Introduction

Professional plumbing installations demand superior quality components that deliver reliable performance under demanding conditions. The FANKSI Water Plumbing Hose Stainless Steel Braided Hoses High-quality Refined Copper Joints Strong Torque Resistance represents a premium solution engineered for commercial and industrial applications. These specialized hoses combine advanced materials engineering with precision manufacturing to create a product that meets the exacting standards of professional contractors, facility managers, and industrial maintenance teams worldwide.

Modern plumbing systems require flexible connections that can withstand high pressure, temperature variations, and constant mechanical stress while maintaining leak-free operation. Traditional rubber hoses often fail to meet these demanding requirements, leading to costly maintenance issues and system downtime. FANKSI has addressed these challenges by developing a sophisticated braided hose design that incorporates stainless steel reinforcement and premium copper joint construction for exceptional durability and performance.

Product Overview

The FANKSI Water Plumbing Hose Stainless Steel Braided Hoses High-quality Refined Copper Joints Strong Torque Resistance features a multi-layer construction designed for optimal performance in diverse plumbing applications. The inner core utilizes food-grade materials that ensure water purity while providing excellent chemical resistance. This inner layer is reinforced with multiple stainless steel braided layers that provide exceptional burst strength and flexibility without compromising the hose's ability to maintain its shape under pressure.

The refined copper joints represent a significant advancement in hose connection technology. These precision-machined components feature enhanced threading designs that distribute stress evenly across the connection point, preventing the loosening and leakage issues commonly associated with standard fittings. The copper alloy composition provides superior corrosion resistance while maintaining the mechanical properties necessary for reliable long-term performance in various water quality conditions.

Each hose undergoes rigorous testing throughout the manufacturing process to ensure consistent quality and performance. The stainless steel braiding utilizes marine-grade materials that resist corrosion even in harsh environments, making these hoses suitable for both indoor and outdoor installations. The sophisticated manufacturing process ensures uniform wall thickness and consistent performance characteristics across the entire product line.

