Introduction

The modern plumbing industry demands reliable, durable components that ensure seamless water flow and prevent costly leaks in residential and commercial applications. The PPW Brand Modern Design Nylon Wire Braided Flexible EPDM Inner Tube Gaskets for Kitchen Faucet/Tap Plumbing Hoses Comply British represents the pinnacle of engineering excellence in flexible plumbing solutions. These premium gaskets combine advanced materials technology with innovative design principles to deliver superior performance in demanding water distribution systems. Engineered to meet stringent British compliance standards, these gaskets provide the reliability and longevity that professional plumbers, contractors, and facility managers require for their most critical installations.

Modern kitchen environments present unique challenges for plumbing components, requiring products that can withstand temperature fluctuations, chemical exposure, and continuous mechanical stress. These specialized gaskets address these challenges through their sophisticated construction methodology, incorporating nylon wire braiding technology with flexible EPDM inner tube design. The result is a product that maintains structural integrity while providing the flexibility necessary for diverse installation scenarios and operational conditions.

Product Overview

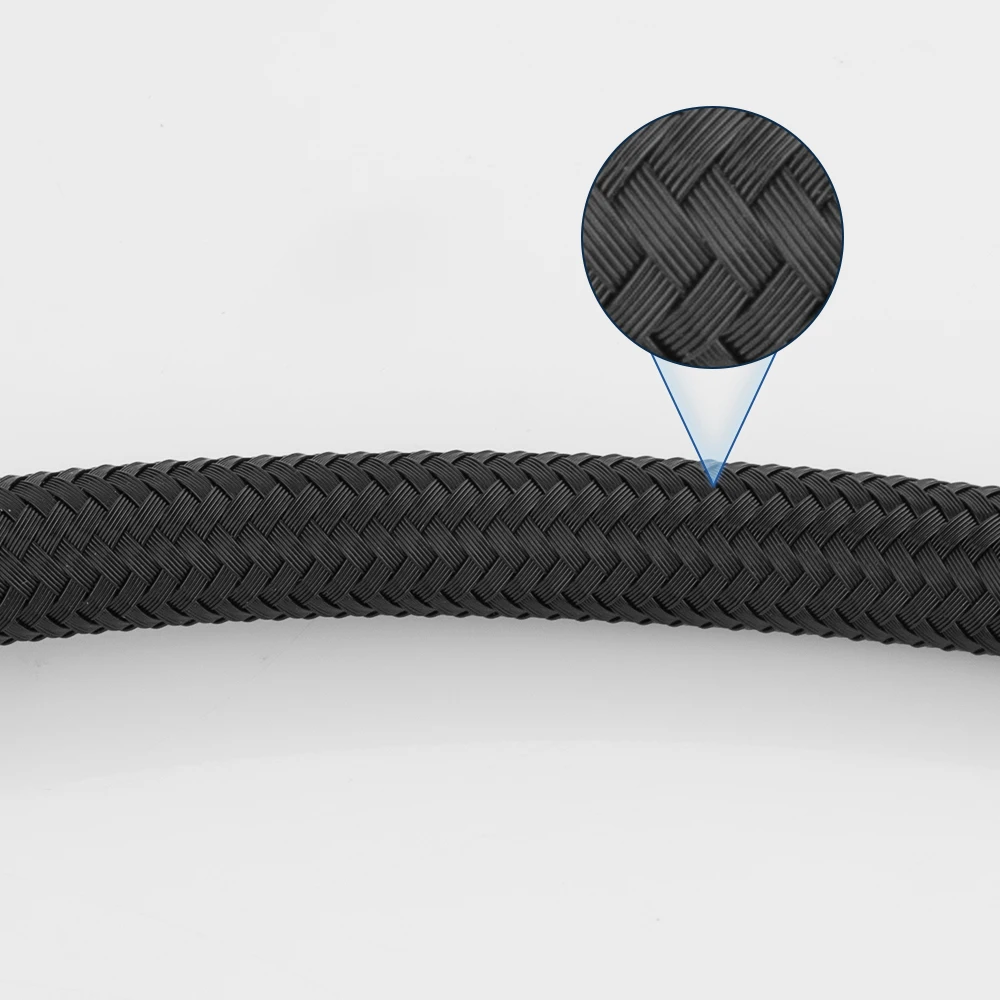

The PPW Brand gaskets feature a revolutionary multi-layer construction that combines the tensile strength of nylon wire braiding with the chemical resistance and flexibility of EPDM rubber materials. This innovative design approach creates a product that excels in both static and dynamic applications, making it ideal for kitchen faucet connections, tap assemblies, and various plumbing hose configurations. The modern design philosophy behind these gaskets emphasizes both functional performance and aesthetic integration with contemporary plumbing fixtures.

