seal Hotel Use Modern represents a breakthrough in compact valve design, specifically engineered for environments where space optimization meets functional excellence. This innovative valve system combines premium brass construction with advanced automatic water sealing technology, making it an ideal choice for hospitality facilities, residential developments, and commercial laundry installations worldwide.

As global infrastructure projects increasingly prioritize efficiency and reliability, these specialized angle valves address the critical need for dependable water control systems in constrained spaces. The integration of durable ABS handle components with precision-engineered brass valve bodies creates a product that balances cost-effectiveness with long-term performance, positioning it as a preferred solution for international buyers seeking quality plumbing components.

Product Overview

The FANSKI Brass Angle Valves ABS Handle Washing Machine Faucets Mini Space Saving Automatic Water Seal Hotel Use Modern features a sophisticated design philosophy that maximizes functionality within minimal footprint requirements. The brass construction ensures exceptional corrosion resistance and longevity, while the ABS handle provides ergonomic operation and aesthetic appeal. This unique combination addresses the demanding requirements of modern plumbing systems where space constraints and performance standards must be simultaneously satisfied.

These angle valves incorporate automatic water sealing mechanisms that eliminate common leakage issues associated with traditional valve designs. The compact form factor enables installation in tight spaces typically found in hotel bathrooms, apartment utility areas, and commercial laundry facilities. The modern aesthetic complements contemporary interior design trends while maintaining the robust functionality required for heavy-duty applications.

The valve system demonstrates exceptional versatility in connection compatibility, accommodating various pipe configurations commonly encountered in international markets. This adaptability reduces inventory complexity for distributors while ensuring consistent performance across different regional plumbing standards and installation requirements.

Features & Benefits

Premium Brass Construction

The valve body utilizes high-grade brass alloy that provides superior resistance to water-induced corrosion and mineral buildup. This material selection ensures extended service life even in challenging water conditions, making these valves particularly suitable for regions with hard water or aggressive chemical compositions. The brass construction also enables excellent thermal stability, maintaining seal integrity across wide temperature ranges commonly encountered in washing machine applications.

Advanced ABS Handle Technology

The ABS handle construction delivers exceptional durability while offering enhanced grip characteristics that facilitate easy operation even in wet conditions. The material's inherent resistance to UV degradation and chemical exposure ensures consistent appearance and functionality throughout the product's operational life. The ergonomic design reduces operator fatigue during frequent use scenarios typical in commercial laundry environments.

Automatic Water Seal Innovation

The integrated automatic water sealing system represents a significant advancement in valve technology, providing reliable closure without requiring excessive torque or maintenance intervention. This feature significantly reduces the likelihood of water waste due to incomplete closure while extending the operational life of internal sealing components. The automatic sealing mechanism adapts to varying water pressures, maintaining consistent performance across diverse installation conditions.

Space-Saving Design Philosophy

The compact configuration enables installation in areas where traditional valve designs would be impractical or impossible. This space-saving approach proves particularly valuable in hotel renovations, apartment retrofits, and new construction projects where maximizing usable space is paramount. The reduced footprint also simplifies maintenance access while minimizing visual impact in finished installations.

Applications & Use Cases

The FANSKI Brass Angle Valves ABS Handle Washing Machine Faucets Mini Space Saving Automatic Water Seal Hotel Use Modern excel in hospitality environments where reliability and aesthetic appeal are equally important. Hotel laundry facilities benefit from the valves' ability to withstand frequent operation while maintaining consistent performance. The modern design complements contemporary hotel aesthetics while the automatic sealing technology reduces maintenance requirements and associated operational disruptions.

Residential applications find particular value in the space-saving characteristics, especially in apartment buildings and condominiums where utility areas must accommodate multiple functions within limited square footage. The valves' compact design enables washing machine installations in previously unusable spaces, expanding housing developers' flexibility in unit layout optimization.

