Introduction

In today's demanding industrial and residential markets, reliable gas connection solutions are essential for safe and efficient operations. The Modern Durable Gas Corrugated 304 Stainless Steel Flexible Hose for Water Heater and Kitchen Use represents a breakthrough in flexible gas line technology, combining superior material engineering with practical design excellence. This innovative flexible gas connector addresses the growing need for dependable, long-lasting gas distribution systems in both commercial kitchens and residential water heating applications. As global safety standards continue to evolve, professionals across multiple industries seek robust solutions that deliver consistent performance while maintaining the highest safety protocols.

The corrugated stainless steel construction offers unmatched flexibility and durability, making it an ideal choice for installations where traditional rigid piping proves inadequate. Whether connecting gas appliances in tight spaces or routing gas lines around obstacles, this flexible hose solution provides the versatility that modern installations demand. Its universal compatibility with various gas systems ensures seamless integration across diverse applications, from commercial food service establishments to residential heating systems.

Product Overview

This premium flexible gas hose showcases advanced metallurgical engineering through its high-grade stainless steel construction. The corrugated design maximizes flexibility while maintaining structural integrity under varying pressure conditions and temperature fluctuations. Each hose features precision-engineered fittings that ensure secure connections with standard gas line components, eliminating concerns about leakage or compatibility issues.

The Modern Durable Gas Corrugated 304 Stainless Steel Flexible Hose for Water Heater and Kitchen Use incorporates sophisticated manufacturing techniques that result in consistent wall thickness and optimal corrosion resistance. The internal smooth bore design minimizes pressure drop while the external corrugated profile provides exceptional flexibility for complex routing requirements. This dual-design approach ensures maximum gas flow efficiency while accommodating the most challenging installation scenarios.

Built to withstand the rigorous demands of commercial environments, this flexible gas connector maintains its performance characteristics across extended service periods. The stainless steel construction resists oxidation, chemical degradation, and thermal cycling, making it suitable for applications ranging from high-volume restaurant kitchens to residential water heater installations.

Features & Benefits

Superior Material Engineering

The premium stainless steel alloy composition provides exceptional resistance to corrosion, chemical attack, and thermal stress. This advanced material selection ensures long-term reliability in environments where traditional materials might deteriorate. The metallurgical properties of the stainless steel construction maintain structural integrity even under extreme temperature variations, making it suitable for both indoor and challenging installation environments.

Enhanced Flexibility and Durability

The corrugated design architecture delivers remarkable flexibility while preserving the hose's ability to withstand mechanical stress. This unique construction allows for easy installation around corners, through tight spaces, and in configurations where rigid piping would be impractical. The flexibility extends the service life by reducing stress concentrations that commonly cause premature failure in less sophisticated designs.

Optimized Gas Flow Characteristics

Internal design optimization ensures minimal pressure drop across the hose length, maintaining consistent gas delivery to connected appliances. The smooth interior surface reduces turbulence and friction losses, contributing to overall system efficiency. This flow optimization becomes particularly important in applications requiring precise gas delivery rates for optimal appliance performance.

Universal Compatibility

Engineered to integrate seamlessly with standard gas system components, this flexible hose eliminates compatibility concerns across diverse applications. The precision-manufactured fittings ensure reliable connections with existing infrastructure while maintaining the highest safety standards. This universal approach simplifies inventory management for distributors and installers working across multiple project types.

Applications & Use Cases

The versatility of the Modern Durable Gas Corrugated 304 Stainless Steel Flexible Hose for Water Heater and Kitchen Use makes it an essential component across numerous industries and applications. In commercial food service environments, these flexible connectors provide reliable gas supply to cooking equipment, allowing for easy appliance positioning and maintenance access. The flexibility proves invaluable when connecting gas ranges, ovens, and specialized cooking equipment in space-constrained commercial kitchens.

Residential water heating systems benefit significantly from the flexible design, particularly in basement installations where routing around structural elements is necessary. The corrosion-resistant properties ensure reliable performance in humid environments commonly found in utility rooms and mechanical spaces. Home builders and plumbing contractors appreciate the installation flexibility that reduces labor time while maintaining safety standards.

Industrial applications include process heating systems, laboratory equipment connections, and specialized manufacturing environments where gas-powered equipment requires flexible connections. The robust construction withstands the demanding conditions found in industrial facilities while providing the reliability essential for continuous operations. Food processing facilities, chemical plants, and manufacturing operations rely on this type of flexible gas connection for critical process equipment.

