Introduction

In today's demanding plumbing and heating systems, reliable water flow control remains paramount for residential, commercial, and industrial applications. The Brass 1/2 Inch Universal Angle Valve Toilet Water Heater Thickened Manual Ball Cold Hot Valve represents a breakthrough in precision-engineered flow control technology, combining traditional brass craftsmanship with modern manufacturing excellence. This universal angle valve delivers exceptional performance across temperature ranges while maintaining structural integrity under varying pressure conditions.

Designed specifically for versatile installation requirements, this manual ball valve system addresses the growing market demand for durable, user-friendly plumbing components that seamlessly integrate with existing infrastructure. The thickened construction methodology ensures enhanced longevity while the universal angle design accommodates diverse mounting configurations across multiple application scenarios.

Product Overview

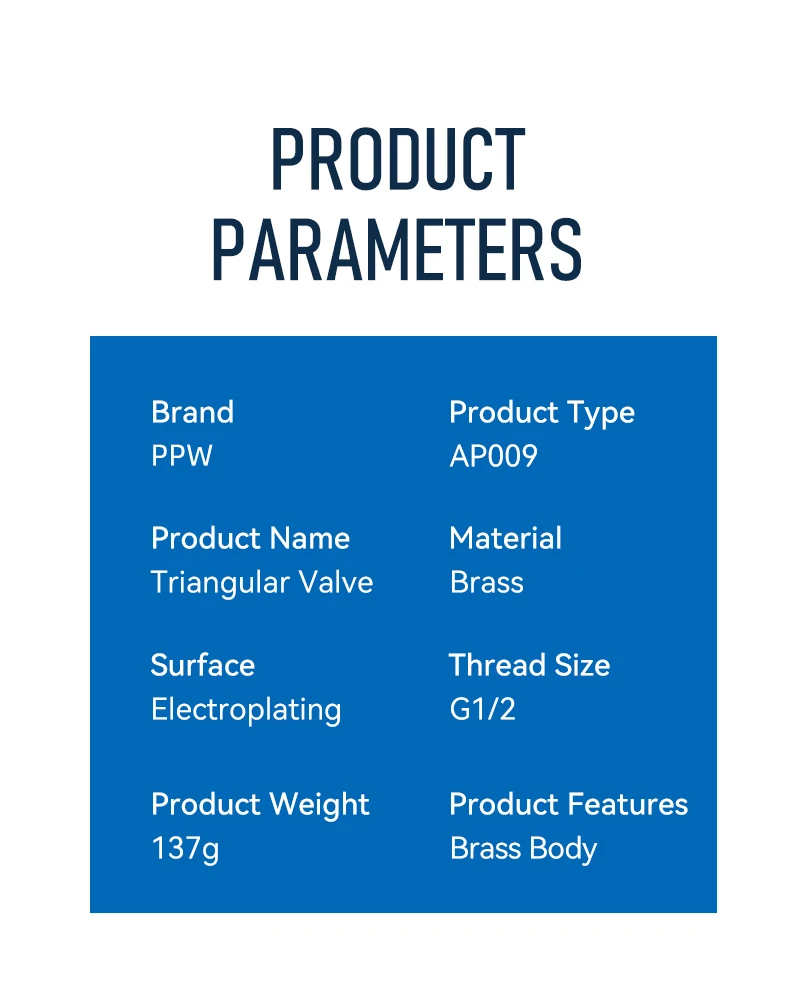

The Brass 1/2 Inch Universal Angle Valve Toilet Water Heater Thickened Manual Ball Cold Hot Valve stands as a testament to advanced metallurgical engineering and precision manufacturing processes. Constructed from premium brass alloy materials, this valve combines corrosion resistance with mechanical durability to deliver consistent performance across extended operational periods. The universal angle configuration enables flexible installation positioning while maintaining optimal flow characteristics.