Features & Benefits

Advanced Stainless Steel Braided Construction

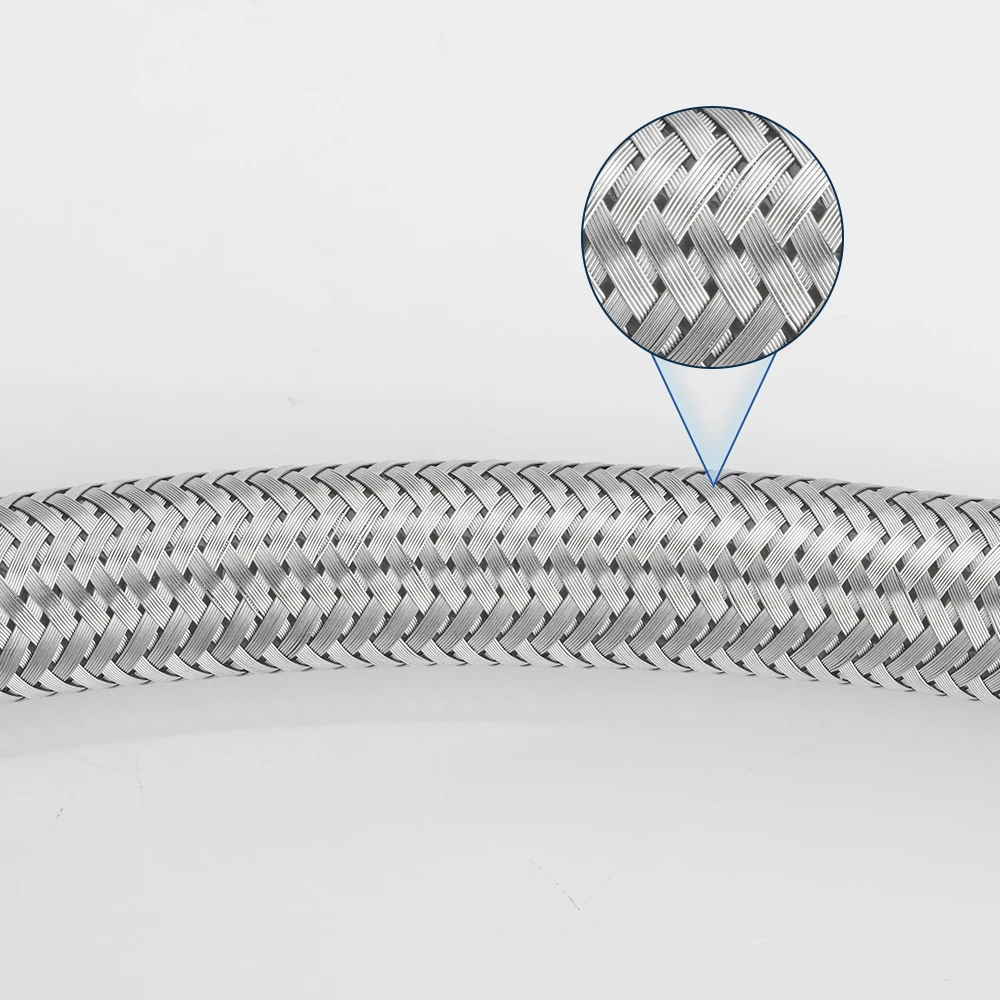

The stainless steel braided reinforcement system represents the cornerstone of the FANKSI Water Plumbing Hose design philosophy. Multiple layers of precision-woven stainless steel wire provide exceptional burst resistance while maintaining the flexibility necessary for complex installation configurations. This braided construction distributes stress evenly across the hose surface, preventing localized failure points that can lead to catastrophic system failures.

The braiding pattern utilizes advanced weaving techniques that maximize coverage while minimizing weight. This approach ensures that the hose remains manageable during installation while providing superior protection against external damage. The stainless steel material selection focuses on alloys that provide optimal corrosion resistance without sacrificing mechanical properties, ensuring long-term performance in diverse environmental conditions.

Premium Refined Copper Joint Technology

The refined copper joints featured in these hoses represent a significant advancement over standard brass or chrome-plated fittings. The precision machining process ensures perfect thread geometry and surface finish, creating connections that seal reliably without requiring excessive torque. This characteristic is particularly important in applications where repeated connection and disconnection cycles are common.

The copper alloy composition provides natural antimicrobial properties while maintaining excellent thermal conductivity. This combination helps prevent bacterial growth within the connection points while efficiently dissipating heat generated by water flow. The refined surface treatment enhances the appearance while providing additional protection against environmental factors that could compromise joint integrity.

Exceptional Torque Resistance Performance

Strong torque resistance capabilities distinguish these hoses from conventional flexible connections. The integrated design approach ensures that rotational forces applied to the joints do not transfer to the hose body, preventing twisting and kinking that can restrict flow or damage the internal structure. This feature is particularly valuable in installations where space constraints require complex routing configurations.

The torque resistance system incorporates specialized internal components that allow the hose to accommodate angular misalignment without generating stress concentrations. This capability extends service life while maintaining optimal flow characteristics throughout the operational range. Professional installers appreciate this feature as it simplifies installation procedures and reduces the risk of installation-related failures.

Applications & Use Cases

Commercial kitchen installations represent one of the primary applications for FANKSI Water Plumbing Hose Stainless Steel Braided Hoses High-quality Refined Copper Joints Strong Torque Resistance. The food service industry demands connections that maintain water purity while withstanding frequent cleaning cycles and temperature variations. These hoses excel in connecting commercial dishwashers, ice machines, and beverage dispensing equipment where reliability and hygiene are paramount concerns.

Industrial manufacturing facilities utilize these hoses for process water connections, cooling system installations, and equipment supply lines. The robust construction withstands the vibration and thermal cycling common in manufacturing environments while maintaining leak-free operation. The stainless steel braiding provides excellent protection against mechanical damage from nearby machinery or foot traffic, reducing maintenance requirements and system downtime.

Healthcare facilities require plumbing connections that meet stringent hygiene standards while providing reliable service in critical applications. These hoses serve effectively in laboratory equipment connections, sterilizer supply lines, and specialized medical equipment installations. The antimicrobial properties of the copper joints combined with the corrosion-resistant stainless steel construction make them ideal for environments where contamination prevention is essential.

