Introduction

The demand for reliable gas transmission solutions in industrial and commercial applications continues to drive innovation in flexible pipe technology. Our Hot Sale 304 Stainless Steel 304 Flexible Gas Line Metal Pipe Welded Plumbing Hoses Gas Connector for Gas System represents the pinnacle of engineering excellence in gas distribution infrastructure. These premium flexible gas connectors are engineered to deliver superior performance, safety, and longevity across diverse gas system applications, making them an essential component for contractors, engineers, and facility managers worldwide.

Modern gas distribution systems require components that can withstand varying pressures, temperatures, and environmental conditions while maintaining absolute safety standards. This flexible gas line solution addresses these critical requirements through advanced stainless steel construction and precision welding techniques that ensure leak-proof connections and exceptional durability. The sophisticated design incorporates industry-leading materials science to deliver a product that exceeds conventional expectations for gas transmission components.

Product Overview

This premium stainless steel flexible gas connector represents a breakthrough in gas line technology, combining the inherent benefits of high-grade stainless steel with innovative flexible design principles. The welded construction methodology ensures superior structural integrity while maintaining the flexibility required for complex installation scenarios. Each unit undergoes rigorous manufacturing processes that guarantee consistent quality and performance characteristics essential for critical gas system applications.

The Hot Sale 304 Stainless Steel 304 Flexible Gas Line Metal Pipe Welded Plumbing Hoses Gas Connector for Gas System features advanced corrugated construction that provides exceptional flexibility without compromising structural strength. This design approach allows for easy installation in confined spaces, around obstacles, and in applications where rigid piping would be impractical or impossible. The stainless steel composition ensures resistance to corrosion, oxidation, and chemical degradation, making these connectors suitable for both indoor and outdoor installations.

The welded construction technique employed in manufacturing these gas connectors utilizes state-of-the-art fusion welding processes that create seamless joints throughout the assembly. This approach eliminates potential weak points that could develop over time, ensuring long-term reliability and safety in gas transmission applications. The precision manufacturing standards applied during production result in consistent wall thickness, optimal flexibility characteristics, and superior pressure resistance capabilities.

Features & Benefits

Superior Material Properties

The choice of high-grade stainless steel as the primary construction material provides numerous advantages over alternative materials commonly used in gas line applications. Stainless steel offers exceptional resistance to environmental factors including moisture, temperature fluctuations, and chemical exposure that can compromise the integrity of lesser materials. The inherent strength characteristics of stainless steel enable these flexible connectors to maintain their structural properties under significant mechanical stress while providing the flexibility necessary for dynamic installations.

The corrosion resistance properties of stainless steel construction ensure these gas connectors maintain their performance characteristics throughout extended service life cycles. Unlike carbon steel or other ferrous materials that may develop rust or corrosion over time, stainless steel maintains its structural integrity and appearance regardless of environmental exposure conditions. This characteristic significantly reduces maintenance requirements and extends the operational lifespan of gas distribution systems where these connectors are installed.

Advanced Welding Technology

The welded construction methodology represents a significant advancement over traditional mechanical connection systems commonly found in flexible gas line products. Welded joints eliminate the potential for loosening that can occur with threaded or clamped connections, providing superior long-term reliability and safety margins. The precision welding processes used in manufacturing create metallurgical bonds that are stronger than the base material itself, ensuring exceptional durability under operational stress conditions.

Each welded joint undergoes comprehensive quality verification processes that confirm proper penetration, fusion characteristics, and structural integrity. This attention to welding quality ensures that every Hot Sale 304 Stainless Steel 304 Flexible Gas Line Metal Pipe Welded Plumbing Hoses Gas Connector for Gas System meets stringent performance standards required for critical gas system applications. The welding techniques employed also maintain the flexibility characteristics of the connector while providing superior pressure containment capabilities.

Optimal Flexibility Design

The corrugated design profile of these flexible gas connectors provides exceptional bending capabilities without creating stress concentrations that could lead to premature failure. This design approach allows for installation in tight spaces, around corners, and in configurations that would be impossible with rigid piping systems. The flexibility characteristics enable these connectors to absorb thermal expansion, vibration, and minor structural movements without transmitting stress to connected equipment or piping systems.

The engineered flexibility also facilitates easier installation procedures, reducing labor costs and installation time compared to rigid pipe systems that require precise measurements, cutting, and fitting. Installation crews can route these flexible connectors along optimal paths without the need for multiple joints, elbows, and specialized fittings that increase system complexity and potential failure points. This installation advantage translates to significant cost savings and improved system reliability for end users.