Each gasket undergoes precision manufacturing processes that ensure consistent quality and dimensional accuracy across production runs. The nylon wire braiding provides exceptional burst resistance and structural support, while the EPDM inner tube offers excellent sealing properties and chemical compatibility with potable water systems. This combination of materials creates a product that maintains its sealing effectiveness over extended service periods, reducing maintenance requirements and minimizing system downtime.

The flexible nature of these gaskets allows for easy installation in confined spaces and challenging routing scenarios commonly encountered in modern kitchen designs. Their compatibility with various fitting types and connection methods makes them versatile solutions for both new construction projects and retrofit applications where existing plumbing systems require upgrading or repair.

Features & Benefits

Advanced Material Technology

The integration of nylon wire braiding technology represents a significant advancement in gasket construction methodology. This braiding system provides uniform stress distribution across the gasket surface, preventing localized failure points that can compromise sealing integrity. The nylon fibers maintain their strength characteristics across a wide temperature range, ensuring consistent performance in varying operational conditions. The wire reinforcement creates a balanced structure that resists both internal pressure forces and external mechanical stresses.

EPDM rubber selection for the inner tube component reflects careful consideration of material properties essential for plumbing applications. This synthetic rubber compound exhibits excellent resistance to water, steam, and common cleaning chemicals encountered in kitchen environments. The material maintains its flexibility and sealing properties over extended temperature ranges, making it suitable for both hot and cold water applications. Additionally, EPDM demonstrates superior aging characteristics, maintaining its physical properties over many years of service.

Modern Design Integration

The contemporary design approach of these PPW Brand gaskets considers both functional requirements and aesthetic compatibility with modern plumbing fixtures. The sleek profile and professional finish complement the visual design of premium kitchen faucets and tap assemblies. This attention to visual integration ensures that the gaskets enhance rather than detract from the overall appearance of high-end plumbing installations.

Flexibility remains a cornerstone of the design philosophy, enabling these gaskets to accommodate various installation configurations without compromising sealing effectiveness. The balanced construction allows for natural movement and adjustment during installation, reducing the risk of installation-related damage while ensuring proper sealing engagement. This flexibility also accommodates thermal expansion and contraction cycles common in plumbing systems.

Applications & Use Cases

Kitchen faucet installations represent the primary application domain for these specialized gaskets, where their combination of flexibility and sealing performance proves invaluable. Modern kitchen designs often feature complex under-counter routing requirements that demand gaskets capable of following irregular paths while maintaining leak-free connections. The PPW Brand gaskets excel in these challenging installations, providing reliable sealing even in applications involving multiple directional changes and space constraints.

Tap plumbing systems in commercial environments benefit significantly from the durability and chemical resistance characteristics of these gaskets. Restaurant kitchens, institutional food service facilities, and commercial washroom installations subject plumbing components to intensive use patterns and exposure to various cleaning chemicals. The EPDM inner tube construction ensures compatibility with these demanding operating conditions while the nylon wire braiding provides the structural integrity necessary for high-frequency operation cycles.

Residential plumbing renovations and new construction projects find these gaskets particularly valuable for their ease of installation and long-term reliability. The flexible design accommodates the dimensional variations commonly encountered when connecting new fixtures to existing plumbing infrastructure. Professional plumbers appreciate the consistent quality and predictable performance characteristics that reduce callback risks and enhance customer satisfaction.

Specialty applications in water filtration systems, beverage dispensing equipment, and laboratory plumbing installations benefit from the chemical compatibility and precision sealing capabilities of these gaskets. The British compliance standards ensure suitability for potable water applications while the robust construction provides confidence in critical system installations where leak prevention is paramount.