Residential and commercial water heater installations benefit from the thermal performance and durability of these specialized hoses. The ability to accommodate thermal expansion and contraction without developing leaks or restricting flow makes them particularly suitable for high-efficiency water heating systems. The refined copper joints maintain their sealing properties even under repeated thermal cycling conditions.

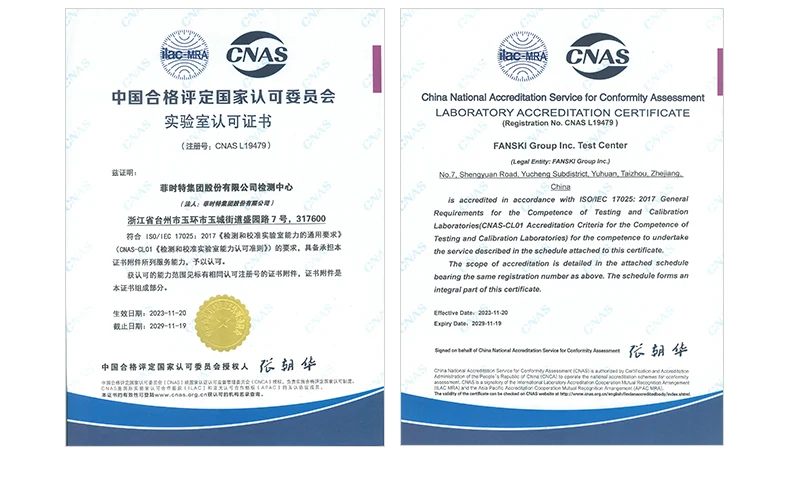

Quality Control & Compliance

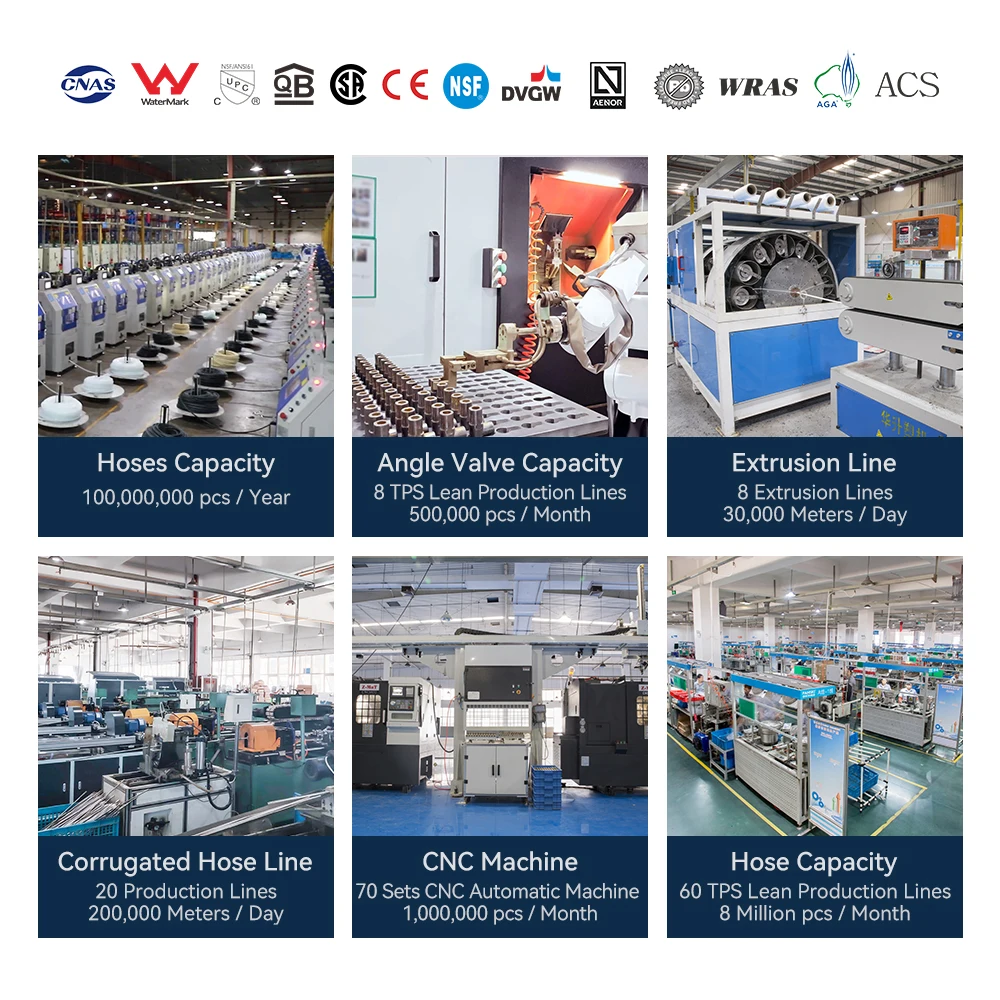

Manufacturing excellence drives every aspect of the FANKSI production process, ensuring that each Water Plumbing Hose Stainless Steel Braided Hoses High-quality Refined Copper Joints Strong Torque Resistance meets or exceeds international quality standards. The comprehensive quality management system incorporates multiple inspection points throughout the manufacturing process, from raw material verification through final product testing.

Raw material sourcing focuses on suppliers who maintain certified quality systems and can provide complete traceability documentation. The stainless steel wire used in the braiding process undergoes chemical composition analysis and mechanical property testing to ensure consistency with design specifications. Similarly, the copper alloys used for joint manufacturing are verified for composition, mechanical properties, and surface quality before entering the production process.

Final product testing includes pressure testing, leak detection, and durability cycling to verify performance under simulated service conditions. Each production batch undergoes statistical sampling procedures to ensure consistent quality across the entire production run. The testing protocols incorporate accelerated aging procedures that simulate extended service life, providing confidence in long-term performance predictions.

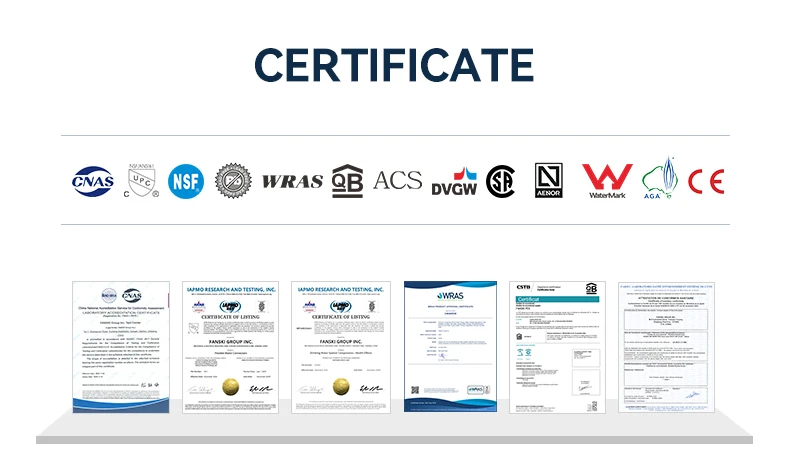

International compliance standards guide the design and manufacturing process, ensuring compatibility with global plumbing codes and regulations. The materials selection and construction methods align with requirements for potable water applications, food service installations, and commercial building systems. Comprehensive documentation supports certification processes required for various international markets.

Customization & Branding Options

Understanding that different markets and applications have unique requirements, FANKSI offers comprehensive customization capabilities for the Water Plumbing Hose Stainless Steel Braided Hoses High-quality Refined Copper Joints Strong Torque Resistance product line. Length variations accommodate specific installation requirements while maintaining the same high-quality construction standards across all configurations. Custom threading options ensure compatibility with various international plumbing standards and specialized equipment connections.

Surface treatment options provide additional customization possibilities for specific environmental conditions or aesthetic requirements. Enhanced corrosion protection treatments extend service life in aggressive environments, while specialized finishes can provide improved appearance for visible installations. The flexible manufacturing process accommodates these modifications without compromising the fundamental performance characteristics of the base design.

Private labeling and packaging customization services support distributors and equipment manufacturers who require branded products for their market channels. Custom packaging solutions protect the products during shipping while providing professional presentation that enhances market acceptance. The experienced design team works closely with clients to develop packaging solutions that meet both protective and marketing requirements.

