Introduction

Professional plumbing installations demand reliable connection solutions that combine durability, flexibility, and superior performance under demanding conditions. The FANSKI Stainless Steel Braided EPDM Inner Tube Flexible Bathroom Hose represents the pinnacle of modern flexible hose technology, engineered specifically for commercial and residential bathroom applications where reliability cannot be compromised. This advanced flexible hose solution incorporates premium materials and precision manufacturing to deliver exceptional service life while maintaining optimal flow characteristics and pressure resistance capabilities.

Product Overview

The FANSKI flexible bathroom hose features a sophisticated multi-layer construction that balances strength, flexibility, and longevity in demanding plumbing environments. At its core lies a high-grade EPDM inner tube that provides excellent chemical resistance and maintains structural integrity across a wide temperature range. The outer braided stainless steel reinforcement layer delivers exceptional burst pressure resistance while allowing the hose to maintain flexibility during installation and operation.

This professional-grade flexible hose incorporates modern engineering principles to address common challenges faced by plumbing contractors and facility managers. The innovative design eliminates many of the reliability concerns associated with traditional rubber hoses while providing the flexibility required for complex routing scenarios. The balanced construction ensures consistent performance characteristics throughout the product's operational lifespan, making it an ideal choice for both new installations and replacement applications.

Features & Benefits

Advanced Material Technology

The EPDM inner tube construction provides superior resistance to hot water, chemicals, and ozone exposure compared to standard rubber alternatives. This synthetic rubber compound maintains its elastic properties across temperature extremes while resisting degradation from common bathroom cleaning chemicals and water treatment additives. The material's inherent stability ensures consistent flow characteristics and prevents the development of internal deposits that can reduce performance over time.

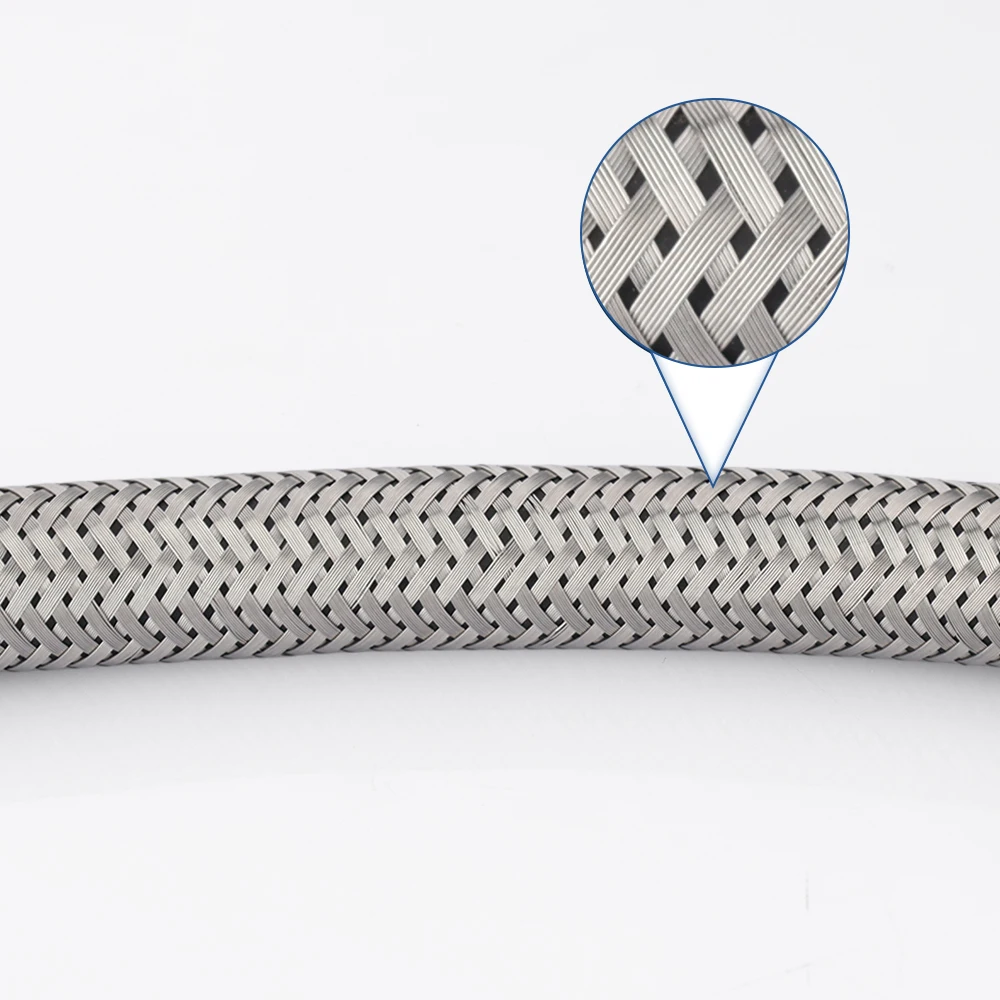

Stainless Steel Braided Reinforcement

The external stainless steel braided layer serves multiple critical functions beyond pressure resistance. This metallic reinforcement provides excellent protection against external damage while maintaining the hose's flexibility during installation. The braided construction distributes stress evenly across the hose surface, preventing localized wear patterns that commonly develop in high-flexing applications. Additionally, the stainless steel material resists corrosion and maintains its appearance throughout the product's service life.