This manual ball valve system incorporates a sophisticated internal mechanism designed to handle both cold and hot water applications with equal proficiency. The thickened wall construction provides enhanced structural stability, reducing the likelihood of deformation under thermal cycling or pressure fluctuations. The valve body features precision-machined threads and sealing surfaces that ensure leak-free connections throughout the product lifecycle.

The integrated handle mechanism offers intuitive operation with positive positioning feedback, allowing users to achieve precise flow control with minimal effort. The quarter-turn operation provides rapid shutoff capability while the smooth ball rotation ensures consistent performance even after extended periods of inactivity.

Features & Benefits

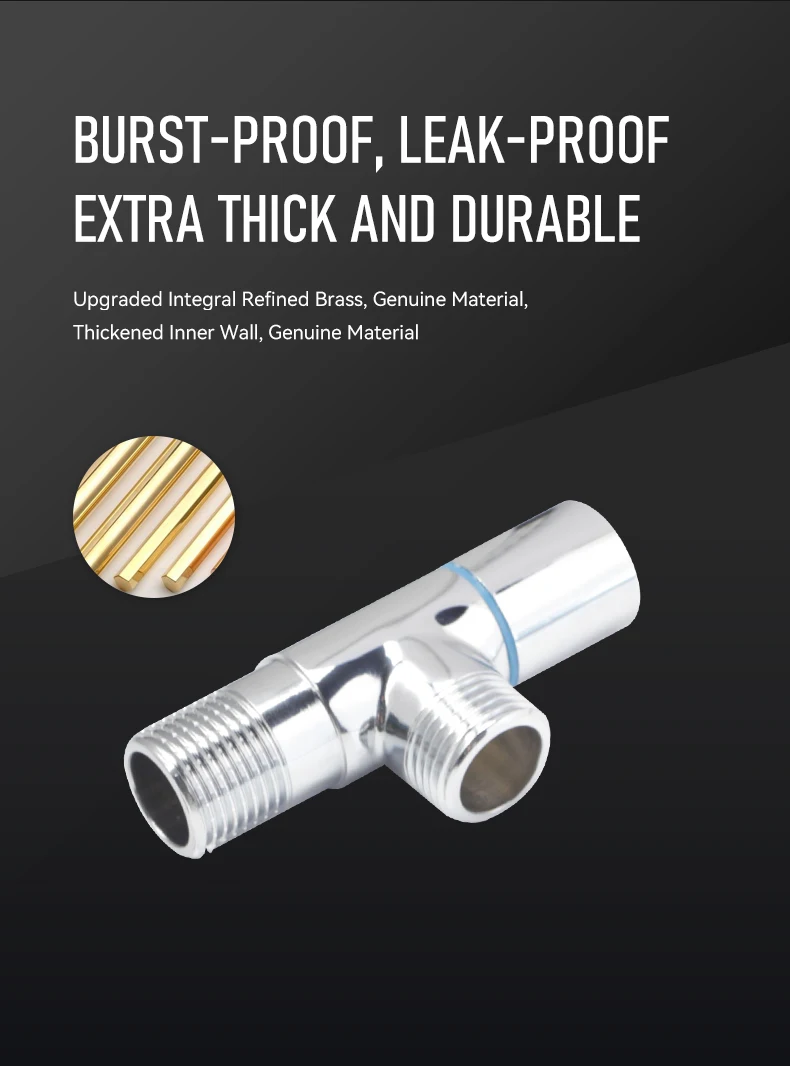

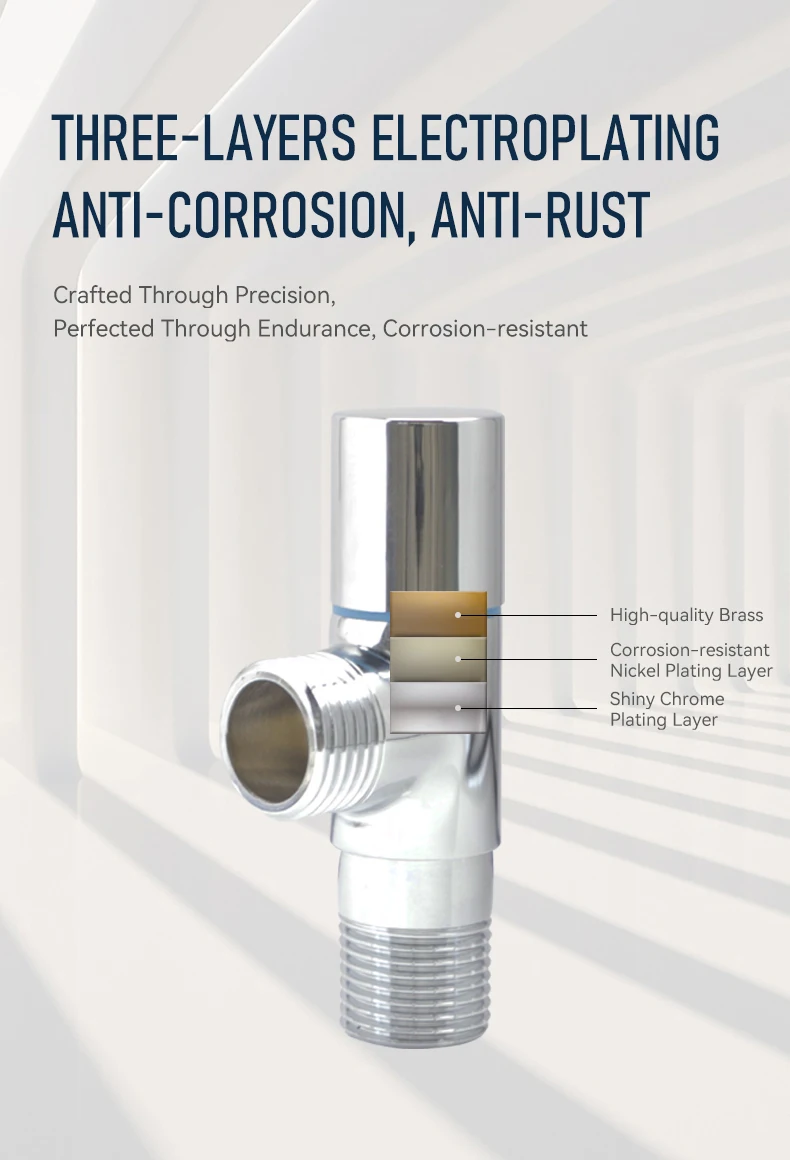

Advanced Brass Construction

The foundation of this angle valve lies in its premium brass construction, utilizing high-grade copper-zinc alloys that provide exceptional corrosion resistance and mechanical strength. This material selection ensures compatibility with various water chemistries while maintaining dimensional stability across temperature ranges. The brass composition naturally resists dezincification and stress corrosion cracking, common failure modes in lesser-quality valve materials.

Universal Angle Design Versatility

The universal angle configuration of this valve system accommodates diverse installation requirements without compromising flow efficiency. This design flexibility reduces inventory complexity for distributors while providing installers with greater mounting options. The angled body orientation optimizes space utilization in confined installation environments while maintaining accessibility for maintenance operations.

Thickened Wall Technology

The thickened construction methodology employed in this valve design significantly enhances structural integrity and pressure-handling capabilities. This engineering approach distributes mechanical stresses more effectively throughout the valve body, reducing concentrated stress points that could lead to premature failure. The increased material thickness also provides improved thermal mass, contributing to more stable operation during temperature transitions.

Manual Ball Operation Excellence

The manual ball valve mechanism delivers precise flow control through a polished sphere that rotates within precision-machined sealing surfaces. This design minimizes friction while ensuring reliable sealing performance across the operational temperature range. The ball construction utilizes materials specifically selected for dimensional stability and chemical compatibility with both hot and cold water applications.

