Introduction

Modern plumbing systems demand reliable, flexible connections that can withstand daily use while maintaining superior sealing performance. The PPW Modern Design Nylon Wire Braided Flexible Brass Nipple Nut EPDM Inner Tube Gaskets for Kitchen Faucet/Tap Plumbing Hoses represents the pinnacle of contemporary plumbing connector technology, combining innovative materials engineering with practical design excellence. This advanced plumbing component addresses the critical need for durable, leak-resistant connections in residential and commercial kitchen installations, offering professional installers and distributors a premium solution that exceeds traditional connector limitations.

Engineered specifically for demanding kitchen environments, these flexible brass connectors integrate multiple high-performance materials to deliver exceptional longevity and reliability. The sophisticated construction methodology ensures optimal performance across diverse installation scenarios, making these connectors an indispensable component for modern plumbing applications. Professional contractors and wholesale distributors recognize the importance of selecting components that provide consistent performance while simplifying installation procedures, characteristics that define this exceptional product line.

Product Overview

The PPW Modern Design flexible connector system incorporates a sophisticated multi-layer construction that maximizes both durability and flexibility. The core design features a precision-manufactured brass nipple nut that provides robust mechanical connection strength while maintaining compatibility with standard plumbing fixtures. This brass component undergoes specialized manufacturing processes to ensure dimensional accuracy and corrosion resistance, critical factors for long-term performance in kitchen environments where exposure to various water conditions is common.