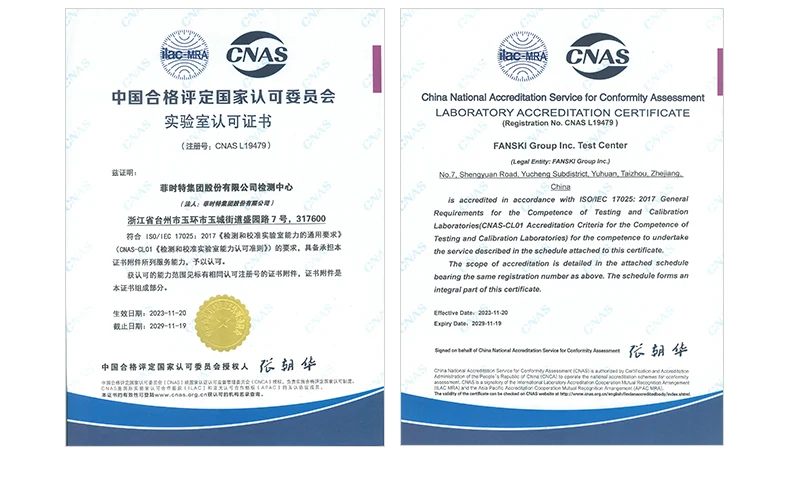

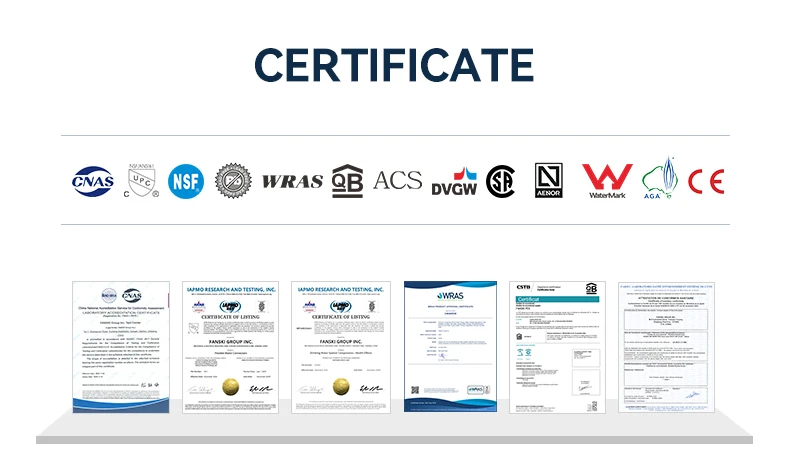

Quality Control & Compliance

British compliance standards represent some of the most stringent quality requirements in the global plumbing industry, encompassing material safety, performance characteristics, and manufacturing consistency. The PPW Brand Modern Design Nylon Wire Braided Flexible EPDM Inner Tube Gaskets for Kitchen Faucet/Tap Plumbing Hoses Comply British standards through comprehensive testing protocols that verify material composition, dimensional accuracy, and performance under simulated service conditions.