Temperature and Pressure Performance

Engineering specifications establish this flexible hose as suitable for demanding commercial applications where consistent performance under varying conditions is essential. The robust construction handles significant pressure variations without compromising structural integrity or flow characteristics. Temperature resistance capabilities ensure reliable operation across the full range of typical hot water system temperatures, providing peace of mind for installers and end users alike.

Applications & Use Cases

Commercial bathroom installations represent the primary application environment for this professional-grade flexible hose system. Hotels, office buildings, healthcare facilities, and educational institutions benefit from the enhanced reliability and extended service life provided by the advanced material construction. The flexible design facilitates installation in tight spaces and complex routing scenarios commonly encountered in modern commercial construction projects.

Residential applications also benefit significantly from the superior performance characteristics of this flexible hose solution. High-end bathroom installations, luxury homes, and residential developments where long-term reliability is prioritized find this product particularly well-suited to their requirements. The modern aesthetic complements contemporary bathroom designs while the robust construction ensures years of trouble-free operation.

Renovation and retrofit projects present another important application category where the flexibility and reliability of this hose system provide distinct advantages. The ability to route around existing infrastructure while maintaining full performance capabilities simplifies installation procedures and reduces project complexity. Maintenance professionals appreciate the predictable performance characteristics and extended replacement intervals that result from the superior material selection and construction quality.

Quality Control & Compliance

Manufacturing processes incorporate comprehensive quality control measures throughout every stage of production to ensure consistent product performance and reliability. Raw material inspection procedures verify that all components meet stringent specifications for chemical composition, mechanical properties, and dimensional accuracy. Advanced testing protocols validate pressure resistance, temperature stability, and fatigue resistance under accelerated aging conditions that simulate years of actual service.

International compliance standards guide the design and manufacturing processes, ensuring compatibility with global plumbing codes and installation requirements. The comprehensive testing regimen includes burst pressure evaluation, temperature cycling, chemical resistance assessment, and long-term durability validation. These rigorous quality assurance measures provide confidence for specifiers, installers, and end users across diverse market segments and geographic regions.

Traceability systems maintain detailed records of material sources, production parameters, and quality test results for each manufactured batch. This systematic approach enables rapid identification and resolution of any quality concerns while supporting continuous improvement initiatives. The documented quality history provides valuable data for product optimization and helps maintain the consistently high performance standards expected by professional users.

Customization & Branding Options

Flexible manufacturing capabilities accommodate specific customer requirements for length variations, end fitting configurations, and specialized material formulations. Custom packaging manufacturer services support private labeling requirements for distributors and contractors who value brand consistency across their product offerings. The adaptable production processes enable efficient customization without compromising the fundamental performance characteristics that define this product line.

OEM tin packaging solutions provide enhanced product presentation and protection during storage and transportation. Custom packaging designs can incorporate distributor branding, installation instructions, and technical specifications tailored to specific market requirements. The comprehensive customization capabilities extend beyond packaging to include specialized testing protocols and certification documentation required for particular applications or geographic markets.

Engineering support services assist customers in developing application-specific variations that address unique installation challenges or performance requirements. This collaborative approach leverages extensive material science expertise and manufacturing flexibility to create solutions that optimize performance for specific use cases while maintaining compliance with relevant industry standards.

Packaging & Logistics Support

Comprehensive packaging solutions protect product integrity throughout the distribution chain while optimizing shipping efficiency and storage requirements. Protective packaging materials prevent damage during handling and transportation while compact designs minimize storage space requirements for distributors and contractors. The systematic packaging approach ensures products arrive in perfect condition regardless of shipping distance or handling procedures.

Logistics coordination services streamline the supply chain process for international distributors and large-volume customers. Flexible shipping schedules accommodate varying demand patterns while inventory management support helps distributors optimize stock levels and reduce carrying costs. The comprehensive logistics framework ensures reliable product availability while minimizing total supply chain costs for all participants.

Documentation and labeling systems provide clear product identification and technical information throughout the distribution process. Multilingual labeling options support international market requirements while detailed technical documentation facilitates proper installation and maintenance procedures. The comprehensive information package ensures that all stakeholders have access to the technical data required for successful product application and customer satisfaction.

