Introduction

The plumbing industry continues to evolve with advanced materials and innovative engineering solutions that address both functionality and longevity concerns. Professional contractors, distributors, and facility managers increasingly seek reliable flexible hose systems that combine superior durability with modern aesthetic appeal. The Modern Inner EPDM Tube Nylon Fitting Wire SUS304 Stainless Steel Braided Flexible Bathroom Toilet Hose 10+ Year Warranty 10 BAR represents a breakthrough in flexible plumbing technology, engineered to meet demanding commercial and residential applications while maintaining consistent performance under varying pressure conditions.

This advanced flexible hose system incorporates multiple layers of premium materials, each carefully selected to optimize specific performance characteristics. The integration of EPDM inner tubing with stainless steel braiding creates a robust yet flexible solution that addresses common challenges in bathroom and toilet installations. Modern plumbing professionals recognize the importance of selecting components that not only meet immediate installation requirements but also provide long-term reliability and reduced maintenance costs.

Product Overview

The Modern Inner EPDM Tube Nylon Fitting Wire SUS304 Stainless Steel Braided Flexible Bathroom Toilet Hose 10+ Year Warranty 10 BAR features a sophisticated multi-layer construction designed to optimize both performance and aesthetics. The inner EPDM tube provides exceptional chemical resistance and maintains flexibility across a wide temperature range, while the outer stainless steel braiding delivers structural integrity and pressure resistance. This combination ensures consistent water flow while protecting against common failure modes that affect traditional flexible hose systems.

The nylon fitting components incorporate advanced molding techniques that create secure, leak-resistant connections with standard plumbing fixtures. These fittings feature precision-engineered threads and sealing surfaces that maintain tight connections even under thermal cycling conditions. The SUS304 stainless steel braiding offers superior corrosion resistance compared to standard steel alternatives, making this hose particularly suitable for humid bathroom environments where long-term durability is essential.

Contemporary bathroom design increasingly emphasizes clean lines and premium finishes, and this flexible hose system complements modern aesthetic preferences while delivering professional-grade performance. The stainless steel exterior provides an attractive metallic finish that coordinates well with contemporary fixtures and fittings, eliminating the need to conceal the hose within walls or cabinetry in many installations.

Features & Benefits

Advanced Material Engineering

The EPDM inner tube represents a significant advancement over traditional rubber compounds, offering enhanced resistance to chlorinated water, temperature extremes, and chemical additives commonly found in municipal water systems. This synthetic rubber compound maintains its flexibility and sealing properties over extended service periods, reducing the likelihood of internal degradation that can lead to reduced flow rates or contamination concerns.