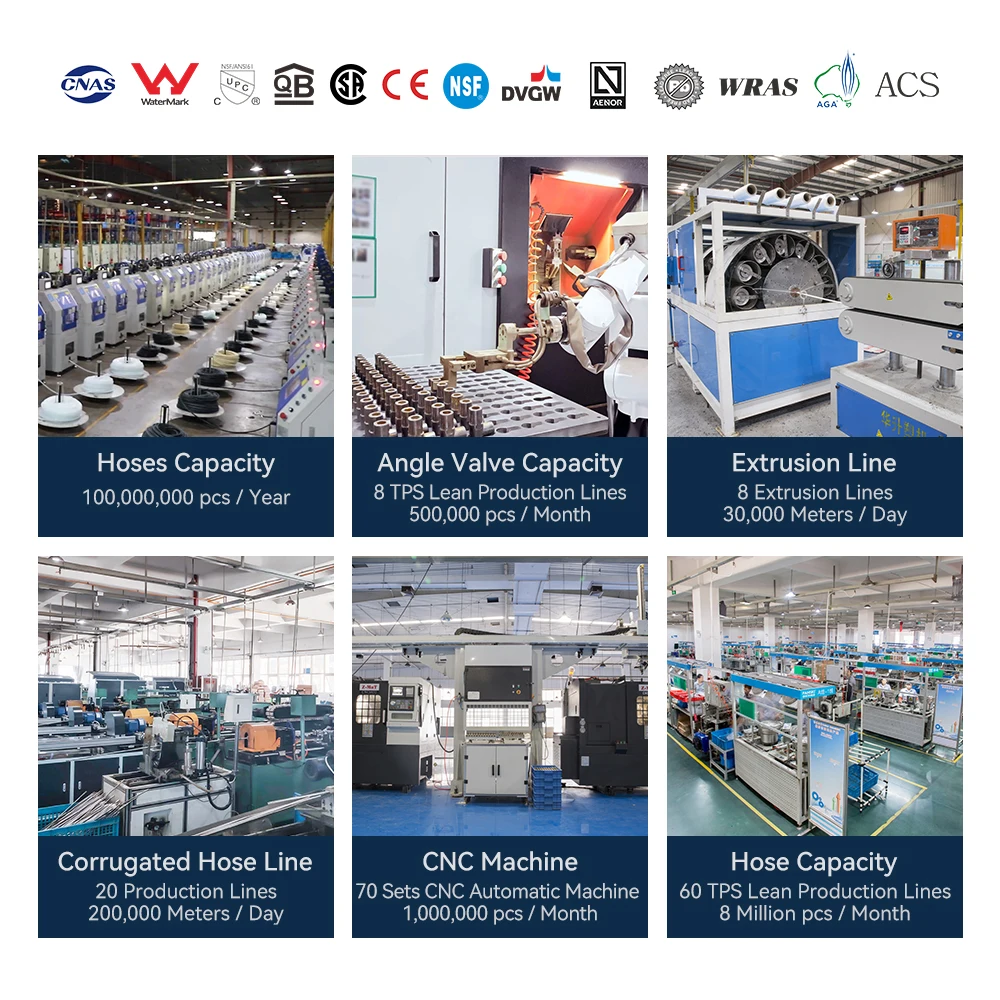

Manufacturing quality control processes incorporate multiple inspection points throughout the production cycle, ensuring that each gasket meets established specifications before packaging. Raw material verification confirms that both nylon wire and EPDM rubber components meet purity and performance standards essential for potable water applications. The braiding process undergoes continuous monitoring to maintain consistent wire tension and uniform coverage patterns that contribute to structural integrity.

Performance testing protocols evaluate sealing effectiveness, pressure resistance, temperature stability, and chemical compatibility under conditions that exceed typical service requirements. These rigorous testing procedures provide confidence in product performance while identifying potential improvements in design or manufacturing processes. Long-term aging studies validate the durability claims and help predict service life under various operating conditions.

Documentation systems maintain comprehensive records of material sources, production parameters, and quality test results for each production batch. This traceability system supports quality investigations when required and provides valuable data for continuous improvement initiatives. Regular audits of manufacturing processes ensure continued compliance with British standards and identify opportunities for enhanced quality control measures.

Customization & Branding Options

Understanding that different markets and applications may require specific adaptations, the PPW Brand gasket line offers various customization possibilities to meet unique project requirements. Custom dimensions and configurations can be developed to address specialized installation scenarios or compatibility requirements with specific fixture manufacturers. The flexible manufacturing approach allows for modifications in braiding patterns, EPDM compound formulations, and overall gasket geometry while maintaining compliance with British standards.

Private labeling opportunities enable distributors and system integrators to offer these premium gaskets under their own brand identity. Professional packaging design services support brand positioning efforts while maintaining the quality image essential for premium plumbing components. Custom packaging configurations can accommodate different distribution channels and storage requirements while protecting product integrity during transportation and handling.

Technical support services assist customers in developing application-specific solutions that optimize gasket performance for particular use cases. Engineering consultation helps identify the most appropriate gasket configuration for challenging installations while ensuring compliance with relevant standards and regulations. This collaborative approach often leads to innovative solutions that benefit the broader market through improved product offerings.

