Introduction

The modern plumbing industry demands reliable, flexible, and durable connection solutions that can withstand the rigorous demands of residential and commercial washing machine installations. The PPW Washing Machine Inlet Hose Flexible Plumbing Hoses F3/4" X F3/4" + Elbow PVC Inner Tube Nylon Connector represents a superior engineering solution designed to meet these exacting requirements. This innovative plumbing component combines advanced material technology with precision manufacturing to deliver exceptional performance in water supply applications.

Professional installers, distributors, and facility managers worldwide recognize the critical importance of selecting high-quality inlet hoses that provide both flexibility and durability. The PPW Washing Machine Inlet Hose Flexible Plumbing Hoses F3/4" X F3/4" + Elbow PVC Inner Tube Nylon Connector addresses these needs through its sophisticated design architecture that incorporates premium materials and advanced construction techniques to ensure long-lasting, leak-free operation in demanding environments.

Product Overview

This comprehensive plumbing solution features a meticulously engineered design that integrates multiple high-performance components into a single, cohesive unit. The hose assembly incorporates a flexible PVC inner tube construction that provides excellent chemical resistance and maintains structural integrity under varying pressure conditions. The nylon connector components are specifically selected for their superior strength characteristics and corrosion resistance properties, ensuring reliable performance across diverse installation environments.

The elbow configuration integrated into the PPW Washing Machine Inlet Hose Flexible Plumbing Hoses F3/4" X F3/4" + Elbow PVC Inner Tube Nylon Connector provides essential spatial flexibility for installations where space constraints or directional requirements demand precise positioning. This thoughtful design consideration significantly reduces installation complexity while maintaining optimal flow characteristics throughout the water supply system.

Manufacturing excellence is evident in every aspect of this product, from the precision-molded connector components to the carefully calibrated flexibility characteristics of the hose assembly. The female threaded connections are engineered to exacting tolerances, ensuring consistent sealing performance and compatibility with standard plumbing fixtures and appliances.

Features & Benefits

Advanced Material Engineering

The core construction of this washing machine inlet hose utilizes premium-grade PVC formulation specifically developed for potable water applications. This specialized material composition provides exceptional resistance to chemical degradation, temperature fluctuations, and mechanical stress while maintaining flexibility across a wide range of operating conditions. The inner tube construction ensures smooth water flow characteristics and minimizes pressure loss throughout the system.

Nylon connector components deliver superior mechanical strength and dimensional stability compared to traditional materials. The engineering-grade nylon formulation resists thread wear, provides excellent torque retention, and maintains sealing integrity even under repeated installation and maintenance cycles. This material selection significantly extends service life and reduces the frequency of replacement requirements.

Flexible Installation Solutions

The integrated elbow design of the PPW Washing Machine Inlet Hose Flexible Plumbing Hoses F3/4" X F3/4" + Elbow PVC Inner Tube Nylon Connector eliminates the need for additional fittings in applications requiring directional changes. This streamlined approach reduces potential leak points, simplifies installation procedures, and provides enhanced reliability in confined spaces where traditional straight connections prove impractical.

Flexibility characteristics are carefully engineered to provide optimal bend radius capabilities without compromising structural integrity or flow performance. The hose maintains consistent cross-sectional area throughout its length, ensuring uniform pressure distribution and minimizing turbulence that could affect appliance performance or create noise during operation.

Precision Threading and Sealing

Female threading on both ends ensures compatibility with standard washing machine connections and supply valve configurations. Thread geometry is manufactured to precise specifications, providing secure engagement while minimizing installation torque requirements. This design approach reduces the risk of over-tightening damage while ensuring reliable sealing performance across diverse installation scenarios.

Applications & Use Cases

Residential washing machine installations represent the primary application for this versatile plumbing component. The PPW Washing Machine Inlet Hose Flexible Plumbing Hoses F3/4" X F3/4" + Elbow PVC Inner Tube Nylon Connector excels in both new construction and retrofit applications where space limitations or configuration requirements demand flexible connection solutions. The elbow design proves particularly valuable in laundry rooms with tight clearances or where appliances must be positioned close to walls or cabinetry.

Commercial laundry facilities benefit significantly from the enhanced durability and reliability characteristics of this product. High-frequency usage patterns in commercial environments demand components that can withstand repeated pressure cycling, temperature variations, and mechanical stress without degradation. The robust construction and premium materials ensure consistent performance in these demanding applications.

