Introduction

Professional plumbing installations demand components that deliver exceptional durability, reliability, and performance under demanding conditions. The FANKSI Kitchen Water Plumbing Hose Stainless Steel Braided Flexible High-quality Refined Copper Joints Strong Torque Resistance represents a premium solution engineered specifically for commercial and residential water supply applications. This advanced plumbing hose combines cutting-edge materials technology with precision manufacturing to create a product that exceeds industry standards for flexibility, strength, and longevity. Whether serving the needs of professional contractors, facility managers, or equipment manufacturers, this braided flexible hose delivers consistent performance across diverse installation environments.

Product Overview

The FANKSI kitchen water plumbing hose showcases sophisticated engineering through its multi-layered construction design. The foundation consists of a high-grade inner tube that maintains water purity while resisting chemical degradation and temperature fluctuations. Surrounding this core, the stainless steel braided reinforcement provides exceptional burst resistance and maintains structural integrity under varying pressure conditions. The refined copper joints represent precision-machined components that ensure leak-proof connections while offering superior corrosion resistance compared to standard fittings.

This flexible plumbing solution addresses the critical requirements of modern water distribution systems where space constraints, installation complexity, and performance demands create unique challenges. The combination of stainless steel braiding and refined copper joints creates a hybrid construction that maximizes both mechanical strength and chemical compatibility across diverse water quality conditions.

Features & Benefits

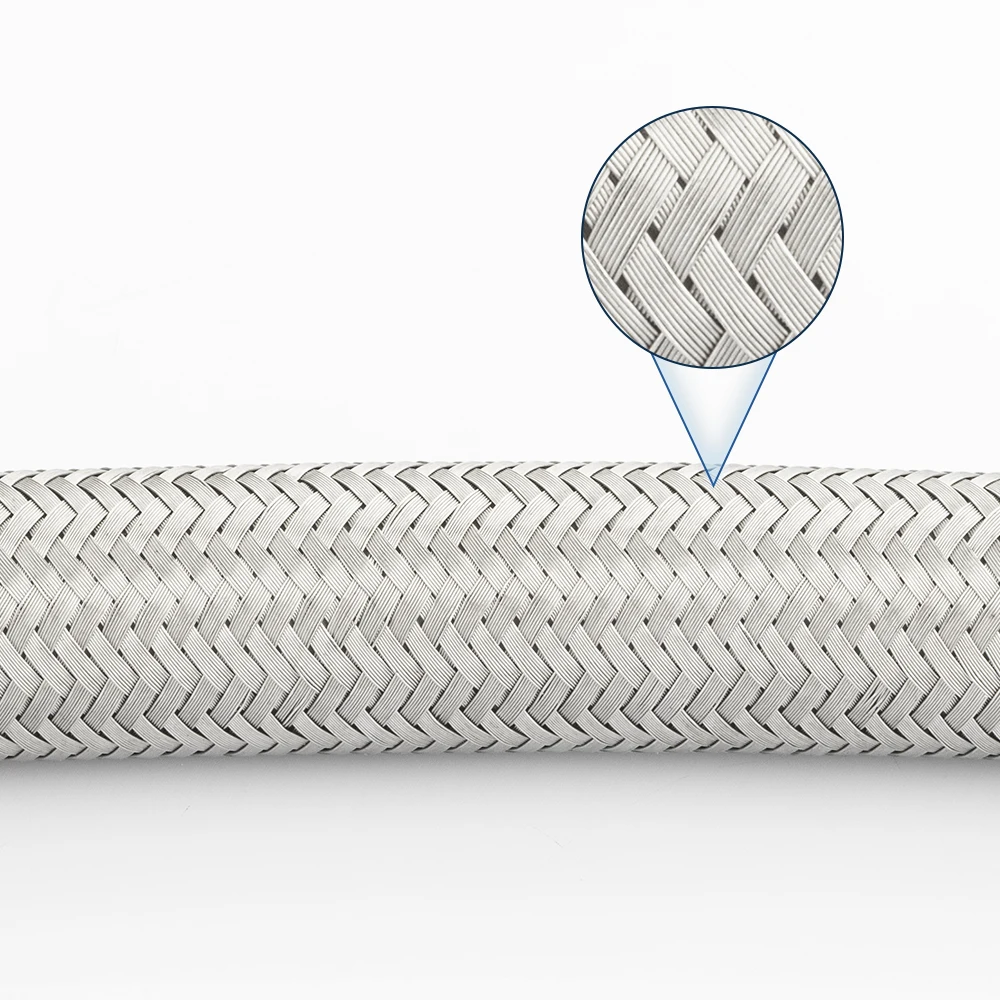

Advanced Stainless Steel Braided Construction

The stainless steel braided exterior of this kitchen water plumbing hose provides exceptional mechanical protection and pressure resistance. The braided design distributes stress evenly across the hose surface, preventing localized wear and extending operational lifespan significantly beyond conventional rubber or plastic alternatives. This construction methodology also enhances flexibility while maintaining structural integrity, allowing for complex routing configurations without compromising performance.