Packaging & Logistics Support

Professional packaging systems protect gasket integrity during transportation while facilitating efficient handling throughout the distribution chain. Each gasket receives individual protection to prevent damage from handling and environmental exposure during storage and shipment. Bulk packaging options accommodate the needs of large-scale installations while maintaining easy access for individual gasket selection and installation.

Inventory management support helps distributors optimize stock levels while ensuring product availability for time-sensitive projects. Flexible packaging configurations accommodate different order quantities and shipping requirements, from small repair jobs to major construction projects. Clear product identification and technical information on packaging facilitate proper selection and installation procedures.

International shipping expertise ensures that products reach global markets in optimal condition while meeting various customs and regulatory requirements. Comprehensive documentation supports smooth customs clearance processes while providing the technical information required by international buyers and regulatory authorities. This global logistics capability enables PPW Brand gaskets to serve plumbing professionals worldwide with consistent quality and reliable availability.

Why Choose Us

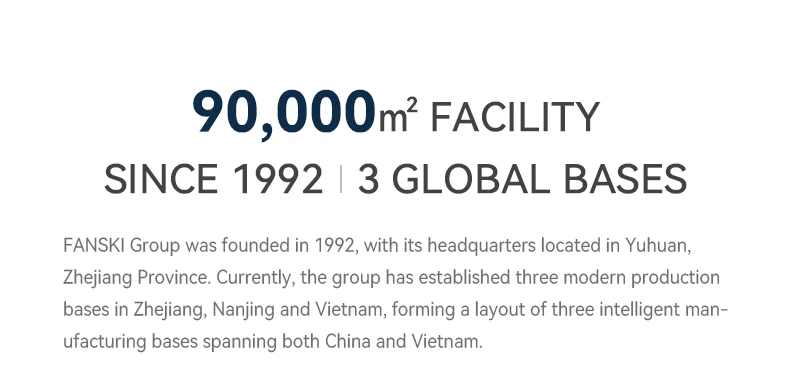

With extensive experience serving international markets across multiple continents, our organization has developed deep expertise in manufacturing premium plumbing components that meet diverse regional requirements and standards. This global perspective enables us to understand the unique challenges faced by plumbers, contractors, and facility managers in different markets while maintaining consistent quality standards across all product lines. Our commitment to excellence has earned recognition from industry professionals who depend on reliable performance in their most demanding applications.

As a recognized metal packaging supplier and custom solutions provider, we bring advanced manufacturing capabilities and quality control expertise to every product line, including these specialized gaskets. Our comprehensive understanding of materials science and precision manufacturing techniques ensures that each PPW Brand gasket delivers the performance characteristics essential for professional plumbing applications. This multi-industry expertise enables innovative approaches to product development and continuous improvement initiatives.

Collaboration with international partners and distributors has created a global network that supports reliable product availability and technical support services. Professional installation support and application guidance help ensure optimal gasket performance while reducing installation time and potential complications. Our commitment to customer success extends beyond product delivery to include ongoing technical assistance and problem-solving support when challenges arise in the field.

Continuous investment in research and development maintains our position at the forefront of gasket technology while anticipating future market requirements and regulatory changes. This forward-thinking approach ensures that PPW Brand products continue to meet evolving industry standards while incorporating the latest advances in materials science and manufacturing techniques. Our dedication to innovation benefits customers through improved product performance and enhanced value in their plumbing system investments.

Conclusion

The PPW Brand Modern Design Nylon Wire Braided Flexible EPDM Inner Tube Gaskets for Kitchen Faucet/Tap Plumbing Hoses Comply British represent the convergence of advanced materials technology, innovative design principles, and rigorous quality standards. These premium gaskets address the demanding requirements of modern plumbing systems through their sophisticated construction methodology and proven performance characteristics. The combination of nylon wire braiding strength with EPDM flexibility creates products that excel in both demanding commercial applications and precision residential installations. Professional plumbers, contractors, and facility managers can rely on these gaskets to provide long-term sealing performance while accommodating the challenging installation scenarios common in contemporary construction projects. The British compliance standards ensure suitability for potable water applications while the robust manufacturing processes guarantee consistent quality across all production runs. Through careful attention to both functional requirements and aesthetic integration, these gaskets enhance the overall quality and reliability of modern plumbing systems while supporting the professional reputation of those who specify and install them.