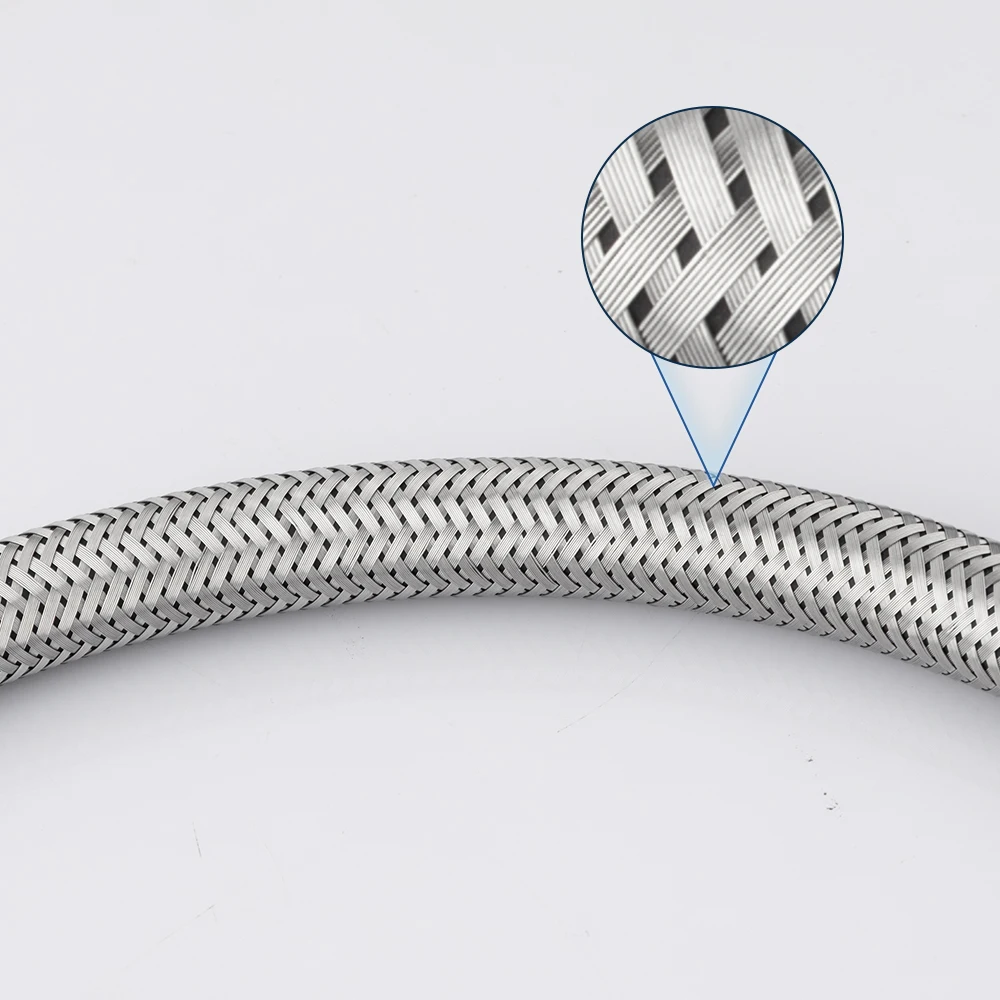

The SUS304 stainless steel braiding provides exceptional tensile strength while maintaining the flexibility necessary for complex routing configurations. This grade of stainless steel offers superior corrosion resistance in bathroom environments, where exposure to moisture, cleaning chemicals, and temperature variations can quickly degrade inferior materials. The braided construction distributes stress evenly across the hose length, preventing localized failure points that commonly occur in less sophisticated designs.

Extended Service Life

The Modern Inner EPDM Tube Nylon Fitting Wire SUS304 Stainless Steel Braided Flexible Bathroom Toilet Hose 10+ Year Warranty 10 BAR incorporates design features specifically intended to maximize service life under real-world operating conditions. The multi-layer construction isolates different stress factors, allowing each material to perform its optimized function without compromising overall system integrity. This approach significantly extends replacement intervals compared to single-material hose designs.

The precision-molded nylon fittings feature reinforced stress concentration areas and smooth internal flow paths that minimize turbulence and pressure loss. These fittings maintain their dimensional stability over time, preventing the gradual loosening that can occur with traditional brass fittings subjected to thermal cycling. The combination of materials provides excellent vibration damping characteristics, reducing noise transmission through building structures.

Pressure Performance and Safety

The robust construction enables reliable operation under elevated pressure conditions while maintaining safety margins that exceed typical residential and commercial applications. The reinforced design provides consistent performance across varying pressure ranges, ensuring reliable water delivery whether connected to low-pressure gravity-fed systems or high-pressure municipal supplies. This versatility makes the hose suitable for diverse installation scenarios without requiring pressure-specific variants.

Applications & Use Cases

Modern bathroom installations increasingly require flexible plumbing solutions that accommodate complex layouts while maintaining aesthetic appeal. The Modern Inner EPDM Tube Nylon Fitting Wire SUS304 Stainless Steel Braided Flexible Bathroom Toilet Hose 10+ Year Warranty 10 BAR excels in toilet supply connections where space constraints and accessibility requirements make traditional rigid piping impractical. The flexibility allows for easy routing around obstacles while the premium materials ensure long-term reliability in this critical application.

Commercial restroom facilities benefit significantly from this advanced hose design, particularly in high-traffic environments where maintenance accessibility and replacement costs directly impact operational efficiency. The extended service life and robust construction reduce the frequency of maintenance interventions while the attractive appearance maintains professional aesthetics. Hotels, office buildings, and retail facilities find this solution particularly valuable for balancing initial investment with long-term operational costs.

Residential bathroom renovations often involve connecting new fixtures to existing plumbing configurations that may not align perfectly with modern fixture placement. This flexible hose system provides designers and contractors with greater layout flexibility while ensuring code compliance and long-term reliability. The premium appearance allows for exposed installations that complement contemporary bathroom designs without compromising functionality.

Industrial and institutional applications, including healthcare facilities and educational buildings, require plumbing components that can withstand intensive use while maintaining sanitary conditions. The smooth interior surfaces and chemical-resistant materials prevent bacterial growth and contamination while the robust construction withstands the demanding conditions typical of these environments.