Commercial laundry operations appreciate the robust construction and automatic sealing features that minimize downtime and maintenance costs. The brass construction withstands the demanding operational environment typical of commercial washing facilities while the ABS handles resist damage from frequent use. These characteristics make the valves particularly suitable for multi-housing developments, hotels, and institutional facilities requiring reliable water control systems.

Industrial applications benefit from the valves' ability to maintain consistent performance in challenging environments. The automatic water seal technology proves especially valuable in facilities where water conservation is critical, while the compact design enables installation in equipment configurations where space limitations would otherwise compromise functionality.

Quality Control & Compliance

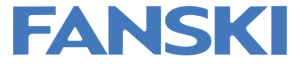

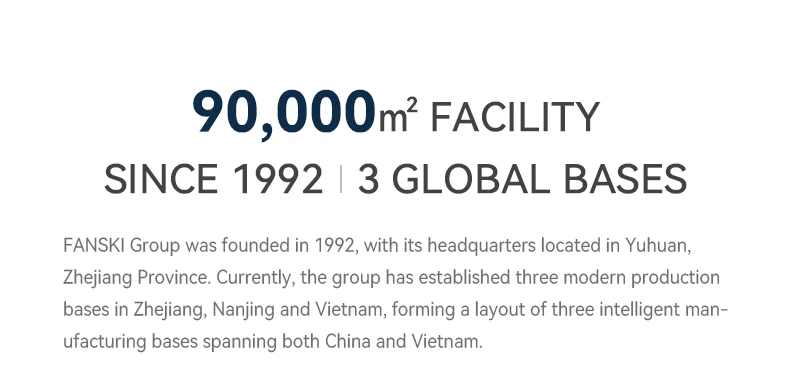

Manufacturing excellence defines every aspect of the FANSKI Brass Angle Valves production process, with comprehensive quality control measures ensuring consistent performance across all units. The brass components undergo rigorous material verification procedures to confirm alloy composition and mechanical properties, while the ABS handles are subjected to stress testing that simulates extended operational use. These quality assurance protocols ensure that each valve meets the demanding standards required for international distribution.

The automatic water sealing mechanism receives particular attention during quality validation, with each unit undergoing pressure testing that verifies seal integrity across the entire operational pressure range. This testing protocol ensures reliable performance in diverse installation conditions while identifying potential issues before products reach end users. The comprehensive approach to quality control minimizes field failures and supports the product's reputation for dependability.

International compliance standards guide the manufacturing and testing processes, ensuring compatibility with regional plumbing codes and installation requirements. The valves meet stringent performance criteria for water control applications while maintaining the safety standards required for residential and commercial installations. This compliance foundation facilitates smooth market entry across diverse geographical regions and regulatory environments.

Customization & Branding Options

The FANSKI Brass Angle Valves platform accommodates various customization requirements that enable distributors and OEMs to differentiate their offerings while maintaining the core performance characteristics. Handle color variations provide aesthetic flexibility for projects with specific design requirements, while custom marking options support brand identification and traceability needs. These customization capabilities enhance market positioning opportunities without compromising the fundamental quality and performance standards.

Private label opportunities enable distributors to establish their brand presence in local markets while leveraging the proven performance characteristics of the FANSKI valve design. The customization process maintains strict quality control standards, ensuring that modified versions deliver the same reliability and performance as standard configurations. This approach supports long-term partnerships between manufacturers and distributors seeking to build sustainable market presence.

Technical modifications can accommodate specific regional requirements or unique application demands, with engineering support available to evaluate feasibility and implementation approaches. The flexible manufacturing platform enables reasonable adaptation requests while preserving the core design principles that ensure reliable operation and extended service life.

Packaging & Logistics Support

Professional packaging solutions protect the FANSKI Brass Angle Valves ABS Handle Washing Machine Faucets Mini Space Saving Automatic Water Seal Hotel Use Modern during international shipping while supporting efficient distribution operations. The packaging design minimizes dimensional waste while providing adequate protection for the brass and ABS components throughout the logistics chain. Individual unit protection prevents damage during handling while bulk packaging options optimize shipping efficiency for larger orders.