Multi-unit residential developments, including apartments, condominiums, and student housing facilities, require plumbing components that provide long-term reliability with minimal maintenance requirements. The PPW Washing Machine Inlet Hose Flexible Plumbing Hoses F3/4" X F3/4" + Elbow PVC Inner Tube Nylon Connector addresses these needs through its durable construction and simplified installation characteristics, reducing both initial installation costs and ongoing maintenance expenses.

Hospitality industry applications, including hotels, extended-stay facilities, and vacation rentals, benefit from the reliable performance and aesthetic considerations inherent in this design. The compact elbow configuration allows for cleaner installations while the premium materials ensure consistent operation across varying usage patterns and maintenance schedules.

Quality Control & Compliance

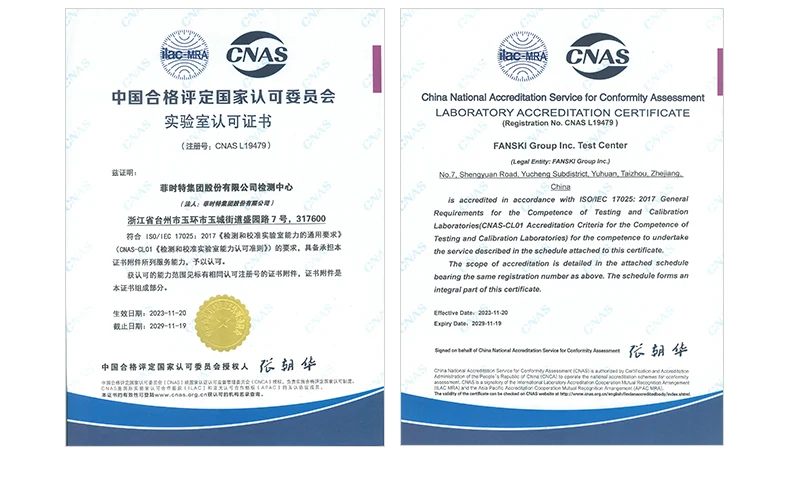

Manufacturing processes incorporate comprehensive quality control protocols that ensure every unit meets stringent performance and safety standards. Material testing procedures verify chemical composition, mechanical properties, and dimensional accuracy before components enter the production process. In-process monitoring systems continuously evaluate critical parameters to maintain consistent quality throughout manufacturing operations.

Pressure testing protocols simulate real-world operating conditions to validate sealing performance and structural integrity under various load scenarios. These comprehensive testing procedures ensure that each PPW Washing Machine Inlet Hose Flexible Plumbing Hoses F3/4" X F3/4" + Elbow PVC Inner Tube Nylon Connector meets or exceeds industry performance benchmarks before shipment to customers worldwide.

International compliance requirements are addressed through adherence to recognized industry standards and certification programs. Material certifications verify compatibility with potable water applications, while performance certifications validate pressure ratings and safety characteristics. This comprehensive approach to compliance ensures global acceptability and provides customers with confidence in product performance and safety.

Traceability systems maintain detailed records throughout the manufacturing process, enabling rapid identification and resolution of any quality concerns that may arise. This systematic approach to quality management demonstrates our commitment to continuous improvement and customer satisfaction across all markets and applications.

Customization & Branding Options

Professional distributors and importers can leverage comprehensive customization capabilities to differentiate their product offerings and strengthen brand recognition in competitive markets. Our experienced engineering team collaborates with partners to develop modified configurations that address specific market requirements or application needs while maintaining the core performance characteristics that define this product line.

Private labeling services enable distributors to establish strong brand presence through customized packaging and product identification options. These services include package design consultation, brand integration, and market-specific compliance documentation to ensure seamless market entry and customer acceptance across diverse geographical regions.

As a recognized metal packaging manufacturer with extensive experience in custom packaging solutions, our organization provides comprehensive support for product presentation and protection requirements. Custom tin packaging solutions can be developed to enhance product appeal while providing superior protection during storage and transportation phases.

Technical customization options allow modification of specific performance parameters to address unique application requirements or regional preferences. Our engineering capabilities support development of specialized configurations while maintaining the quality standards and reliability characteristics that define our product portfolio.

Packaging & Logistics Support

Professional packaging solutions protect product integrity throughout global distribution networks while optimizing storage and handling efficiency. Individual product packaging incorporates protective materials and design elements that prevent damage during transportation while facilitating easy identification and inventory management for distributors and retailers.

Bulk packaging configurations are engineered to maximize shipping efficiency while maintaining product protection standards. These solutions reduce per-unit packaging costs and environmental impact while streamlining warehouse operations for high-volume distributors and importers.