HVAC contractors frequently specify these flexible hoses for boiler connections, furnace installations, and other heating system applications. The ability to accommodate thermal expansion and building settlement makes them ideal for permanent installations in both commercial and residential heating systems. The professional appearance and reliable performance meet the expectations of quality-conscious contractors and building owners.

Quality Control & Compliance

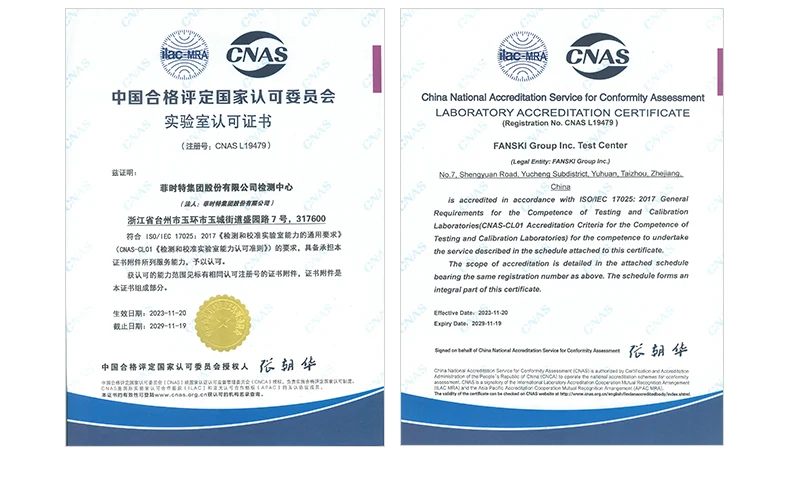

Manufacturing excellence begins with rigorous material verification processes that ensure each stainless steel component meets stringent metallurgical standards. Advanced testing protocols validate material composition, mechanical properties, and corrosion resistance characteristics before production begins. This comprehensive approach to quality assurance establishes the foundation for reliable long-term performance.

Each Modern Durable Gas Corrugated 304 Stainless Steel Flexible Hose for Water Heater and Kitchen Use undergoes extensive pressure testing to verify structural integrity and leak-tight performance. Specialized testing equipment subjects every hose to conditions exceeding normal operating parameters, ensuring safety margins that protect end users and installations. Quality control procedures include visual inspection, dimensional verification, and functional testing to maintain consistent product standards.

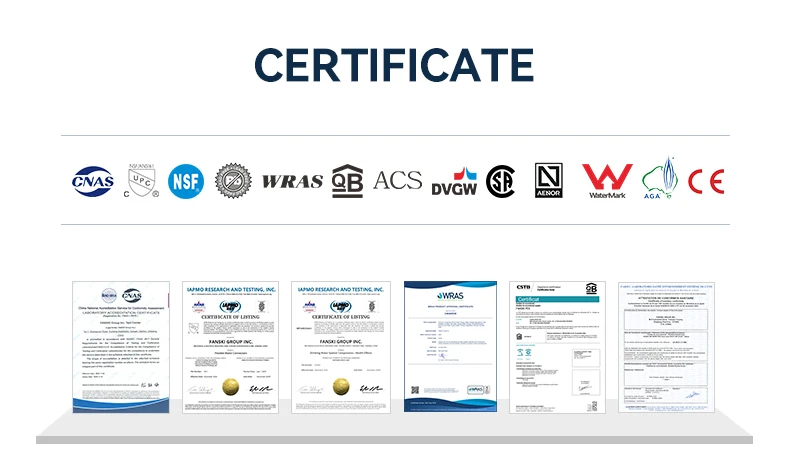

International safety standards guide the design and manufacturing processes, ensuring global market acceptance and regulatory compliance. The quality management system incorporates continuous improvement methodologies that enhance product reliability while maintaining cost-effectiveness. Documentation procedures provide complete traceability throughout the manufacturing process, supporting quality investigations and continuous improvement initiatives.

Environmental testing validates performance under extreme conditions including temperature cycling, vibration exposure, and chemical compatibility scenarios. These comprehensive testing protocols ensure product suitability across diverse installation environments and operating conditions. The commitment to quality extends beyond manufacturing to include packaging, handling, and storage procedures that preserve product integrity throughout the distribution chain.