Refined Copper Joint Technology

The refined copper joints incorporated into the FANKSI plumbing hose represent precision-engineered connection points that deliver superior sealing performance and corrosion resistance. These joints undergo specialized refinement processes that enhance their mechanical properties and chemical stability. The copper material naturally resists bacterial growth and maintains excellent thermal conductivity, making these joints particularly suitable for hot water applications and food service environments.

Strong Torque Resistance Properties

The strong torque resistance characteristics of this plumbing hose ensure reliable performance in installations where rotational stress and mechanical movement are common. This feature proves particularly valuable in commercial kitchen environments, industrial facilities, and residential applications where equipment vibration or thermal expansion could otherwise compromise connection integrity. The torque resistance properties also facilitate easier installation and maintenance procedures.

Applications & Use Cases

Commercial kitchen installations represent a primary application area for the FANKSI Kitchen Water Plumbing Hose Stainless Steel Braided Flexible High-quality Refined Copper Joints Strong Torque Resistance. Restaurant equipment, food processing facilities, and institutional cafeterias benefit from the hose's ability to withstand frequent cleaning cycles, temperature variations, and the chemical exposure common in food service environments. The stainless steel construction ensures compliance with health department regulations while the refined copper joints provide reliable connections for high-demand equipment.

Residential plumbing applications also benefit significantly from this advanced hose design. Under-sink installations, appliance connections, and bathroom fixtures gain enhanced reliability and longevity when connected with these premium hoses. The flexible nature of the braided construction simplifies installation in tight spaces while the strong torque resistance prevents connection loosening due to appliance operation or building settling.

Industrial water supply systems represent another key application area where the superior materials and construction of this plumbing hose provide measurable advantages. Manufacturing facilities, laboratories, and processing plants require water distribution components that maintain consistent performance under demanding operational conditions. The combination of stainless steel braiding and refined copper joints ensures reliable service in environments where water quality, pressure consistency, and system uptime are critical factors.