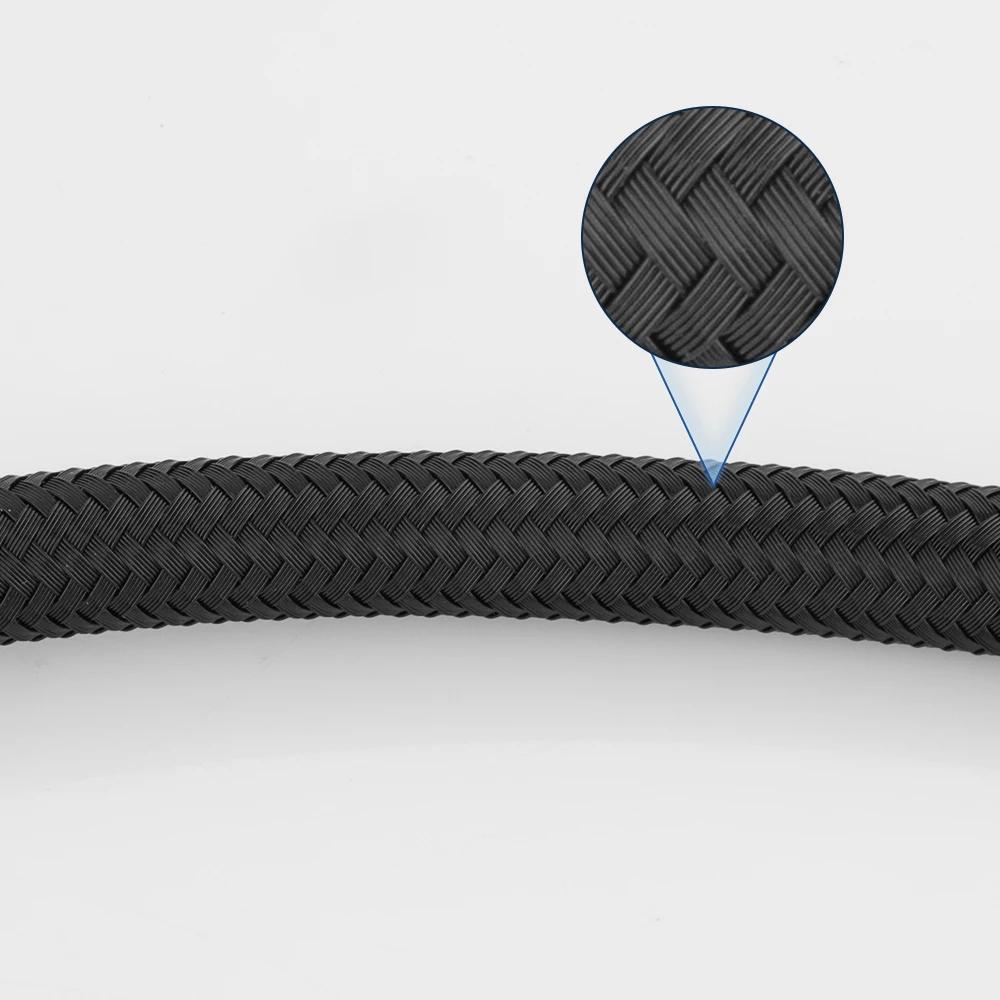

The innovative nylon wire braiding system forms the backbone of this connector's exceptional flexibility and strength characteristics. This advanced braiding technique creates a protective outer layer that resists kinking, crushing, and abrasion while allowing the connector to bend smoothly around obstacles during installation. The EPDM inner tube gaskets represent another crucial component, providing superior sealing performance across temperature variations and chemical exposures typical in kitchen plumbing applications. These gaskets maintain their elasticity and sealing properties over extended periods, reducing maintenance requirements and ensuring consistent leak-free operation.

Features & Benefits

Advanced Material Engineering

The PPW Modern Design Nylon Wire Braided Flexible Brass Nipple Nut EPDM Inner Tube Gaskets for Kitchen Faucet/Tap Plumbing Hoses incorporates carefully selected materials that work synergistically to deliver exceptional performance. The brass construction provides excellent corrosion resistance and mechanical strength, ensuring reliable connections that withstand the pressures and stresses encountered in typical kitchen plumbing systems. The precision machining of these brass components guarantees consistent thread engagement and optimal sealing surface contact, contributing to leak-free installations.

The nylon wire braiding system represents a significant advancement in flexible connector design, offering superior protection against external damage while maintaining excellent flexibility characteristics. This braiding technology distributes stress evenly across the connector length, preventing localized failure points that commonly affect inferior designs. The EPDM inner tube gasket material provides exceptional chemical resistance and temperature stability, maintaining its sealing properties across the wide range of conditions encountered in kitchen environments.

Enhanced Installation Flexibility

Professional installers appreciate the enhanced flexibility that these connectors provide during installation procedures. The sophisticated design allows for easy routing around obstacles, through tight spaces, and around corners without compromising the integrity of the connection or reducing flow characteristics. This flexibility significantly reduces installation time while improving the overall quality of the plumbing system, factors that translate directly into improved project efficiency and customer satisfaction.

The connector design also accommodates variations in fixture positioning and alignment, providing installers with greater latitude during the installation process. This adaptability proves particularly valuable in renovation projects where existing plumbing configurations may not align perfectly with new fixture requirements. The robust construction ensures that the connectors maintain their performance characteristics even when installed in challenging configurations, providing long-term reliability regardless of installation constraints.

Applications & Use Cases

Kitchen faucet and tap installations represent the primary application for these advanced flexible connectors, where their superior performance characteristics address the specific challenges encountered in food preparation environments. The connectors excel in both residential and commercial kitchen installations, providing reliable connections that withstand the frequent use patterns and varying water pressures typical in these applications. Professional installers regularly specify these connectors for high-end residential projects where long-term reliability and minimal maintenance are critical requirements.

Commercial kitchen environments present particularly demanding conditions, including higher usage frequencies, temperature variations, and exposure to cleaning chemicals. The PPW Modern Design flexible connectors demonstrate exceptional performance in these challenging applications, maintaining their sealing integrity and mechanical strength over extended periods. Restaurant and institutional kitchen installations benefit significantly from the reduced maintenance requirements and extended service life that these connectors provide, factors that contribute directly to operational efficiency and cost control.

Beyond primary kitchen applications, these versatile connectors find extensive use in auxiliary plumbing connections including prep sinks, bar areas, and specialty kitchen equipment installations. The flexibility and reliability characteristics make them ideal for installations where space constraints or complex routing requirements challenge conventional rigid connections. Wholesale distributors serving the commercial plumbing market recognize these connectors as essential components for projects requiring premium performance and reliability.