Our metal packaging supplier capabilities extend to development of specialized shipping containers and protective packaging systems for sensitive markets or challenging distribution environments. These custom solutions ensure product quality maintenance across extended supply chains while optimizing logistics costs and efficiency.

Documentation support includes comprehensive product specifications, installation guides, and compliance certifications in multiple languages to facilitate international distribution. Technical support materials are regularly updated to reflect current standards and best practices, ensuring customers have access to accurate, relevant information throughout the product lifecycle.

Why Choose Us

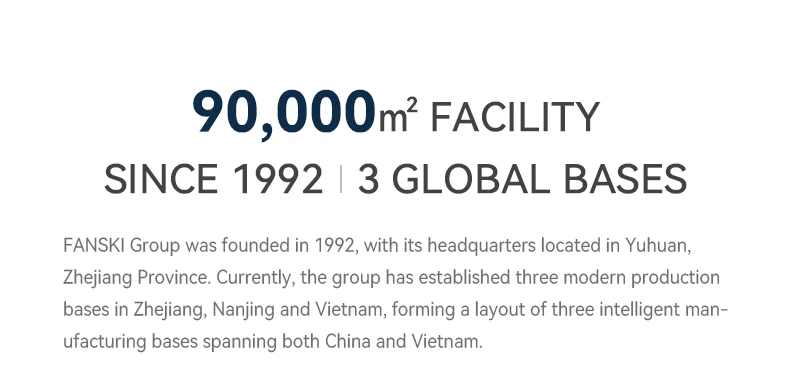

Our organization brings decades of experience in precision manufacturing and international market development to every product we produce. With established operations across multiple continents and partnerships with leading distributors worldwide, we understand the diverse requirements and expectations of global markets. This international perspective enables us to develop products that meet universal quality standards while addressing regional preferences and compliance requirements.

Technical expertise spans multiple industries, from plumbing components to specialized packaging solutions. This broad experience base enables innovative approaches to product development and manufacturing that consistently deliver superior performance and reliability. Our engineering teams collaborate closely with market partners to ensure product designs meet evolving industry requirements and customer expectations.

As an established OEM tin packaging solutions provider, our organization demonstrates versatility and capability across diverse manufacturing disciplines. This multi-industry expertise translates into enhanced quality control processes, innovative material applications, and comprehensive understanding of global supply chain requirements that benefit all product categories.

Commitment to continuous improvement drives ongoing investment in manufacturing technology, quality systems, and customer support capabilities. This dedication ensures that our products consistently meet the highest standards while our service capabilities evolve to address changing market needs and customer expectations across all geographical regions.

Conclusion

The PPW Washing Machine Inlet Hose Flexible Plumbing Hoses F3/4" X F3/4" + Elbow PVC Inner Tube Nylon Connector represents the convergence of advanced materials engineering, precision manufacturing, and practical design innovation. This comprehensive plumbing solution addresses the critical requirements of modern washing machine installations through its flexible configuration, durable construction, and reliable performance characteristics. The integrated elbow design eliminates installation complications while the premium PVC inner tube and nylon connector construction ensure long-term reliability in diverse operating environments. Professional installers, distributors, and facility managers worldwide can depend on this product to deliver consistent performance and simplified installation procedures that reduce both initial costs and ongoing maintenance requirements. The combination of technical excellence, manufacturing quality, and comprehensive support services establishes this product as the preferred choice for demanding plumbing applications across residential, commercial, and industrial markets globally.

Product Name |

Washing Machine Water Inlet Hose |

Specification |

φ16 F3/4*F3/4 with Elbow |

Length |

120cm / 200cm |

Nominal Diameter |

DN10 |

Material of Inner Tube |

PVC |

Working Pressure |

1.0Mpa |

Max Temperature |

70℃ |

Nut Torque |

25N.m |

WARRANTY |

10 Years |

LOSS COVERAGE/CASE/USD |

2 Million |

Logo |

Customized logo welcomed |

Packing |

Standard export package or customized |

A:Yes. we're professional manufacture in China,and have been in this field for more

than 30 years.

Q:What payment terms do you support?

A: T/T,L/C,DP,DDU,DDP etc are available, and for T/T we accept 30% deposit in advance,70% balance against copy of B/L.

A:In-stock items typically ship within a week. Out-of-stock items usually ship within 4-6 weeks, while custom orders depend on your specific design requirements.

Q:How long is your delivery time for the item without stock?