Applications & Use Cases

The Brass 1/2 Inch Universal Angle Valve Toilet Water Heater Thickened Manual Ball Cold Hot Valve serves multiple application scenarios across residential, commercial, and industrial sectors. In residential plumbing systems, this valve provides reliable shutoff capability for toilet installations, water heater connections, and general fixture supply lines. The universal angle design proves particularly valuable in retrofit applications where space constraints or existing piping configurations require flexible mounting solutions.

Commercial applications benefit from the valve's robust construction and reliable operation in high-usage environments. Office buildings, hotels, and institutional facilities rely on this valve type for consistent water supply control to restroom facilities and service areas. The thickened construction provides the durability necessary for frequent operation cycles while maintaining leak-free performance under varying demand conditions.

Industrial applications leverage the valve's temperature handling capabilities for process water systems, equipment cooling circuits, and utility connections. The brass construction offers chemical compatibility with various industrial water treatments while the manual operation provides positive shutoff capability during maintenance procedures. The universal angle design accommodates complex piping arrangements common in industrial installations.

Water heater installations represent a primary application focus, where the valve's dual temperature capability proves essential for safe and efficient operation. The thickened construction withstands thermal cycling associated with heating system operation while the manual ball design provides reliable isolation during service procedures.

Quality Control & Compliance

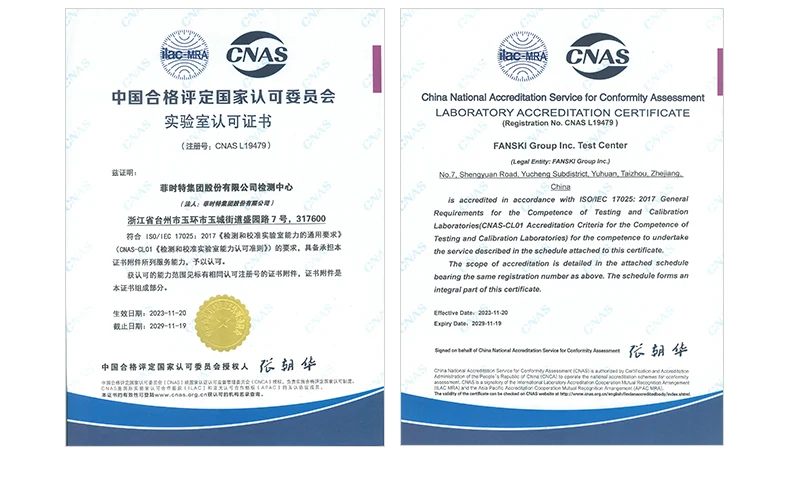

Manufacturing excellence forms the cornerstone of this valve's quality assurance program, incorporating comprehensive testing protocols and material verification procedures. Each valve undergoes pressure testing to verify structural integrity and sealing performance under simulated operating conditions. The brass material composition receives verification through spectroscopic analysis to ensure compliance with industry standards for mechanical properties and corrosion resistance.

The production process incorporates multiple inspection points where dimensional accuracy, surface finish quality, and assembly integrity receive thorough evaluation. Thread conformity testing ensures proper fit with standard plumbing connections while valve operation testing verifies smooth handle movement and positive positioning. These quality control measures guarantee consistent performance across production batches.

Environmental compliance considerations guide material selection and manufacturing processes, ensuring the valve meets current regulations regarding lead content and other restricted substances. The brass alloy formulation complies with drinking water safety standards while maintaining the mechanical properties necessary for reliable valve operation.

Traceability systems track materials and components throughout the manufacturing process, enabling rapid identification and resolution of any quality concerns. This systematic approach to quality management ensures each valve meets stringent performance criteria before reaching end users.

Customization & Branding Options

Understanding the diverse requirements of global markets, our manufacturing capabilities extend beyond standard production to encompass comprehensive customization solutions. The Brass 1/2 Inch Universal Angle Valve Toilet Water Heater Thickened Manual Ball Cold Hot Valve serves as a foundation platform for various modification options that address specific market requirements or application demands.