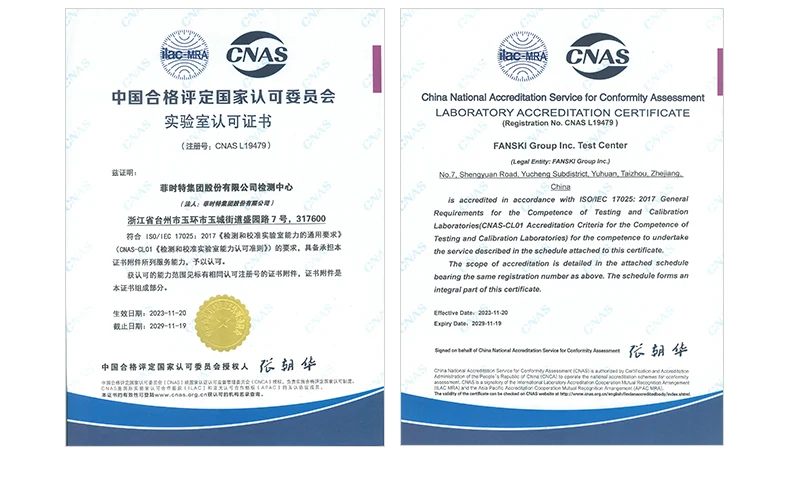

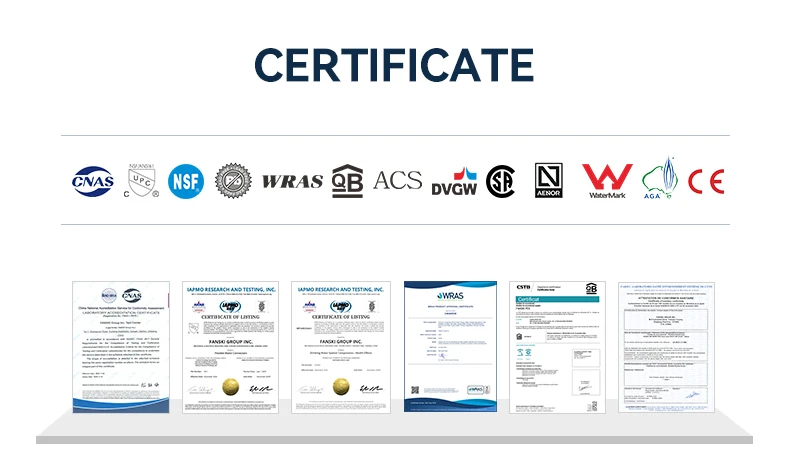

Quality Control & Compliance

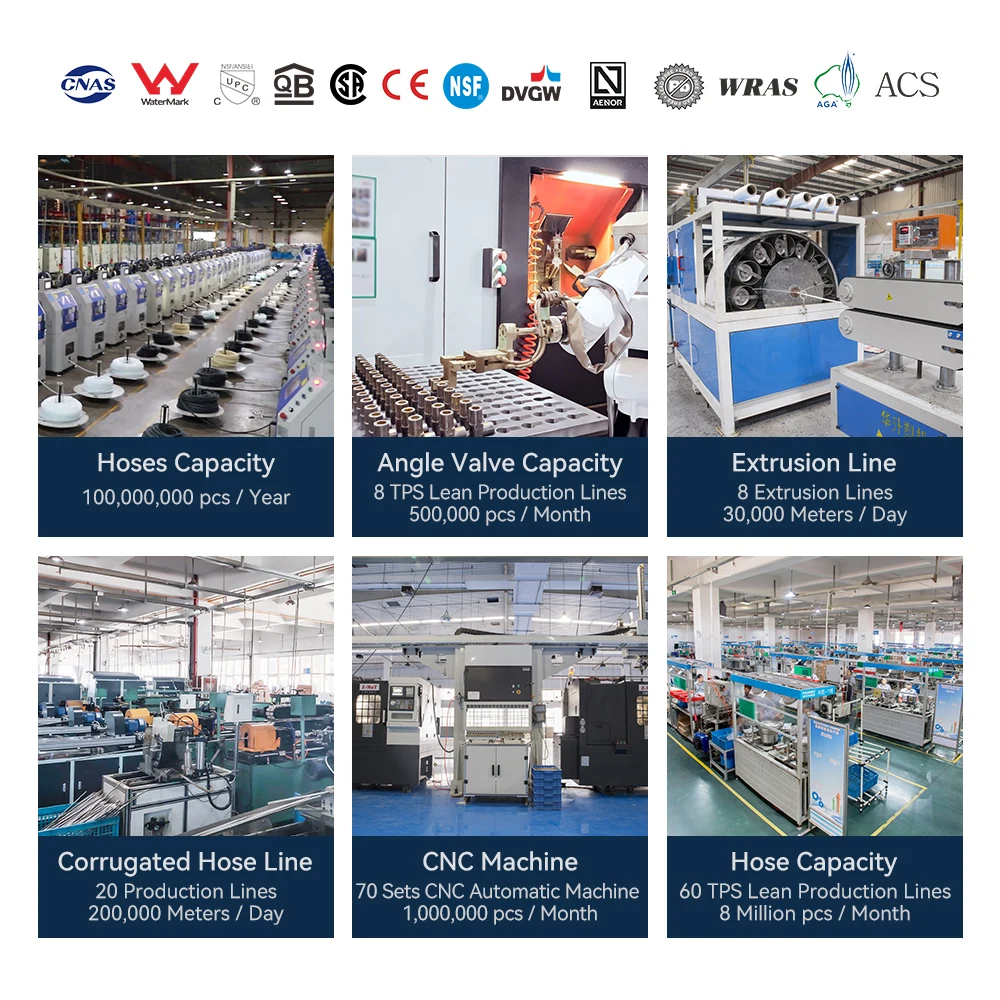

Manufacturing excellence forms the foundation of every FANKSI kitchen water plumbing hose through comprehensive quality control processes that verify material integrity, dimensional accuracy, and performance characteristics. Each hose undergoes rigorous testing protocols that validate pressure resistance, flexibility parameters, and joint sealing effectiveness. The stainless steel braiding receives particular attention during inspection to ensure uniform coverage, appropriate tension, and proper integration with the underlying hose structure.

The refined copper joints undergo specialized quality verification procedures that confirm dimensional precision, surface finish quality, and metallurgical properties. These inspections ensure that each joint meets the exacting standards required for leak-proof connections and long-term corrosion resistance. Advanced testing equipment validates the strong torque resistance properties under simulated installation and operational conditions.

International compliance standards guide the manufacturing process, ensuring that the finished products meet or exceed regional requirements for plumbing components, water safety, and material compatibility. This comprehensive approach to quality assurance provides confidence for distributors, contractors, and end users who require reliable performance from their plumbing infrastructure investments.