A:30-40 days after receiving deposit.

Q:ls it possible to get samples from your factory?

A:Yes. Free samples will be sent if needed, but the freight can be negotiated or chargeable, it will be refunded after

confirmation of the order.

Q:Can l use my own logo or design on your products?

A:Absolutely yes. We offer OEM/ODM services to customize products with your logo or design.

Q:Do you operate your own factories?

A:Yes, we have factories in Zhejiang and Vietnam. We also work closely with other reliable manufacturers to meet different needs.You' re welcome to visit us.

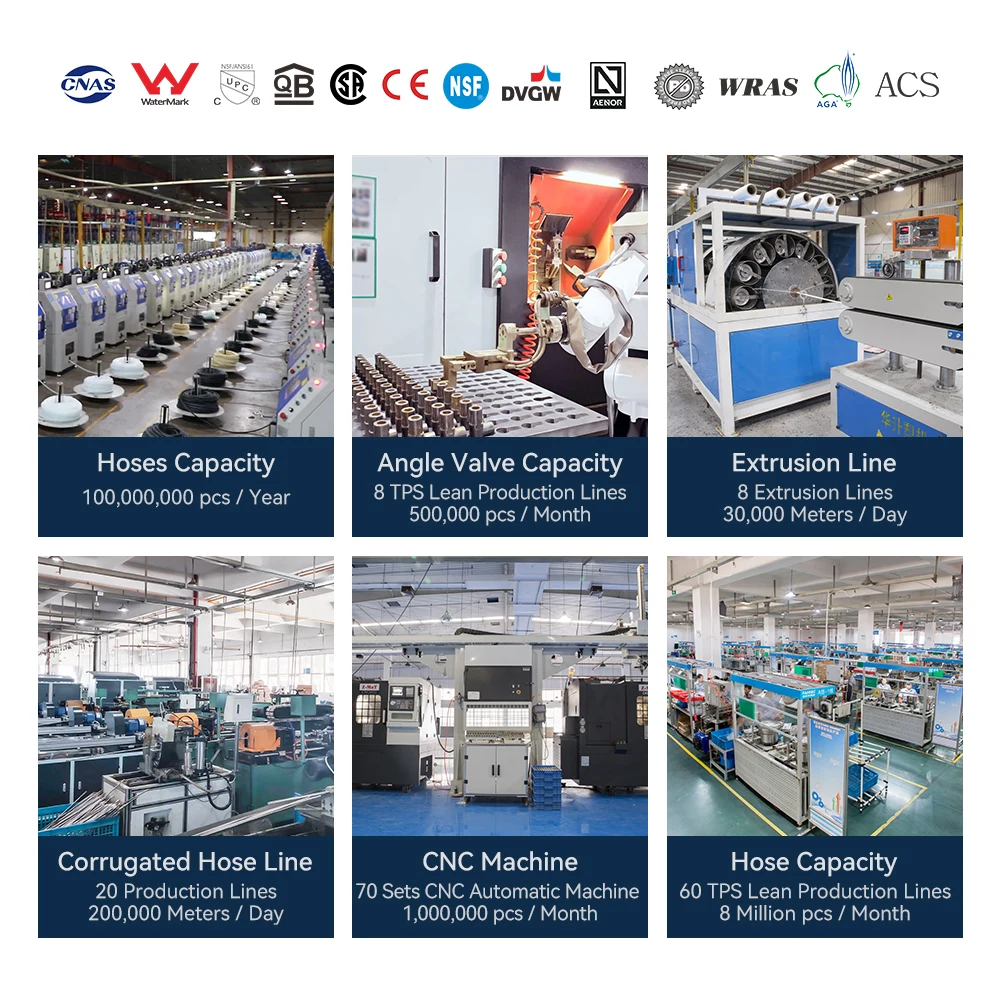

Q:What is your production capacity?

A:For the products of flexible hose,we can make 8 million pieces a month and for the angle valve,we can make 1.6 million pieces a month. We also maintain strong partnerships with other suppliers to ensure timely and reliable deliveries.

Q:How do you choose your suppliers?

A:We rigorously select suppliers based on their performance in domestic projects focusing on their production capacity, delivery reliability, and quality control. Our own quality team oversees this process.

A:Yes, we provide after-sales support with warranties ranging from 3 to 20 years depending on the product. Please contact us for more information.

Q:Do you accept small orders?

A:Yes, we welcome the orders that it may meet our requirement of MOQ for different products. We are committed to providing excellent service to every customer.