Technical specification modifications address unique application requirements without requiring complete product redesign. The engineering team evaluates custom requirements and develops solutions that maintain the proven performance characteristics while meeting specific customer needs. This collaborative approach ensures that customized products deliver the same reliability and performance as standard configurations.

Packaging & Logistics Support

Professional packaging systems protect FANKSI Water Plumbing Hose Stainless Steel Braided Hoses High-quality Refined Copper Joints Strong Torque Resistance products throughout the distribution chain while facilitating efficient handling and storage. Individual hose protection prevents surface damage and contamination during shipping, while bulk packaging options optimize shipping efficiency for large orders. The packaging materials selection focuses on environmental sustainability without compromising protective performance.

Warehouse-friendly packaging configurations facilitate efficient inventory management and order fulfillment processes. Standardized packaging dimensions maximize shipping container utilization while simplifying handling procedures. Clear product identification and traceability marking support inventory control systems and quality assurance procedures throughout the distribution network.

International shipping compliance represents a critical aspect of the packaging system design. All packaging materials and labeling meet international shipping regulations while providing the documentation necessary for customs clearance procedures. The logistics team maintains current knowledge of international shipping requirements and adjusts packaging specifications as regulations evolve.

Just-in-time delivery capabilities support customers who require flexible inventory management solutions. The efficient production planning system accommodates varying demand patterns while maintaining consistent product availability. Strategic warehouse locations reduce shipping times and costs while providing local inventory support for regional distributors.

Why Choose Us

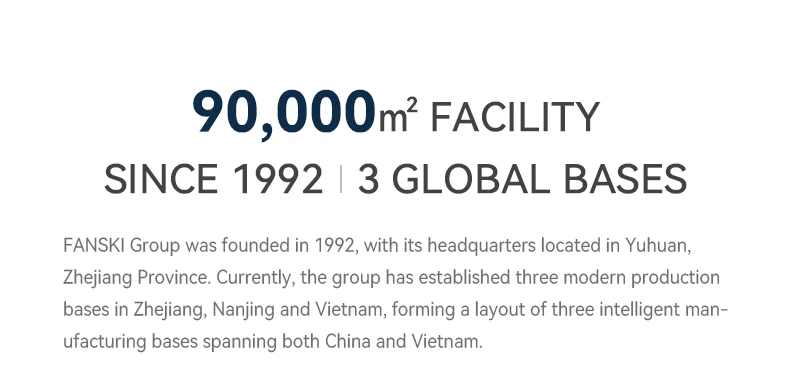

FANKSI brings extensive experience in precision manufacturing and international market development to every product we deliver. Our commitment to engineering excellence has established strong relationships with professional contractors, equipment manufacturers, and distributors across multiple continents. This global perspective ensures that our products meet the diverse requirements of international markets while maintaining consistent quality standards.

As a recognized metal packaging manufacturer and custom solutions provider, we understand the importance of reliable supply chain partnerships in today's competitive marketplace. Our OEM capabilities extend beyond standard products to include specialized configurations that meet unique application requirements. This flexibility, combined with our proven track record of quality delivery, makes us a preferred supplier for companies seeking reliable long-term partnerships.

The technical expertise developed through years of collaboration with leading industry professionals enables us to anticipate market trends and develop products that address evolving customer needs. Our investment in advanced manufacturing technologies and quality control systems ensures that we can meet the increasing demands for performance, reliability, and environmental compliance.

Continuous improvement initiatives drive our product development process, incorporating customer feedback and market research to enhance existing products while developing innovative solutions for emerging applications. This customer-focused approach has resulted in strong relationships with distributors and end users who value reliable products backed by responsive technical support.

Conclusion

The FANKSI Water Plumbing Hose Stainless Steel Braided Hoses High-quality Refined Copper Joints Strong Torque Resistance represents a superior solution for professional plumbing applications requiring exceptional reliability and performance. The advanced materials engineering, precision manufacturing, and comprehensive quality control systems combine to create a product that exceeds the expectations of demanding commercial and industrial applications. The stainless steel braided construction provides exceptional durability while the refined copper joints ensure leak-free connections that maintain their integrity throughout extended service cycles. These features, combined with strong torque resistance capabilities, make these hoses an excellent choice for installations where system reliability is critical to operational success.