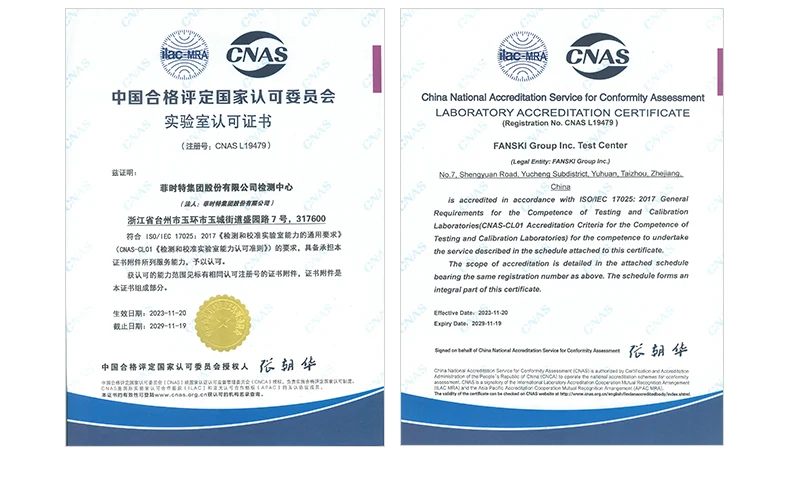

Quality Control & Compliance

Manufacturing excellence begins with rigorous material selection and continues through every stage of production. Each component undergoes comprehensive testing to verify dimensional accuracy, material properties, and performance characteristics before assembly. The EPDM tubing receives particular attention to ensure consistent wall thickness and chemical composition, as these factors directly impact long-term performance and safety.

The stainless steel braiding process incorporates precision controls that maintain consistent wire tension and coverage density across the entire hose length. This attention to detail ensures uniform pressure distribution and prevents the stress concentrations that can lead to premature failure. Quality control protocols include both automated inspection systems and manual verification procedures to identify any variations from specification requirements.

International plumbing standards and safety regulations guide the design and manufacturing processes, ensuring compatibility with global installation practices. The Modern Inner EPDM Tube Nylon Fitting Wire SUS304 Stainless Steel Braided Flexible Bathroom Toilet Hose 10+ Year Warranty 10 BAR meets or exceeds relevant performance criteria for pressure resistance, temperature range, and chemical compatibility. Regular third-party testing validates ongoing compliance with evolving industry standards.

Traceability systems maintain detailed records of material sources, production parameters, and quality test results for each manufacturing batch. This comprehensive documentation supports warranty claims and enables rapid identification of any potential issues that might emerge during service life. The quality management system incorporates continuous improvement processes that identify opportunities for enhanced performance and reliability.

Customization & Branding Options

Professional distributors and large-scale installers often require specific configurations that address unique installation requirements or brand identity needs. The flexible manufacturing approach accommodates various fitting types, thread specifications, and connection angles while maintaining the core performance characteristics that define this product line. Custom length options enable optimal installation efficiency without excess material or connection complications.

Private label opportunities allow established plumbing distributors to offer this advanced technology under their own brand identity while maintaining quality and warranty support. The manufacturing infrastructure supports custom packaging designs and product identification systems that reinforce brand recognition and customer loyalty. Technical documentation and installation guides can be customized to reflect specific brand standards and customer communication preferences.

Regional market requirements often necessitate specific certification marks, labeling formats, or compliance documentation. The flexible production system accommodates these variations without compromising manufacturing efficiency or quality standards. Custom packaging solutions protect the product during shipping while presenting a professional image that supports premium market positioning.

Packaging & Logistics Support

Efficient distribution requires packaging solutions that protect product integrity while optimizing shipping costs and handling efficiency. The Modern Inner EPDM Tube Nylon Fitting Wire SUS304 Stainless Steel Braided Flexible Bathroom Toilet Hose 10+ Year Warranty 10 BAR utilizes protective packaging designed to prevent damage during transit while minimizing dimensional requirements for cost-effective shipping. Individual product protection prevents scratching or contamination while maintaining the premium appearance expected by end users.

Bulk packaging options serve distributors and contractors who require larger quantities for ongoing projects or inventory management. These configurations balance protection requirements with space efficiency, enabling cost-effective distribution through various channels. The packaging design facilitates easy identification and inventory management while protecting against environmental factors that could affect product performance.