Surface finish customization allows for different aesthetic presentations while maintaining the underlying performance characteristics. Options include various plating treatments, protective coatings, and surface textures that enhance both appearance and functionality. These modifications can address specific environmental conditions or installation requirements while preserving the valve's core operational capabilities.

Handle design variations accommodate different operational preferences and installation constraints. Custom handle configurations can incorporate specific grip patterns, color coding, or dimensional modifications that improve usability in particular applications. These customizations maintain the quarter-turn operation principle while adapting to unique user requirements.

Packaging and marking customization supports private label requirements and regional market preferences. Custom packaging designs can incorporate distributor branding while protective packaging modifications address specific shipping or storage requirements. Product marking customization includes various identification methods that support inventory management and traceability requirements.

Packaging & Logistics Support

Our comprehensive packaging solutions protect product integrity throughout the global supply chain while optimizing shipping efficiency and storage requirements. Each valve receives individual protective packaging that prevents damage during handling and transportation while maintaining product cleanliness until installation. The packaging design accommodates various shipping methods and storage conditions commonly encountered in international distribution.

Bulk packaging options provide cost-effective solutions for high-volume orders while maintaining individual product protection. These packaging systems optimize container utilization and reduce overall shipping costs while ensuring products arrive in perfect condition. The packaging materials selection considers environmental impact while providing necessary protection levels.

Documentation and labeling systems support efficient inventory management and product identification throughout the distribution process. Clear product identification, specification information, and handling instructions facilitate proper handling and storage by distributors and installers. These systems comply with various international labeling requirements and support traceability throughout the supply chain.

Logistics support extends beyond packaging to encompass shipment planning and delivery coordination that meets distributor requirements. Flexible shipping arrangements accommodate various order sizes and delivery schedules while maintaining cost efficiency. This comprehensive approach to logistics support ensures reliable product availability for end users.

Why Choose Us

With over many yearss of experience in precision valve manufacturing and global market presence, our company has established itself as a trusted partner for distributors and importers worldwide. Our commitment to manufacturing excellence combines traditional craftsmanship with modern production technologies to deliver consistently superior products that meet evolving market demands.

Our manufacturing capabilities extend beyond standard valve production to encompass comprehensive solutions that address diverse market requirements. As an experienced metal packaging manufacturer, we understand the importance of protecting products throughout the distribution process. Our custom tin box supplier capabilities enable us to provide integrated packaging solutions that enhance product presentation while ensuring protection during transportation and storage.

The company's multi-industry expertise enables us to understand diverse application requirements and develop solutions that address specific market needs. Our OEM tin packaging solutions demonstrate our ability to adapt manufacturing processes to meet unique customer requirements while maintaining quality standards. This flexibility extends to valve manufacturing where we can accommodate various customization requests without compromising performance.

Our global collaboration approach ensures we remain current with international standards and market trends while maintaining competitive manufacturing costs. This combination of technical expertise, manufacturing capability, and market understanding positions us as a preferred metal packaging supplier and valve manufacturer for distributors seeking reliable, high-quality products.

Quality assurance programs incorporate international best practices and continuous improvement methodologies that ensure consistent product performance. Our commitment to customer success extends throughout the product lifecycle, from initial design consultation through ongoing technical support and product development.

Conclusion

The Brass 1/2 Inch Universal Angle Valve Toilet Water Heater Thickened Manual Ball Cold Hot Valve represents the convergence of traditional manufacturing excellence with modern engineering innovation. This valve system delivers reliable performance across diverse applications while providing the flexibility and durability required for contemporary plumbing and heating systems. The combination of premium brass construction, universal angle design, and thickened wall technology creates a product that addresses current market demands while anticipating future requirements. For distributors and importers seeking a reliable valve solution that combines proven performance with manufacturing excellence, this angle valve system offers the quality, versatility, and support necessary for successful market penetration and customer satisfaction.