Documentation support includes comprehensive installation guides and technical specifications that facilitate proper installation and operation. Multi-language documentation options accommodate international markets while detailed drawings and specifications support professional installers and maintenance personnel. The documentation package includes troubleshooting guides that minimize support requirements while ensuring optimal performance throughout the product lifecycle.

Logistics coordination services streamline the international shipping process, with experienced personnel managing documentation requirements and shipping arrangements. The comprehensive approach to logistics support reduces administrative burden for international buyers while ensuring timely delivery and proper handling throughout the shipping process. This support foundation enables smooth transactions and reliable supply chain performance.

Why Choose Us

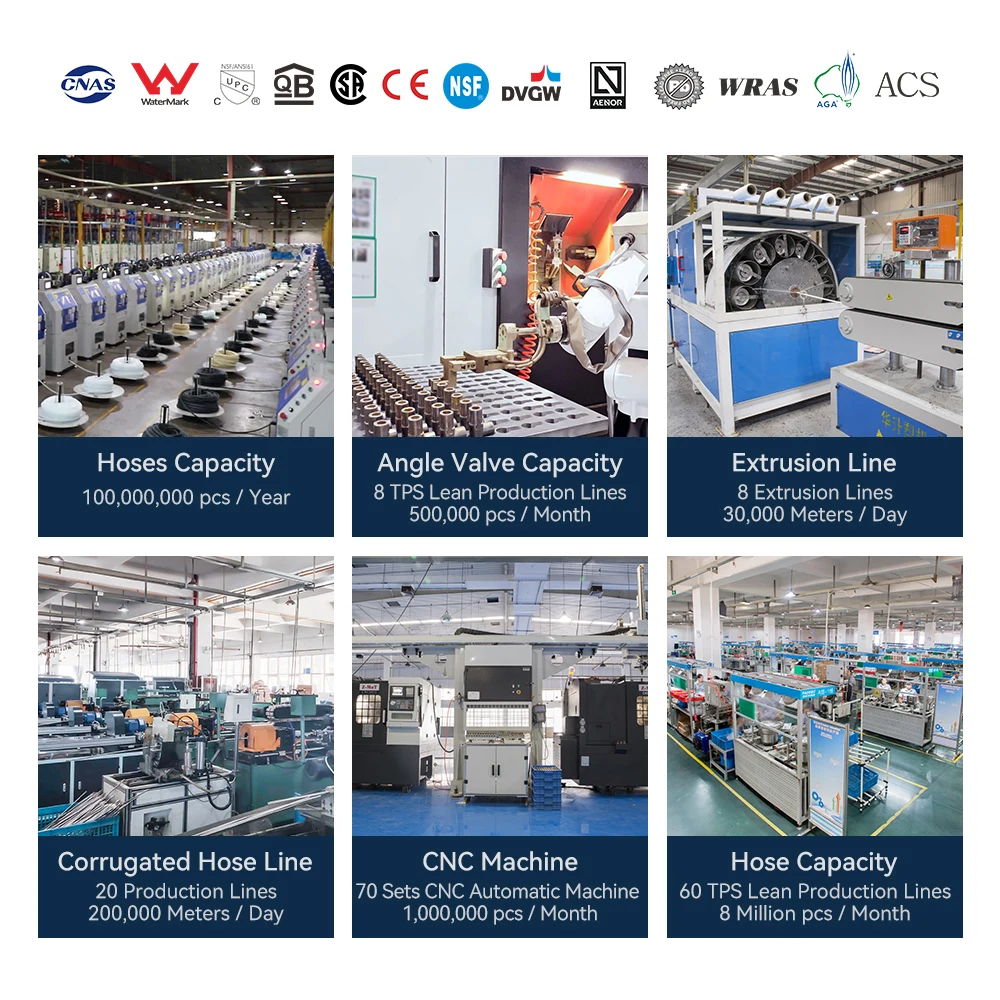

Our organization brings decades of experience in precision valve manufacturing, with established expertise in serving international markets across multiple continents. This extensive background enables us to understand the diverse requirements and challenges faced by global buyers, distributors, and end users. The FANSKI Brass Angle Valves represent the culmination of this experience, incorporating lessons learned from thousands of installations worldwide into a refined and reliable product design.