Applications & Use Cases

These premium flexible gas connectors find extensive application across diverse industrial and commercial sectors where reliable gas transmission is essential. Commercial kitchen installations represent a primary application area where the flexibility and durability of stainless steel construction provide superior performance compared to traditional rigid piping systems. The ability to route gas lines around equipment, through walls, and into confined spaces makes these connectors invaluable for restaurant, hotel, and institutional food service applications.

Industrial facilities utilizing natural gas, propane, or other gaseous fuels benefit significantly from the flexibility and reliability offered by these welded stainless steel connectors. Manufacturing plants, processing facilities, and power generation installations require gas distribution systems that can accommodate equipment vibration, thermal expansion, and operational dynamics while maintaining absolute safety standards. The Hot Sale 304 Stainless Steel 304 Flexible Gas Line Metal Pipe Welded Plumbing Hoses Gas Connector for Gas System addresses these requirements through superior engineering and construction quality.

Residential and commercial heating system installations represent another significant application area where these flexible connectors provide essential advantages over rigid piping alternatives. HVAC contractors appreciate the installation flexibility that allows for efficient routing around structural elements, through walls, and into equipment rooms where space constraints make traditional piping challenging. The durability and safety characteristics of stainless steel construction ensure long-term reliability in heating system applications where operational safety is paramount.

Laboratory and research facility applications demand the highest levels of safety and reliability in gas distribution systems. These flexible stainless steel connectors meet the stringent requirements of scientific and medical gas applications where contamination concerns and safety protocols require materials that maintain their integrity under all operational conditions. The welded construction eliminates potential leak paths that could compromise sensitive experiments or create safety hazards in controlled environments.

Quality Control & Compliance

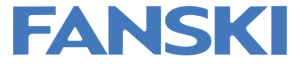

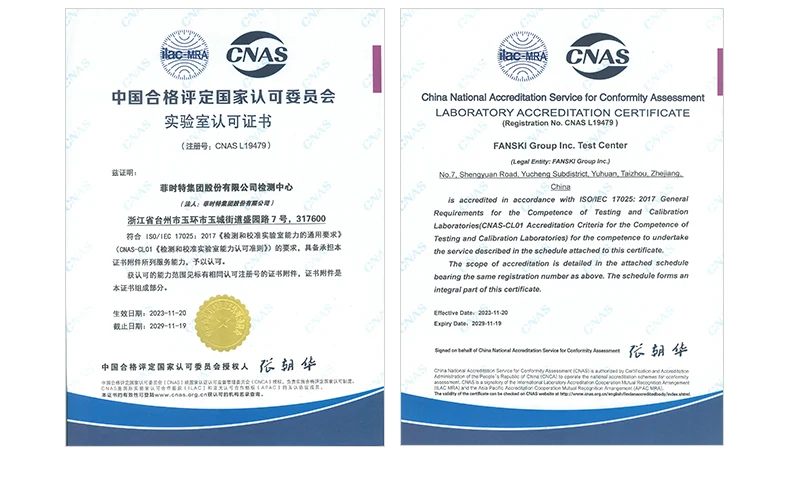

Comprehensive quality assurance programs govern every aspect of production for these premium flexible gas connectors, ensuring consistent performance characteristics and reliability standards that exceed industry expectations. Advanced testing protocols verify material properties, welding integrity, pressure resistance, and flexibility characteristics throughout the manufacturing process. These quality control measures guarantee that each unit meets stringent performance criteria essential for critical gas system applications.

Material certification programs trace the stainless steel content from raw material suppliers through final product completion, providing comprehensive documentation of chemical composition, mechanical properties, and processing history. This traceability ensures that only materials meeting specified grade requirements are utilized in production, maintaining the consistent quality characteristics that professional installers and end users depend upon for reliable system performance.

Pressure testing protocols subject each flexible gas connector to rigorous evaluation under controlled conditions that simulate and exceed typical operational requirements. These tests verify the structural integrity of welded joints, confirm pressure containment capabilities, and validate flexibility characteristics under stress conditions. The comprehensive testing approach ensures that products delivered to customers meet or exceed all applicable safety and performance standards required for gas transmission applications.

International compliance standards guide the design and manufacturing processes to ensure compatibility with global installation requirements and safety regulations. These standards encompass material specifications, construction methodologies, performance criteria, and safety factors that provide confidence for international distributors and end users. Adherence to recognized industry standards facilitates product acceptance across diverse markets and regulatory environments worldwide.

Customization & Branding Options

Recognizing the diverse requirements of different markets and applications, comprehensive customization capabilities enable adaptation of these flexible gas connectors to meet specific customer requirements and specifications. Engineering teams work closely with customers to develop solutions that address unique installation challenges, environmental conditions, or performance requirements that may not be addressed by standard product configurations. This collaborative approach ensures optimal performance in specialized applications while maintaining the quality and safety standards inherent in the base product design.