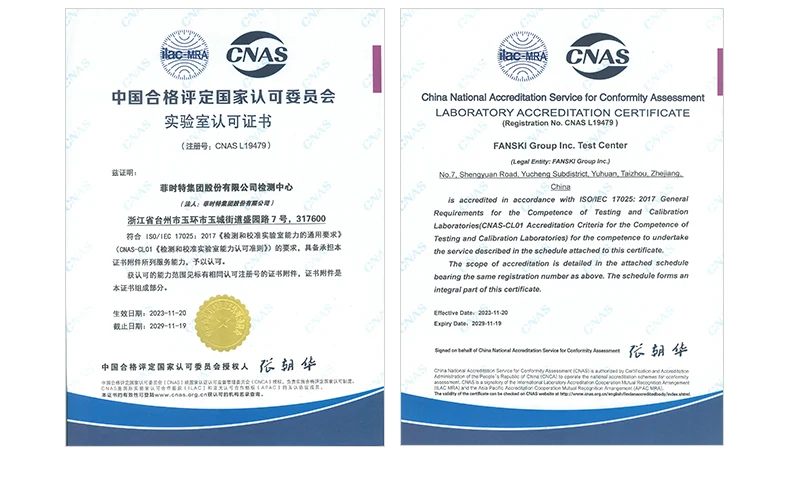

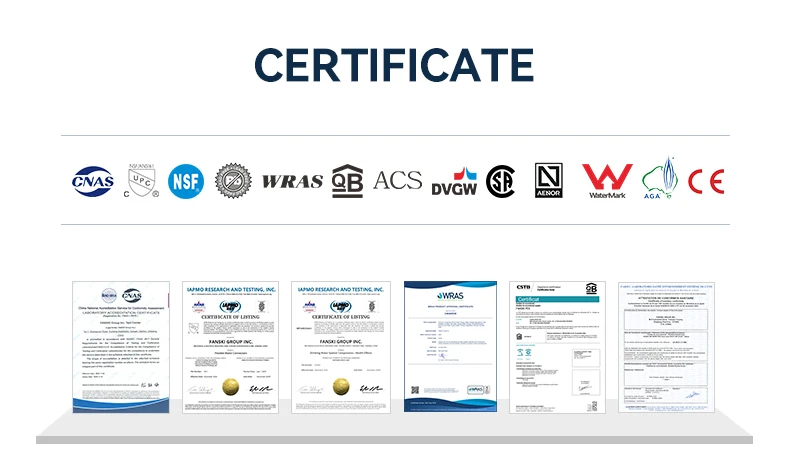

Quality Control & Compliance

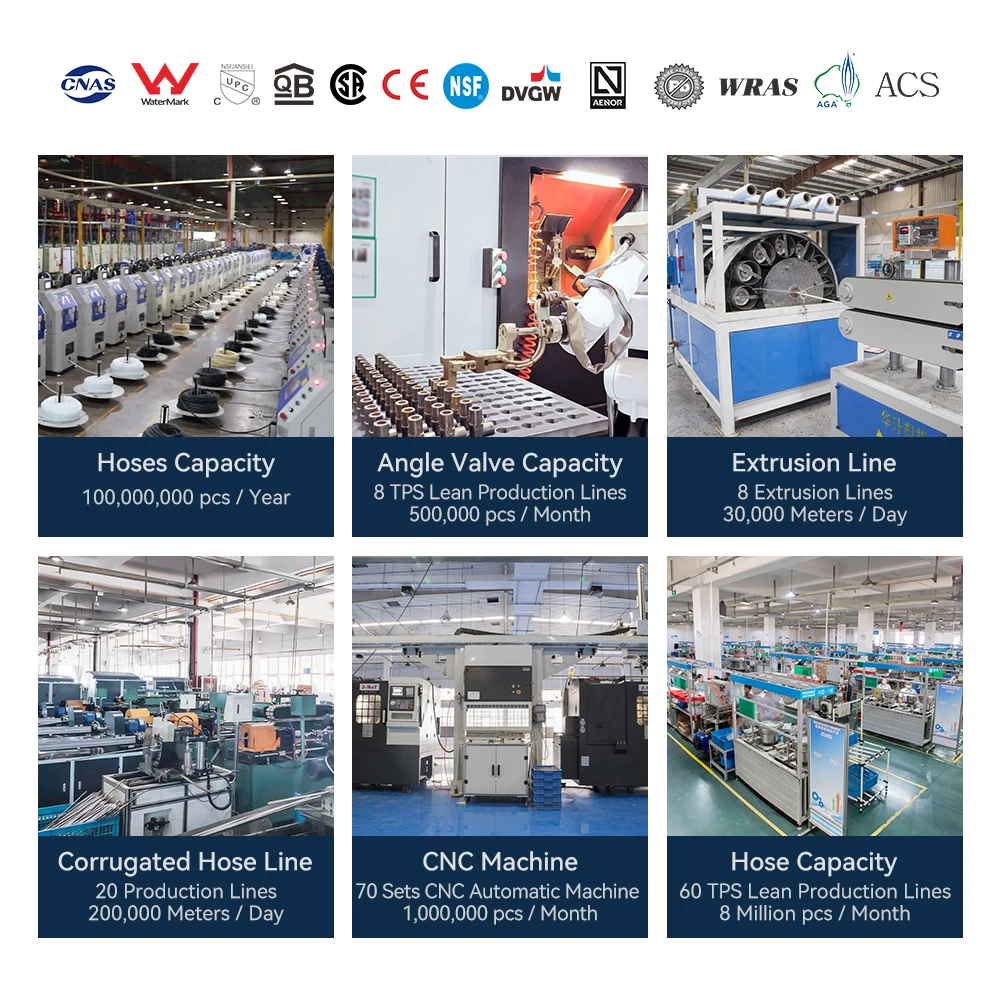

Manufacturing excellence forms the foundation of the PPW Modern Design connector quality program, with comprehensive testing protocols ensuring that each component meets rigorous performance standards. The quality control process encompasses material verification, dimensional accuracy testing, and performance validation under simulated service conditions. These extensive testing procedures guarantee that the connectors deliver consistent performance characteristics across all production batches, providing distributors and installers with confidence in product reliability.

Compliance with international plumbing standards represents a critical aspect of the product development process, ensuring compatibility with diverse market requirements and installation practices. The connectors undergo evaluation against relevant performance standards, including pressure testing, temperature cycling, and chemical resistance assessment. This comprehensive compliance program enables successful deployment across multiple international markets while maintaining consistent quality expectations.

The manufacturing facility maintains advanced quality management systems that ensure consistent adherence to established quality parameters throughout the production process. Regular audits and continuous improvement initiatives maintain the highest quality standards while incorporating technological advances that enhance product performance. This commitment to quality excellence has established strong relationships with professional distributors and installers who depend on consistent product performance for their business success.

Customization & Branding Options

Professional distributors and private label customers benefit from comprehensive customization capabilities that enable tailored solutions for specific market requirements. The flexible manufacturing approach accommodates various packaging configurations, labeling requirements, and product specifications while maintaining the core performance characteristics that define these premium connectors. Custom packaging solutions help distributors establish distinctive market positioning while ensuring product protection during transportation and storage.

Branding customization options enable qualified partners to develop their own product lines while leveraging the proven performance and quality characteristics of the PPW Modern Design platform. These partnerships combine established manufacturing excellence with local market expertise, creating value-added solutions that meet specific regional requirements. The customization program includes technical support and documentation services that facilitate successful product introduction and market development activities.

Technical specification modifications can be accommodated for large-volume applications or specialized market segments that require unique performance characteristics. The engineering team collaborates closely with customers to develop optimized solutions that address specific application requirements while maintaining the quality and reliability standards that define the product line. This collaborative approach has resulted in numerous successful custom solutions for demanding applications across various market segments.