International shipping requirements receive careful attention through packaging designs that comply with various regulatory requirements while maintaining product protection. Documentation support includes technical specifications, installation guidance, and warranty information formatted for international markets. The logistics infrastructure supports flexible delivery schedules that align with customer project timelines and inventory management needs.

Why Choose Us

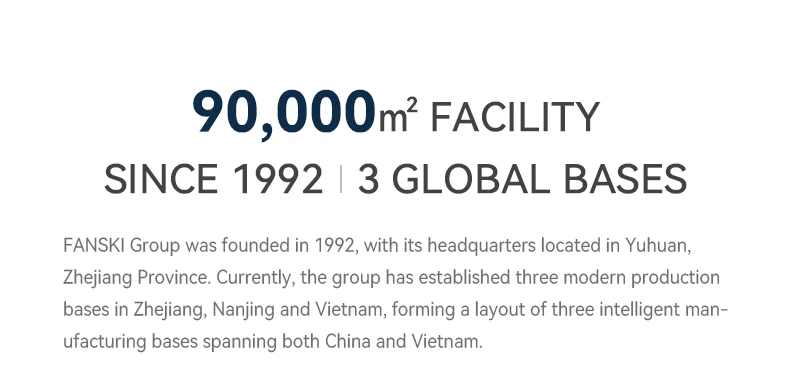

Our organization brings over many yearss of experience in developing advanced plumbing solutions for global markets, with established partnerships spanning six continents and expertise across residential, commercial, and industrial applications. This extensive background enables deep understanding of diverse market requirements and the technical challenges that drive continuous innovation in flexible hose technology. Our engineering teams collaborate with leading industry professionals to identify emerging needs and develop solutions that address both current requirements and future market evolution.

The manufacturing infrastructure incorporates state-of-the-art production technology with comprehensive quality management systems that ensure consistent performance across all product lines. Strategic partnerships with premium material suppliers enable access to the latest compound formulations and manufacturing techniques while maintaining cost competitiveness essential for global market success. This approach positions us as a reliable metal packaging supplier capable of meeting diverse customer requirements while maintaining exceptional quality standards.

Technical support services extend beyond product delivery to include installation guidance, troubleshooting assistance, and ongoing performance monitoring. Our global service network provides local language support and regional expertise while maintaining consistent technical standards across all markets. This comprehensive approach establishes long-term partnerships with distributors, contractors, and end users who value both product performance and ongoing support availability.

Research and development investments focus on emerging technologies and evolving market requirements, ensuring our product portfolio remains at the forefront of industry advancement. Collaboration with international standards organizations and industry associations provides early insight into regulatory changes and performance requirements that influence product design decisions. This proactive approach enables customers to specify products with confidence in their long-term viability and compliance status.

Conclusion

The Modern Inner EPDM Tube Nylon Fitting Wire SUS304 Stainless Steel Braided Flexible Bathroom Toilet Hose 10+ Year Warranty 10 BAR represents a significant advancement in flexible plumbing technology, combining premium materials with sophisticated engineering to deliver exceptional performance and longevity. The multi-layer construction optimizes each material's contribution to overall system performance while the attractive appearance complements contemporary design preferences. Professional contractors, facility managers, and distributors will find this solution addresses both immediate installation requirements and long-term operational objectives through its robust construction and extended service life. The comprehensive warranty support and global availability make this product an ideal choice for diverse applications where reliability, performance, and aesthetic appeal are essential considerations.

Product Name |

Stainless Steel Braided Hose |

Specification |

φ14 F1/2*F1/2 |

Length |

40cm/50cm/60cm/70cm/80cm/90cm/100cm/200cm/300cm |

Nominal Diameter |

DN10 |

Material of Inner Tube |

EPDM |

Material of End |

SUS304 Nylon |

Material of Wire |

SUS304 |

Working Pressure |

1.0Mpa |

Max Temperature |

90℃ |

Nut Torque |

60N.m |

Certificate |

DVGW |

WARRANTY |

20 Years |

LOSS COVERAGE/CASE/USD |

2 Million |

Logo |

Customized logo welcomed |

Packing |

Standard export package or customized |

A:Yes. we're professional manufacture in China,and have been in this field for more

than 30 years.

Q:What payment terms do you support?

A: T/T,L/C,DP,DDU,DDP etc are available, and for T/T we accept 30% deposit in advance,70% balance against copy of B/L.

A:In-stock items typically ship within a week. Out-of-stock items usually ship within 4-6 weeks, while custom orders depend on your specific design requirements.

Q:How long is your delivery time for the item without stock?