Customization & Branding Options

Understanding the diverse needs of global markets, extensive customization capabilities accommodate specific application requirements and regional preferences. Length variations, fitting configurations, and specialized end connections can be tailored to meet unique project specifications. This flexibility supports distributors and contractors working on specialized installations where standard configurations may not be optimal.

Private labeling opportunities enable distributors to develop their own branded product lines while leveraging proven manufacturing expertise. Custom packaging solutions, including specialized labeling and documentation, support brand development initiatives and market differentiation strategies. These branding options help establish market presence while maintaining the quality standards that end users expect.

Technical customization extends to specialized applications requiring unique performance characteristics or installation requirements. Engineering support services assist in developing solutions for challenging applications where standard products may not fully address specific needs. This collaborative approach ensures optimal performance while maintaining safety standards and regulatory compliance.

OEM partnerships provide opportunities for equipment manufacturers to integrate flexible gas connections directly into their products. Custom fitting designs, specialized materials, and unique performance characteristics can be developed to support specific equipment requirements. These partnerships leverage manufacturing expertise while providing equipment manufacturers with reliable, cost-effective component solutions.

Packaging & Logistics Support

Professional packaging solutions protect product integrity throughout the global distribution process while optimizing shipping efficiency. Specialized protective materials prevent damage during handling and transportation, ensuring that products arrive in perfect condition. Packaging design considers both protection requirements and ease of handling for distributors and end users.

Comprehensive logistics support includes flexible shipping options that accommodate diverse global requirements. Container loading optimization reduces shipping costs while protective packaging ensures product integrity during long-distance transportation. Documentation support includes all necessary paperwork for international shipments, customs clearance, and regulatory compliance.

Inventory management support helps distributors optimize stock levels while ensuring product availability for critical applications. Forecasting assistance and demand planning services help prevent stockouts while minimizing inventory carrying costs. These value-added services support distributor success and end-user satisfaction.

Technical documentation accompanies each shipment, providing installation guidelines, safety information, and performance specifications. Multi-language documentation support ensures global market accessibility while comprehensive technical data supports professional installations. This documentation approach reinforces product quality and supports proper installation practices.