Packaging & Logistics Support

Comprehensive packaging solutions protect the PPW Modern Design Nylon Wire Braided Flexible Brass Nipple Nut EPDM Inner Tube Gaskets for Kitchen Faucet/Tap Plumbing Hoses throughout the distribution chain while facilitating efficient handling and inventory management. The packaging design incorporates protective materials that prevent damage during transportation while minimizing package dimensions to optimize shipping efficiency. Professional-grade packaging ensures that products reach end customers in perfect condition, supporting the quality reputation that distributors depend on for business success.

Logistics support services streamline the supply chain process for international distributors and wholesale customers, providing reliable delivery schedules and flexible shipping options that accommodate diverse business requirements. The logistics team coordinates closely with shipping partners to ensure efficient customs processing and documentation for international shipments. Advanced inventory management systems enable responsive order fulfillment while maintaining optimal stock levels that support consistent product availability.

Distribution support extends beyond basic logistics to include technical documentation, installation guides, and marketing materials that help distributors effectively serve their customer base. Comprehensive product information and technical specifications enable distributors to provide knowledgeable customer service while supporting professional installers with the information needed for successful installations. This integrated support approach strengthens distribution partnerships while enhancing end-customer satisfaction with product performance and installation experience.

Why Choose Us

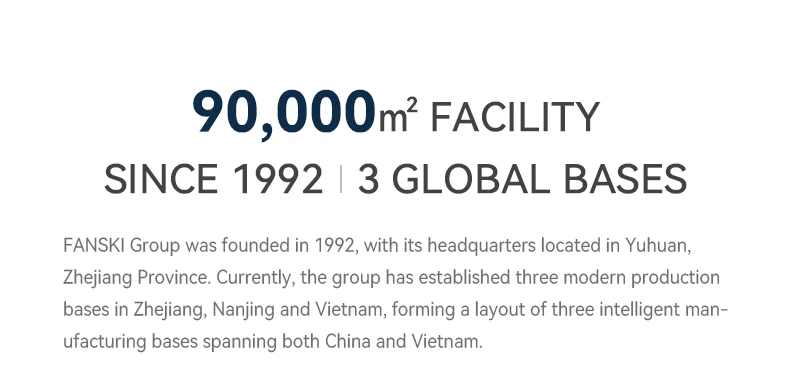

Our company brings extensive experience in precision manufacturing and international market development, with established relationships serving professional distributors and contractors across multiple continents. This global presence enables deep understanding of diverse market requirements and quality expectations, knowledge that directly influences product development and manufacturing excellence. As a recognized metal packaging manufacturer and supplier, we apply the same rigorous quality standards and manufacturing expertise to our plumbing component lines, ensuring consistent excellence across all product categories.

The commitment to innovation and continuous improvement drives ongoing investment in advanced manufacturing technology and quality control systems that maintain our position as a leading supplier in competitive international markets. Our multi-industry expertise enables cross-pollination of technological advances and manufacturing techniques, resulting in superior products that exceed customer expectations. Professional distributors and custom tin box supplier partners recognize the value of working with a manufacturer that combines technical excellence with reliable business practices and responsive customer service.

Strategic partnerships with qualified distributors and wholesale customers create mutual success through collaborative product development, market expansion, and technical support initiatives. Our experienced team provides comprehensive support throughout the business relationship, from initial product evaluation through ongoing technical assistance and business development activities. This partnership approach has established strong, long-term relationships with successful distributors who appreciate the combination of product excellence and business support that drives their market success.

Conclusion

The PPW Modern Design Nylon Wire Braided Flexible Brass Nipple Nut EPDM Inner Tube Gaskets for Kitchen Faucet/Tap Plumbing Hoses represents the optimal choice for professional installers, distributors, and contractors who demand superior performance and reliability in their plumbing systems. The sophisticated multi-material construction combines the strength and corrosion resistance of precision brass components with the flexibility and protection of advanced nylon wire braiding and the sealing excellence of EPDM gasket technology. This integration creates a connector system that exceeds the performance capabilities of conventional alternatives while providing the installation flexibility and long-term reliability that modern plumbing applications require. The comprehensive quality control program, extensive customization options, and professional support services establish this product line as the preferred choice for demanding applications where performance, reliability, and value creation are essential success factors.