Customization & Branding Options

Professional distributors and equipment manufacturers can access comprehensive customization capabilities that adapt the FANKSI plumbing hose to specific market requirements and application needs. Length variations accommodate diverse installation scenarios, while specialized fitting configurations ensure compatibility with various equipment types and connection standards. The flexible design parameters allow for modifications that address unique pressure requirements, temperature ranges, or chemical compatibility specifications.

Branding customization options enable distributors to enhance their market presence through personalized product identification and packaging solutions. These options include custom labeling, specialized packaging formats, and documentation customization that aligns with distributor marketing strategies and customer expectations. Such flexibility proves particularly valuable for companies serving specialized market segments or geographic regions with specific regulatory requirements.

Technical customization extends to specialized materials or construction variations that address unique application challenges. Whether serving as an OEM supplier for equipment manufacturers or supporting specialized installation requirements, the manufacturing flexibility ensures that customer-specific needs receive appropriate attention and professional solutions.

Packaging & Logistics Support

Professional packaging solutions protect the integrity of each FANKSI Kitchen Water Plumbing Hose Stainless Steel Braided Flexible High-quality Refined Copper Joints Strong Torque Resistance throughout the distribution chain. Specialized packaging formats prevent damage to the stainless steel braiding and copper joints while facilitating efficient storage and handling procedures. The packaging design considers the flexible nature of the product while providing adequate protection against environmental factors and mechanical stress during shipping.

Logistics optimization features include packaging configurations that maximize shipping efficiency while minimizing handling complexity. These solutions prove particularly valuable for international distributors who require reliable product protection across extended supply chains. The packaging approach also supports inventory management through clear product identification and organized presentation formats that facilitate warehouse operations and order fulfillment procedures.

Documentation integration ensures that technical specifications, installation guidelines, and compliance certifications accompany each shipment appropriately. This comprehensive approach to logistics support reduces distribution complexity while ensuring that end users receive complete product information and installation guidance.

Why Choose Us

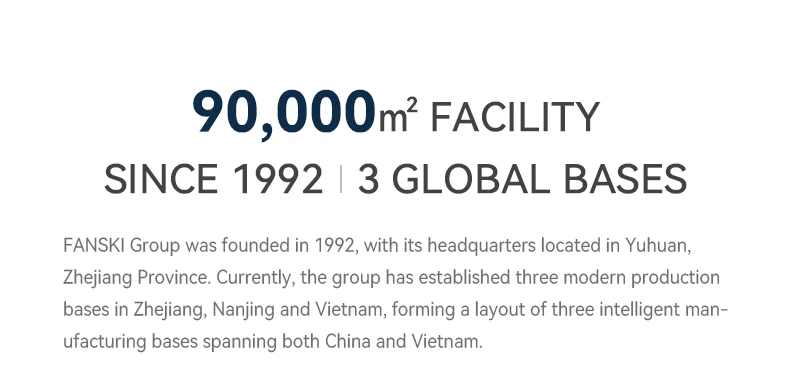

Our extensive experience serving international markets across multiple industries has established us as a trusted metal packaging manufacturer and supplier of premium plumbing components. This expertise translates into deep understanding of diverse market requirements, regulatory environments, and application challenges that our customers face. Our manufacturing capabilities combine advanced production technology with rigorous quality control processes that ensure consistent product excellence across all product lines.

As a recognized custom tin box supplier and OEM tin packaging solutions provider, we bring the same commitment to precision engineering and quality excellence to our plumbing component manufacturing. This cross-industry expertise enables innovative approaches to product design, materials selection, and manufacturing processes that benefit our plumbing customers through enhanced product performance and reliability.

Our global supply chain capabilities and established partnerships with metal packaging suppliers worldwide ensure reliable availability and consistent quality regardless of order size or delivery destination. This comprehensive infrastructure supports both established distributors and emerging market participants with professional service and dependable product supply.

Conclusion

The FANKSI Kitchen Water Plumbing Hose Stainless Steel Braided Flexible High-quality Refined Copper Joints Strong Torque Resistance represents the convergence of advanced materials technology, precision manufacturing, and practical application expertise. This premium plumbing component delivers exceptional value through its combination of durability, flexibility, and reliable performance across diverse installation environments. Whether serving commercial kitchens, residential applications, or industrial water systems, this braided flexible hose provides the reliability and longevity that professional installations demand. The sophisticated engineering of the stainless steel braiding, refined copper joints, and strong torque resistance properties ensures that this product will continue delivering superior performance long after installation, making it an intelligent investment for contractors, facility managers, and equipment manufacturers who prioritize quality and reliability in their plumbing infrastructure.