Why Choose Us

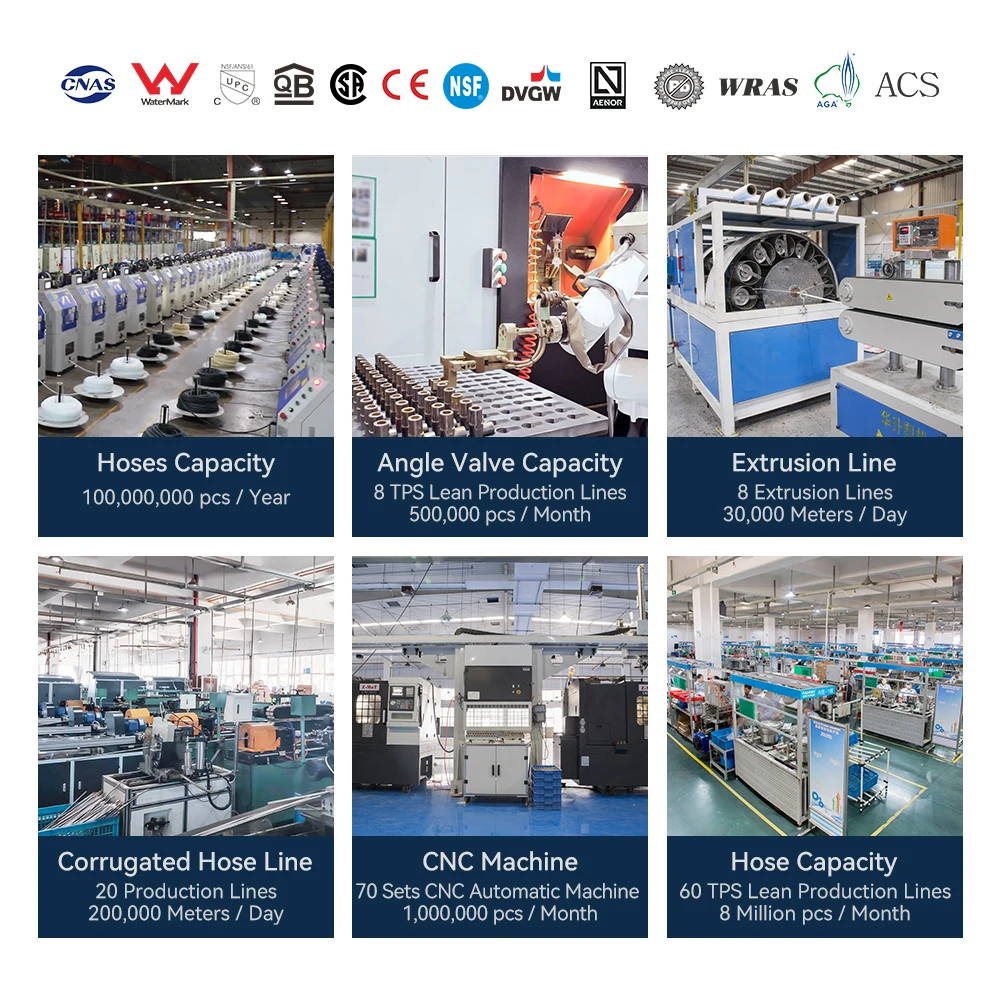

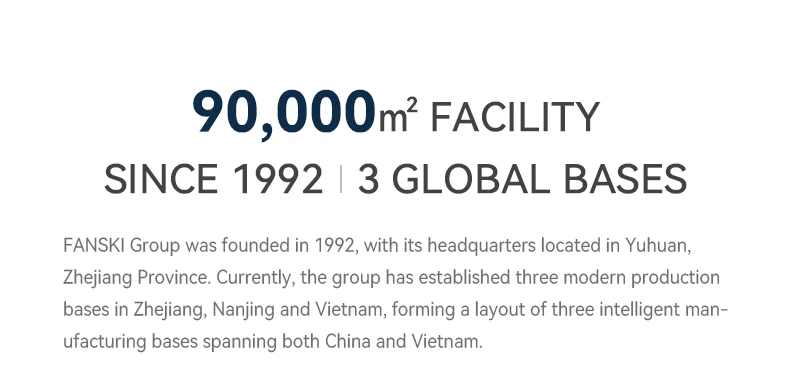

With decades of experience serving international markets, our organization has established a reputation for manufacturing excellence and customer service throughout the global metal packaging and industrial component sectors. Our comprehensive understanding of diverse market requirements enables us to deliver solutions that consistently exceed customer expectations while maintaining competitive positioning in challenging global markets.

As a recognized metal packaging manufacturer with extensive experience in custom tin box supplier services, we bring sophisticated manufacturing capabilities to the flexible gas hose market. Our OEM tin packaging solutions expertise translates into advanced manufacturing processes that ensure consistent quality and reliability. This cross-industry experience provides unique insights into material science, manufacturing optimization, and quality control procedures.

Strategic partnerships with leading distributors and contractors worldwide have validated our commitment to product excellence and customer support. These relationships provide valuable market feedback that drives continuous product improvement and innovation initiatives. Our role as a trusted metal packaging supplier has established quality standards that extend across all product lines.

Advanced manufacturing facilities incorporate the latest production technologies and quality control systems to ensure consistent product performance. Continuous investment in equipment upgrades and process improvements maintains our competitive position while supporting product development initiatives. Environmental responsibility and sustainable manufacturing practices demonstrate our commitment to global corporate citizenship.

Technical support services include application engineering assistance, installation guidance, and troubleshooting support that helps customers achieve optimal results. Our global service network ensures responsive support regardless of geographic location or time zone differences. This comprehensive support approach builds long-term customer relationships and supports market expansion initiatives.

Conclusion

The Modern Durable Gas Corrugated 304 Stainless Steel Flexible Hose for Water Heater and Kitchen Use represents the convergence of advanced materials engineering, sophisticated manufacturing processes, and practical design excellence. This innovative solution addresses the critical need for reliable, flexible gas connections across diverse applications while maintaining the highest safety and performance standards. The combination of superior stainless steel construction, optimized flexibility, and universal compatibility makes it an essential component for professional installations in commercial, residential, and industrial environments. Through comprehensive quality control procedures, extensive customization options, and robust logistics support, this flexible gas hose solution provides the reliability and performance that today's demanding markets require, establishing it as the preferred choice for quality-conscious professionals worldwide.