Custom tin box supplier relationships enable specialized packaging solutions that protect these precision-engineered gas connectors during shipping and storage while providing professional presentation that supports customer branding initiatives. OEM tin packaging solutions can incorporate customer logos, specifications, and installation instructions that enhance product recognition and facilitate proper installation procedures. These packaging capabilities support distributors and contractors who require professional presentation for their customer base.

Private labeling options allow qualified distributors to market these premium flexible gas connectors under their own brand identity while maintaining the quality and performance characteristics that define the product. This approach enables market expansion through established distribution channels while providing customers with consistent quality standards regardless of the branding configuration. The flexibility in branding arrangements supports diverse business models and market strategies for qualified partners.

Technical specification modifications can address specific regional requirements, unique application demands, or customer preferences while maintaining the core performance characteristics that define these premium gas connectors. Engineering support services assist customers in determining optimal configurations for their specific applications, ensuring proper performance while maintaining compliance with applicable safety and regulatory standards.

Packaging & Logistics Support

Sophisticated packaging systems protect these precision-engineered flexible gas connectors throughout the global supply chain, ensuring that products arrive at their destination in perfect condition ready for immediate installation. Advanced protective packaging materials and techniques prevent damage from impacts, moisture, and environmental factors that could compromise product integrity during shipping and storage. The packaging approach considers the specific characteristics of stainless steel construction and the flexibility requirements that must be maintained throughout the distribution process.

Metal packaging manufacturer partnerships provide specialized container solutions that offer superior protection while optimizing shipping efficiency and cost effectiveness. These custom packaging solutions incorporate advanced materials and design principles that protect products while minimizing shipping volumes and weights. The result is reduced transportation costs and environmental impact while maintaining the highest levels of product protection throughout the distribution chain.

Global logistics capabilities support efficient distribution to international markets through established partnerships with shipping providers and customs handling specialists. These partnerships ensure that products move efficiently through international trade channels while maintaining proper documentation and compliance with import regulations. The logistics infrastructure supports both large volume shipments to major distributors and smaller quantities for specialized applications or urgent requirements.

Inventory management systems coordinate production scheduling with customer demand patterns to ensure optimal availability while minimizing carrying costs for distributors and end users. Advanced planning systems consider lead times, seasonal demand variations, and regional market requirements to maintain appropriate inventory levels throughout the distribution network. This approach ensures product availability when needed while supporting efficient cash flow management for all participants in the supply chain.

Why Choose Us

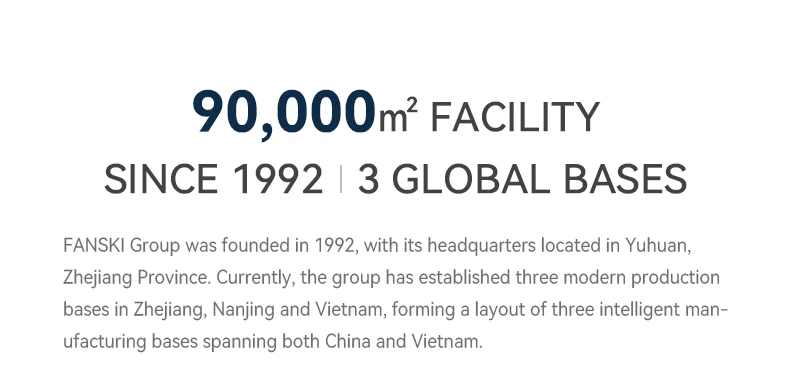

Our commitment to excellence in flexible gas connector manufacturing spans over many yearss of continuous innovation and quality improvement, establishing us as a trusted metal packaging supplier and engineering solutions provider to customers across six continents. This extensive experience encompasses diverse applications, challenging environments, and stringent quality requirements that have shaped our understanding of what customers need for successful gas system installations. The knowledge gained through years of customer collaboration and technical innovation is embedded in every aspect of our manufacturing processes and product development initiatives.

International market presence provides deep understanding of regional requirements, regulatory standards, and customer preferences that influence product design and manufacturing approaches. This global perspective ensures that our Hot Sale 304 Stainless Steel 304 Flexible Gas Line Metal Pipe Welded Plumbing Hoses Gas Connector for Gas System meets diverse market needs while maintaining consistent quality standards worldwide. The ability to adapt products for different markets while preserving core performance characteristics demonstrates our commitment to customer success across diverse applications and environments.