Why Choose Us

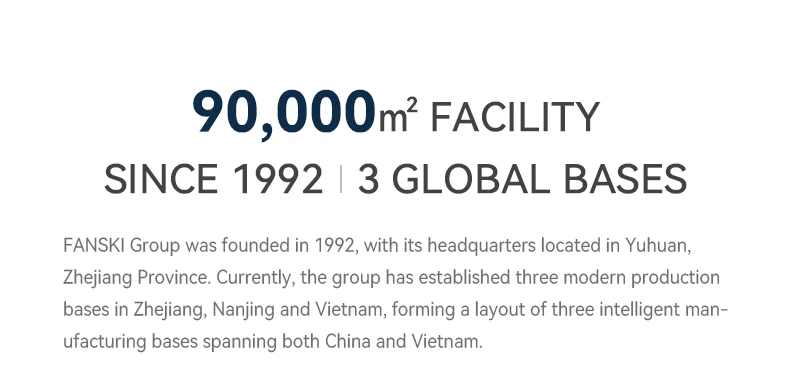

Our organization brings decades of experience in developing and manufacturing premium flexible hose solutions for demanding industrial and commercial applications worldwide. This extensive background in engineered hose systems provides the technical expertise and manufacturing capabilities required to produce consistently superior products that exceed customer expectations. International market presence across multiple continents demonstrates our commitment to serving diverse customer bases with reliable, high-quality solutions.

As a recognized metal packaging supplier and custom tin box supplier, we understand the importance of comprehensive product presentation and protection throughout the supply chain. This multi-industry expertise enables us to provide complete solutions that address not only the core product requirements but also the packaging, documentation, and logistics support that professional customers require for successful market deployment.

Continuous investment in advanced manufacturing technology and quality control systems ensures that our products maintain their position at the forefront of industry performance standards. Collaborative relationships with customers across diverse market segments provide valuable feedback that drives ongoing product development and improvement initiatives. This customer-focused approach combined with technical excellence creates sustainable competitive advantages that benefit all stakeholders in the supply chain.

Conclusion

The FANSKI Stainless Steel Braided EPDM Inner Tube Flexible Bathroom Hose represents a superior solution for professional plumbing applications where reliability, durability, and performance cannot be compromised. The advanced material technology, robust construction, and comprehensive quality assurance measures combine to deliver exceptional value for commercial and residential installations. Whether specified for new construction projects, renovation applications, or maintenance replacement requirements, this flexible hose system provides the performance characteristics and service life that professional users demand. The combination of technical excellence, manufacturing quality, and comprehensive support services establishes this product as the preferred choice for discerning customers who prioritize long-term reliability and operational success in their plumbing infrastructure investments.

Product Name |

Stainless Steel Braided Hose |

Specification |

φ14 F1/2*F1/2 |

Nominal Diameter |

DN10 |

Material of Inner Tube |

EPDM |

Material of End |

Refined Brass |

Material of Wire |

SUS304 |

Working Pressure |

1.0Mpa |

Max Temperature |

90℃ |

Nut Torque |

60N.m |

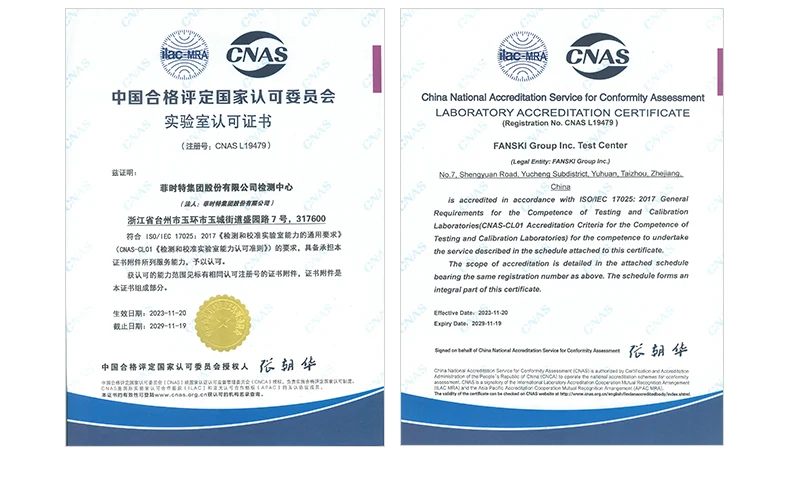

Certificate |

DVGW |

WARRANTY |

20 Years |

LOSS COVERAGE/CASE/USD |

2 Million |

Logo |

Customized logo welcomed |

Packing |

Standard export package or customized |

A:Yes. we're professional manufacture in China,and have been in this field for more

than 30 years.

Q:What payment terms do you support?