As a recognized metal packaging manufacturer with comprehensive capabilities in precision component production, we maintain rigorous quality standards that ensure consistent performance across all product lines. Our facility combines advanced manufacturing technology with experienced personnel, creating a production environment that consistently delivers products meeting international quality expectations. This foundation supports long-term relationships with distributors and OEMs seeking reliable supplier partnerships.

The company's commitment to innovation drives continuous improvement in product design and manufacturing processes, ensuring that our valve solutions remain competitive in evolving market conditions. Our engineering team maintains awareness of emerging trends and technological developments, incorporating relevant advances into product development initiatives. This forward-thinking approach ensures that customers receive products that meet current requirements while providing adaptability for future needs.

International market presence enables us to understand regional preferences and requirements, facilitating product development that addresses diverse market needs. Our collaboration with distributors and end users across multiple industries provides valuable feedback that guides product refinement and new product development. This market-driven approach ensures that our solutions remain relevant and competitive in dynamic global markets.

Conclusion

The FANSKI Brass Angle Valves ABS Handle Washing Machine Faucets Mini Space Saving Automatic Water Seal Hotel Use Modern represents an ideal solution for applications requiring reliable water control in space-constrained environments. The combination of premium brass construction, innovative ABS handle technology, and automatic water sealing capabilities creates a product that addresses the demanding requirements of modern plumbing installations while providing the aesthetic appeal required for contemporary applications. The space-saving design philosophy enables installation opportunities that would be impossible with traditional valve configurations, expanding options for architects, engineers, and facility managers worldwide. Through comprehensive quality control, flexible customization options, and professional logistics support, these valves provide a complete solution for international buyers seeking dependable, efficient, and aesthetically pleasing valve systems for their projects.

Product Name |

Washing Machine Bib Cock |

Specification |

G1/2 |

Material of Body |

Refined Brass |

Material of Catridge |

Ceramic |

Material of Handle |

ABS |

Finish |

Chromed |

Max Temperature |

90℃ |

WARRANTY |

10 Years |

LOSS COVERAGE/CASE/USD |

2 Million |

Logo |

Customized logo welcomed |

Packing |

Standard export package or customized |

A:Yes. we're professional manufacture in China,and have been in this field for more

than 30 years.

Q:What payment terms do you support?

A: T/T,L/C,DP,DDU,DDP etc are available, and for T/T we accept 30% deposit in advance,70% balance against copy of B/L.

A:In-stock items typically ship within a week. Out-of-stock items usually ship within 4-6 weeks, while custom orders depend on your specific design requirements.

Q:How long is your delivery time for the item without stock?

A:30-40 days after receiving deposit.

Q:lt is possible to get samples from your factory?

A:Yes. Free samples will be sent if needed, but the freight can be negotiated or chargeable, it will be refunded after

confirmation of the order.

Q:Can l use my own logo or design on your products?

A:Absolutely yes. We offer OEM/ODM services to customize products with your logo or design.

Q:Do you operate your own factories?

A:Yes, we have factories in Zhejiang and Vietnam. We also work closely with other reliable manufacturers to meet different needs.You' re welcome to visit us.

Q:What is your production capacity?

A:For the products of flexible hose,we can make 8 million pieces a month and for the angle valve,we can make 1.6 million pieces a month. We also maintain strong partnerships with other suppliers to ensure timely and reliable deliveries.

Q:How do you choose your suppliers?

A:We rigorously select suppliers based on their performance in domestic projects focusing on their production capacity, delivery reliability, and quality control. Our own quality team oversees this process.

A:Yes, we provide after-sales support with warranties ranging from 3 to 20 years depending on the product. Please contact us for more information.

Q:Do you accept small orders?

A:Yes, we welcome the orders that it may meet our requirement of MOQ for different products. We are committed to providing excellent service to every customer.