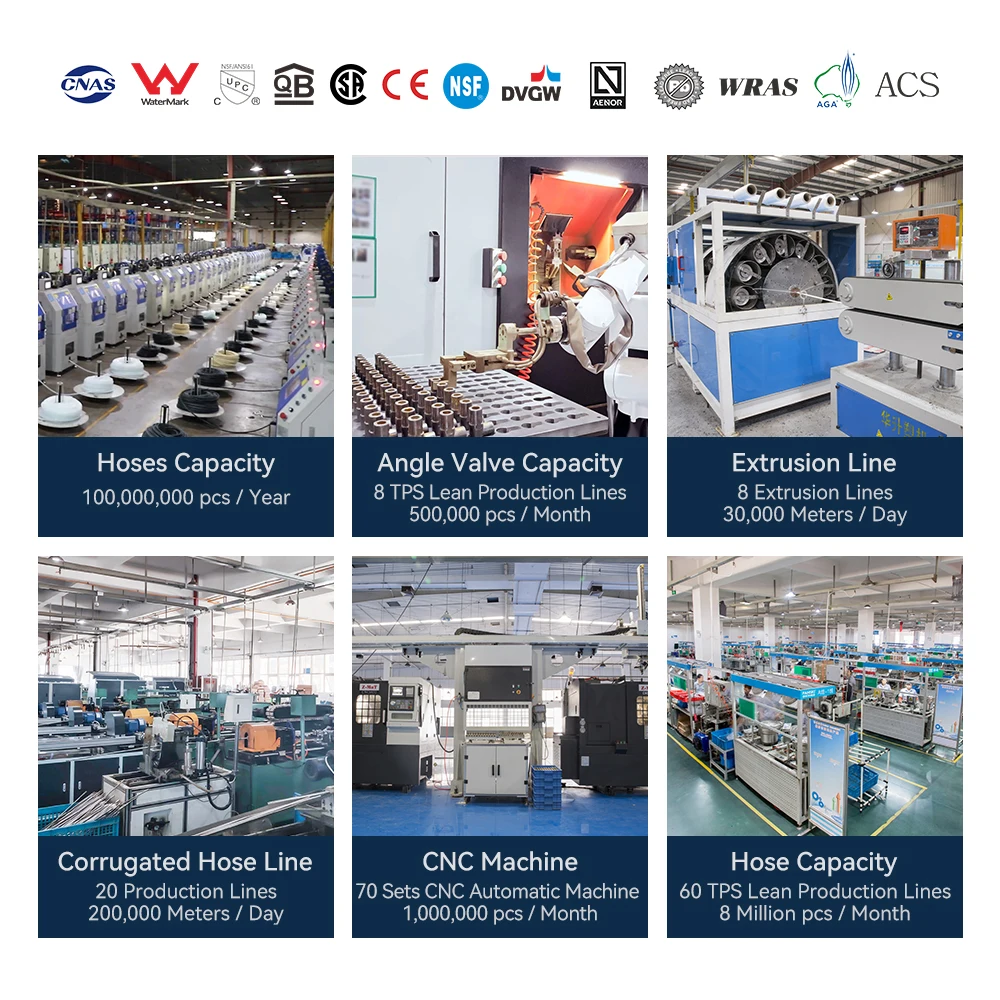

Advanced manufacturing capabilities incorporate cutting-edge technology, precision equipment, and quality systems that consistently deliver products exceeding customer expectations. Investment in manufacturing technology ensures that production processes remain at the forefront of industry standards while maintaining the flexibility to accommodate custom requirements and evolving market demands. This technological foundation supports both high-volume production efficiency and the precision manufacturing required for specialized applications.

Technical expertise encompasses materials science, welding technology, fluid dynamics, and safety engineering disciplines that contribute to superior product performance and reliability. Our engineering teams collaborate with customers to solve challenging installation problems, optimize system performance, and develop innovative solutions that address evolving market requirements. This technical depth ensures that customers receive not just products, but comprehensive solutions that enhance their operational success and competitive position.

Conclusion

The Hot Sale 304 Stainless Steel 304 Flexible Gas Line Metal Pipe Welded Plumbing Hoses Gas Connector for Gas System represents the convergence of advanced materials technology, precision manufacturing, and innovative design principles that address the critical requirements of modern gas distribution systems. Through superior stainless steel construction, advanced welding techniques, and optimized flexibility characteristics, these premium connectors deliver the performance, safety, and reliability that professional installers and end users demand for critical applications. The comprehensive approach to quality control, customization capabilities, and global distribution support ensures that customers receive solutions that exceed expectations while providing long-term value and operational success. Investment in these premium flexible gas connectors represents a commitment to safety, reliability, and operational excellence that benefits all stakeholders throughout the product lifecycle.