A:30-40 days after receiving deposit.

Q:ls it possible to get samples from your factory?

A:Yes. Free samples will be sent if needed, but the freight can be negotiated or chargeable, it will be refunded after

confirmation of the order.

Q:Can l use my own logo or design on your products?

A:Absolutely yes. We offer OEM/ODM services to customize products with your logo or design.

Q:Do you operate your own factories?

A:Yes, we have factories in Zhejiang and Vietnam. We also work closely with other reliable manufacturers to meet different needs.You' re welcome to visit us.

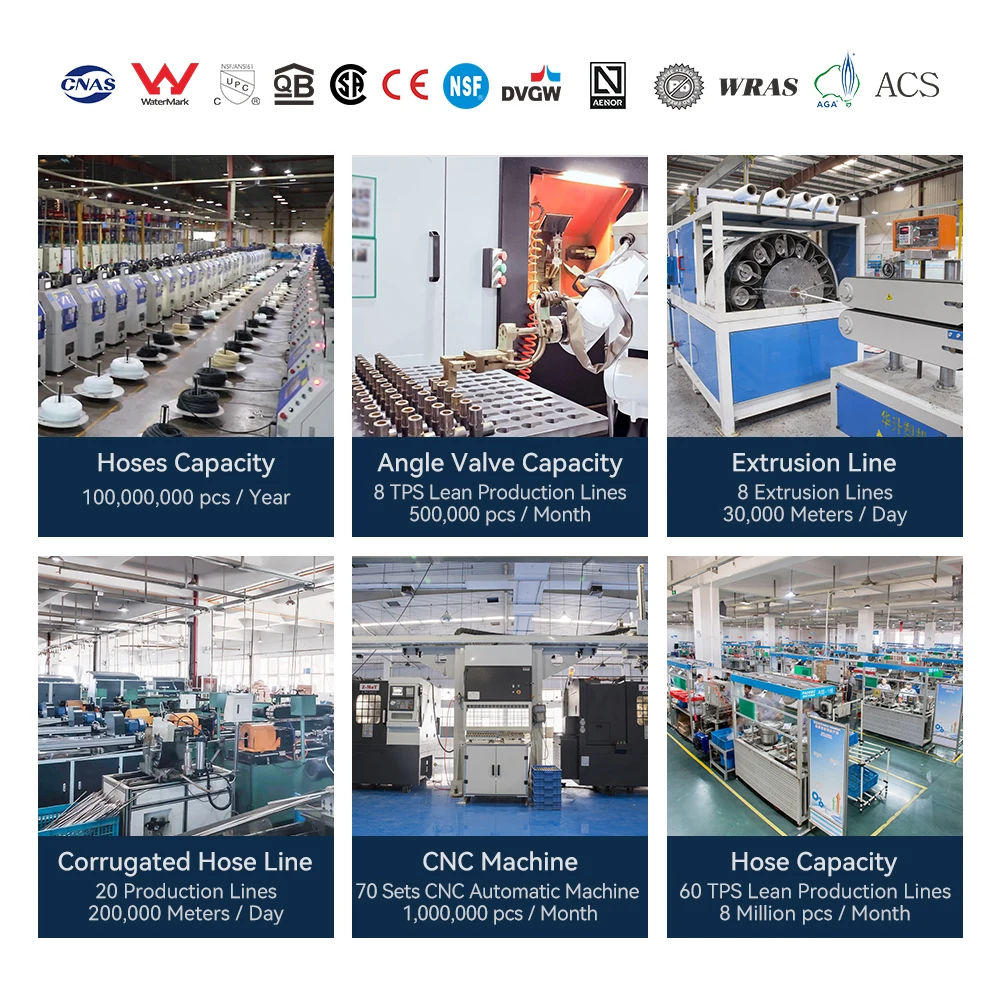

Q:What is your production capacity?

A:For the products of flexible hose,we can make 8 million pieces a month and for the angle valve,we can make 1.6 million pieces a month. We also maintain strong partnerships with other suppliers to ensure timely and reliable deliveries.

Q:How do you choose your suppliers?

A:We rigorously select suppliers based on their performance in domestic projects focusing on their production capacity, delivery reliability, and quality control. Our own quality team oversees this process.

A:Yes, we provide after-sales support with warranties ranging from 3 to 20 years depending on the product. Please contact us for more information.

Q:Do you accept small orders?

A:Yes, we welcome the orders that it may meet our requirement of MOQ for different products. We are committed to providing excellent service to every customer.