A: T/T,L/C,DP,DDU,DDP etc are available, and for T/T we accept 30% deposit in advance,70% balance against copy of B/L.

A:In-stock items typically ship within a week. Out-of-stock items usually ship within 4-6 weeks, while custom orders depend on your specific design requirements.

Q:How long is your delivery time for the item without stock?

A:30-40 days after receiving deposit.

Q:ls it possible to get samples from your factory?

A:Yes. Free samples will be sent if needed, but the freight can be negotiated or chargeable, it will be refunded after

confirmation of the order.

Q:Can l use my own logo or design on your products?

A:Absolutely yes. We offer OEM/ODM services to customize products with your logo or design.

Q:Do you operate your own factories?

A:Yes, we have factories in Zhejiang and Vietnam. We also work closely with other reliable manufacturers to meet different needs.You' re welcome to visit us.

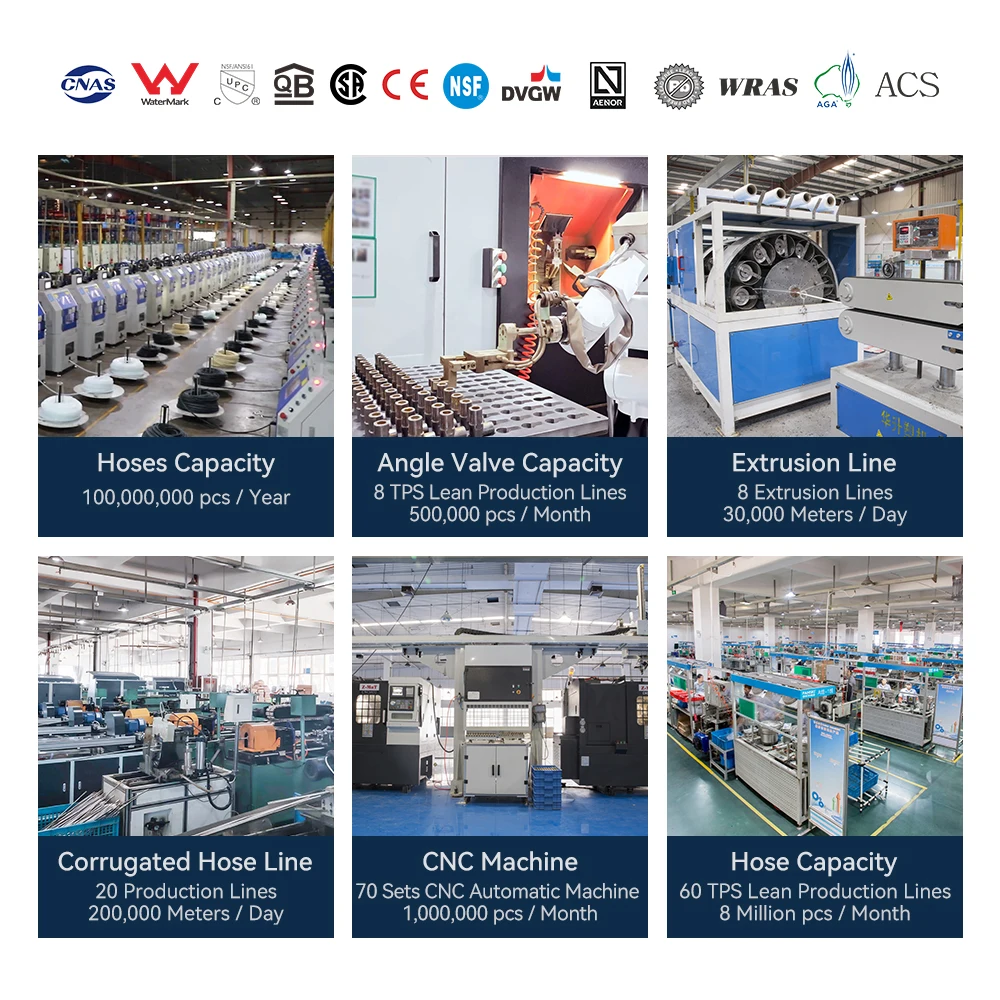

Q:What is your production capacity?

A:For the products of flexible hose,we can make 8 million pieces a month and for the angle valve,we can make 1.6 million pieces a month. We also maintain strong partnerships with other suppliers to ensure timely and reliable deliveries.

Q:How do you choose your suppliers?

A:We rigorously select suppliers based on their performance in domestic projects focusing on their production capacity, delivery reliability, and quality control. Our own quality team oversees this process.

A:Yes, we provide after-sales support with warranties ranging from 3 to 20 years depending on the product. Please contact us for more information.

Q:Do you accept small orders?

A:Yes, we welcome the orders that it may meet our requirement of MOQ for different products. We are committed to providing excellent service to every customer.